Production method of expanded polyethylene/polystyrene beads

A technology for foaming polyethylene and polystyrene particles, applied in the field of foaming materials, can solve problems such as weak mechanical rigidity of materials, and achieve the effects of improving production efficiency, high production efficiency and foaming ratio, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

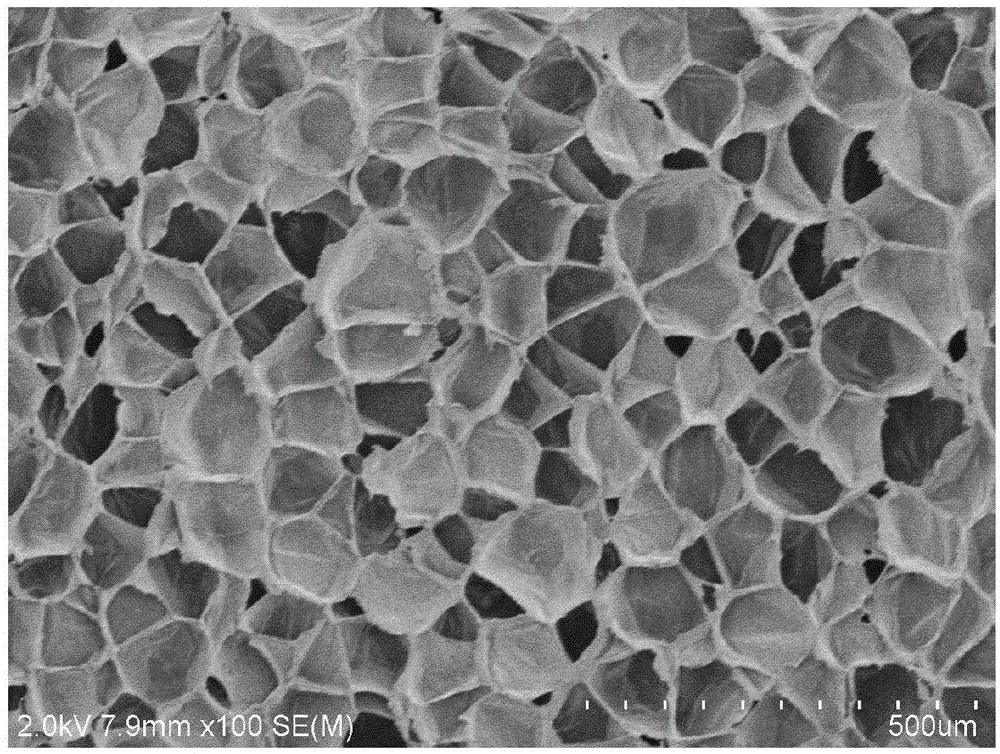

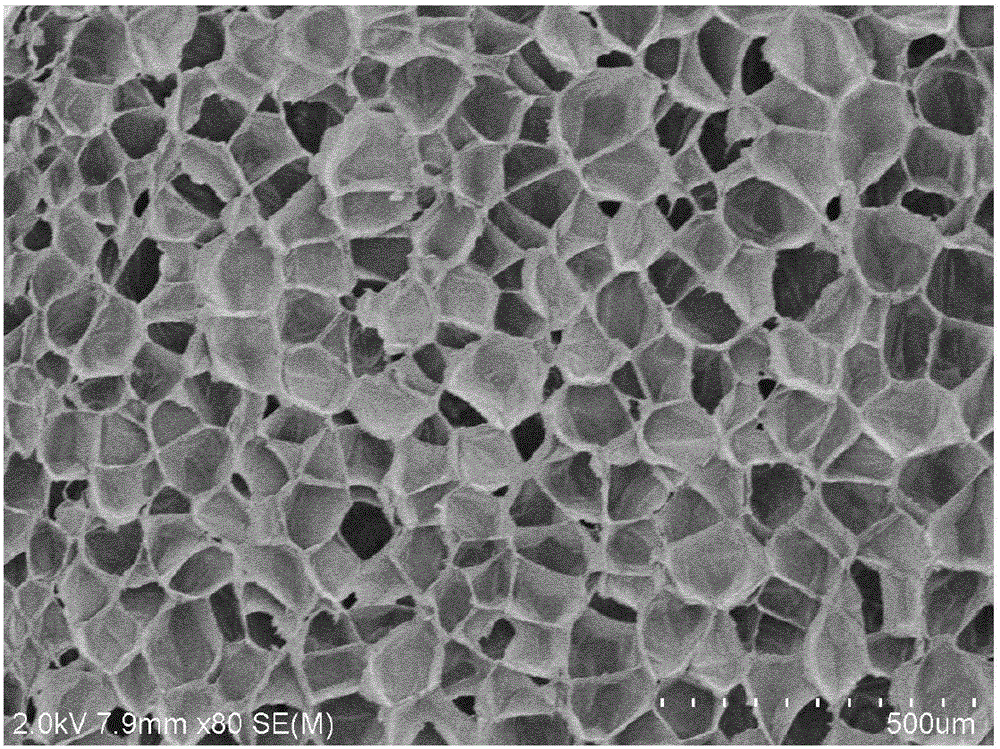

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

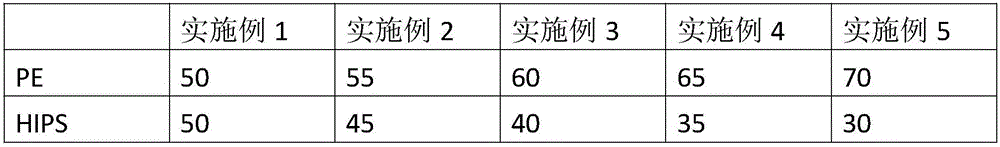

[0024] Table one is the batch list of main material (listed in the table as parts by weight)

[0025]

[0026]

[0027] Table two is a list of auxiliary ingredients (listed as parts by weight in the table)

[0028]

[0029] Dispersants can be selected from kaolin, calcium phosphate, etc., defoamers can be selected from silane defoamers, surfactants can be selected from calcium stearate, sodium dodecylbenzenesulfonate, cetyltrimethylammonium bromide Wait.

[0030] Table 3 Pressurization pressure and schedule

[0031]

[0032] The pressurization method adopts the injection of supercritical CO 2 , for gasification and pressurization. Under the same pressure, the uniformity of foamed polyethylene / polystyrene cells can be effectively controlled by adopting segmented pressure, and the expansion of foamed polyethylene / polystyrene can also be improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com