Non-glue tail sealing device for roll

A reel and plastic sealing technology, which is applied in the field of production and processing equipment for rolled materials, can solve problems such as low efficiency, inability to form a seal at the end of the reel, and affecting the effect of the seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

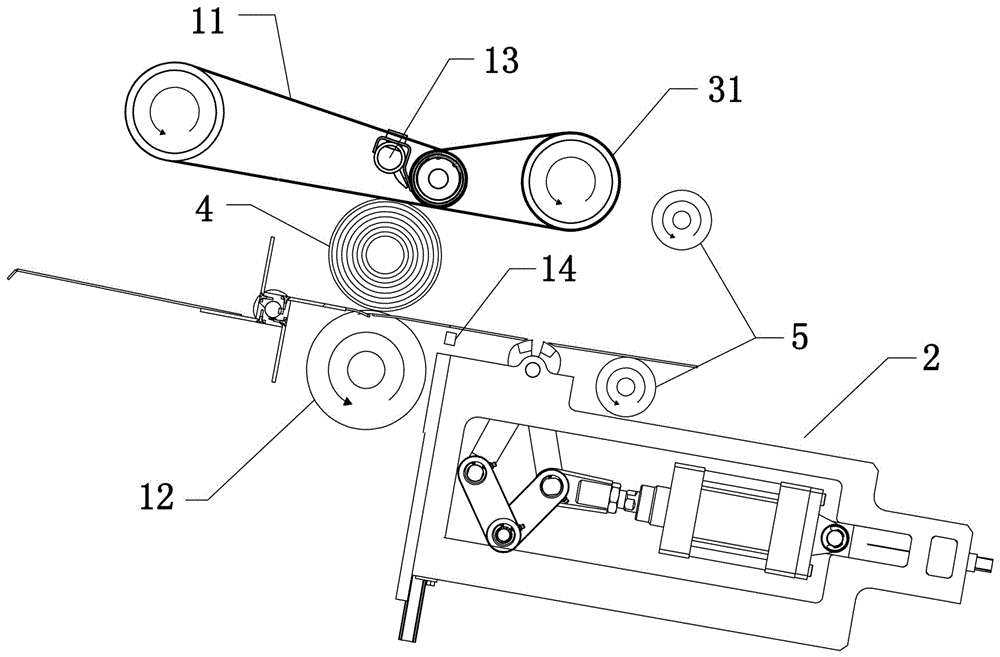

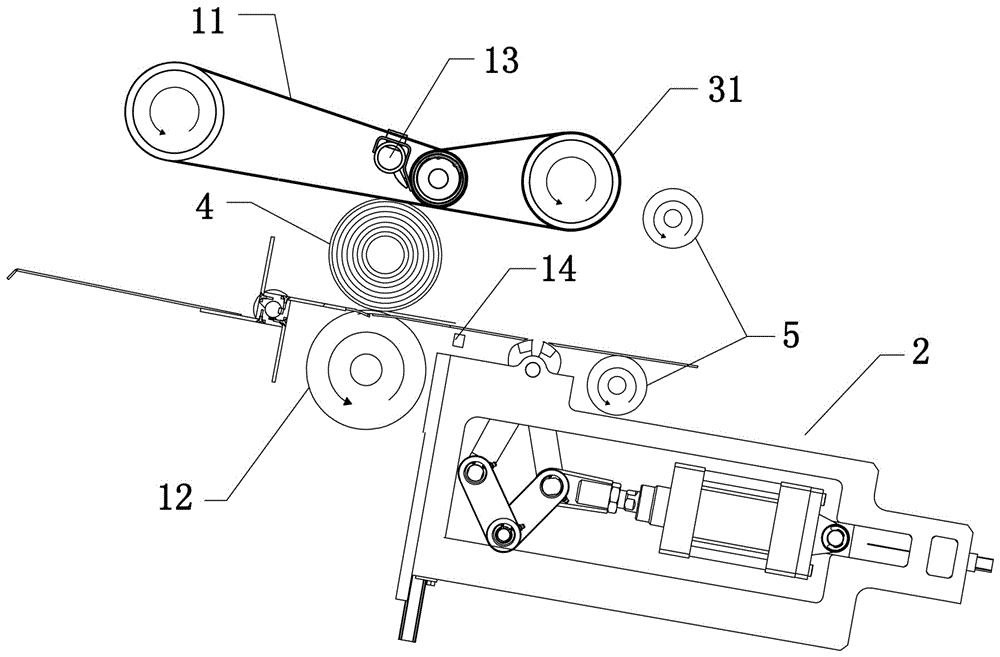

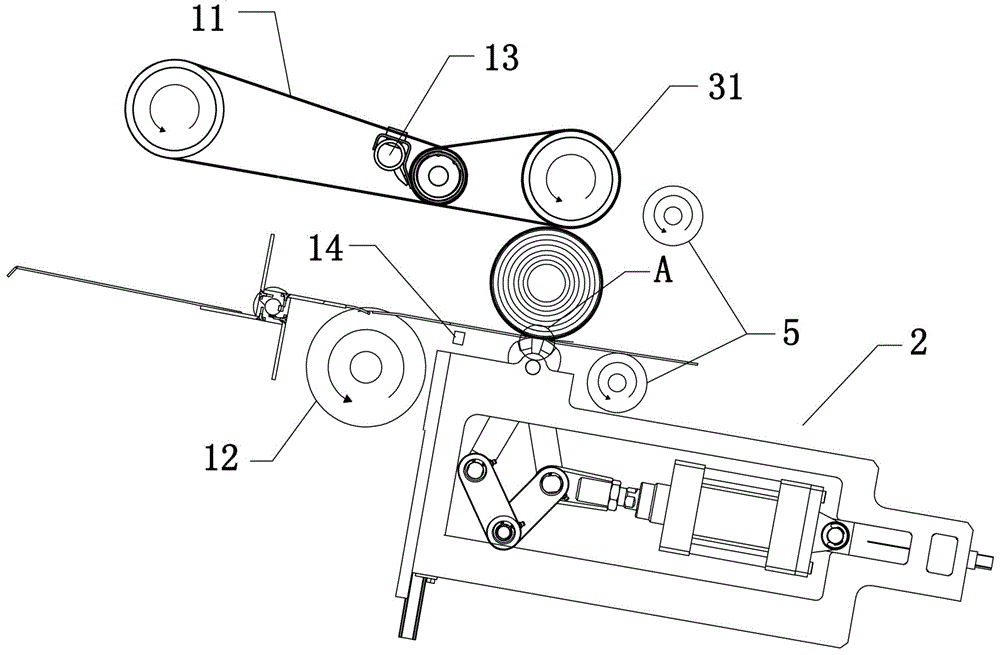

[0051] See attached figure 1 As shown, the reel glueless tail sealing device in this embodiment includes a tail-seeking mechanism for finding the tail end of the reel 4, a tail-sealing mechanism 2 located downstream of the paper-finding mechanism, and a tail-sealing mechanism 2 opposite to the tail-sealing mechanism 2 up and down. Squeezing device and finishing mechanism located downstream of tail sealing mechanism 2.

[0052] In this embodiment, the winding tail mechanism includes a conveying belt 11 , rollers 12 , air blowing pipe 13 and a detection head 14 . Wherein the conveyor belt 11 and the roller 12 are relatively up and down and rotate in the same direction, thereby forming a reel autorotation station that makes the reel 4 rotate in situ between the conveyor belt 11 and the roller 12. The very small speed difference rotates in the same direction, so that the linear speed of the reel 4 in the two rotation directions is basically the same, so that the reel 4 rotates al...

Embodiment 2

[0068] see Figure 19 As shown, the difference between the adhesive-free roll end sealing device in this embodiment and the first embodiment is that in this embodiment, the first clamping die 21a and the second clamping die 21b of the end sealing clip are arranged oppositely, and the driving unit 23 It is a telescopic cylinder and is respectively connected to push the first clamping mold 21a and the second clamping mold 21b on both sides, and the telescopic cylinders on both sides are synchronously stretched to drive the first clamping mold 21a and the second clamping mold 21b to open and close synchronously; in this implementation In the example, the extruding device includes a pressing plate 32 directly above the openings of the first clamping die 21a and the second clamping die 21b and an extruding cylinder 33 connected to the pressing plate 32 for driving the pressing plate 32 to press down. 4 for extrusion.

[0069] The working mode of the reel glueless tail sealing devi...

Embodiment 3

[0076] See attached Figure 27 As shown, the difference between the roll glue-free tail sealing device in this embodiment and Embodiment 1 is that in this embodiment, the first clamping mold 21a and the second clamping mold 21b are arranged oppositely, and the drive units 23 are located on both sides respectively. The first clamping mold 21a and the second clamping mold 21b are connected and pushed, and the two drive units 23 are synchronously expanded and contracted to drive the first clamping mold 21a and the second clamping mold 21b to open and close synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com