Special material for wind wheels of air conditioners and preparation method for special material

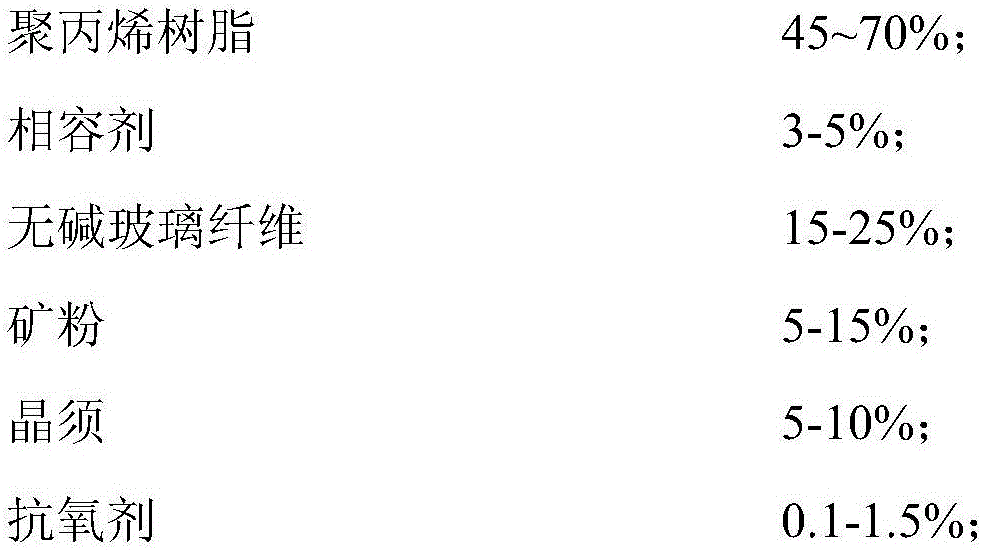

A technology for special materials and wind wheels, which is applied in the field of special materials for air-conditioning wind wheels and its preparation. It can solve the problems of high shrinkage rate and low impact strength of finished products, improve rigidity, improve dimensional stability, and reduce molding shrinkage rate and warpage. tendentious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

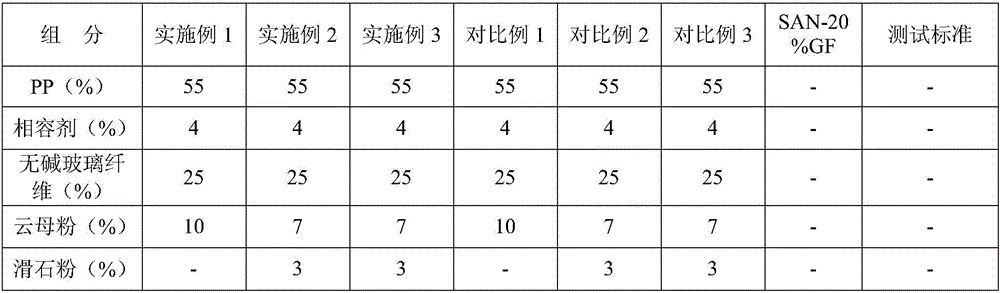

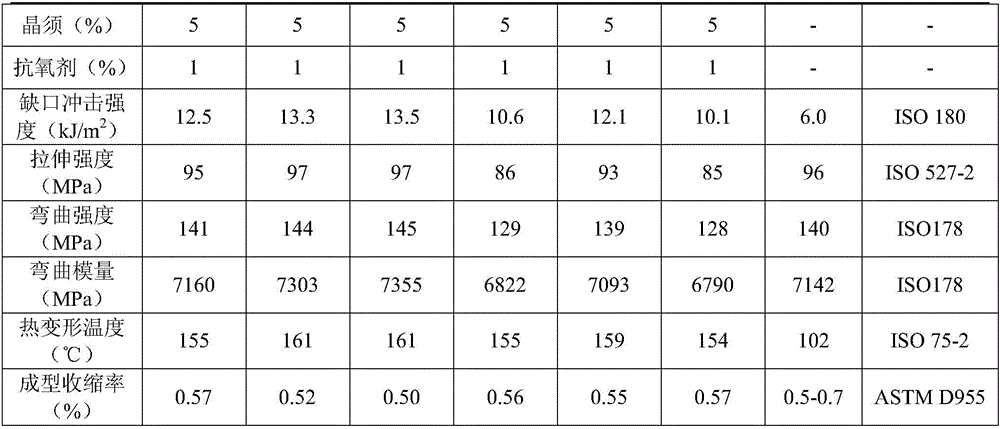

[0026] The raw material that present embodiment adopts and consumption see table 1, wherein:

[0027] The polyacrylic resin is a high-crystalline homopolypropylene, which comes from LOTTE Company, and its brand name is PP JSS-370N.

[0028] The compatibilizer is PP grafted maleic anhydride, which comes from Arkema Company, and the brand name is CA100.

[0029] Alkali-free glass fiber comes from OWENS CORNING company.

[0030] The mineral powder is 1250 mesh mica powder.

[0031] The whiskers are calcium sulfate whiskers modified by silane coupling agent.

[0032] The antioxidants are 1010 and 168.

[0033] The preparation method of special material for air-conditioning wind wheel is as follows:

[0034] After mixing polypropylene, compatibilizer, mineral powder, whiskers, antioxidant, etc. evenly, put them into the main feeding port of the twin-screw extruder, and put the alkali-free glass fiber into the side feeding port, and adopt the weak shearing process to carry out ...

Embodiment 2

[0036] See Table 1 for the raw materials and consumption used in this embodiment, and the raw materials other than mineral powder are all the same as in Example 1.

[0037] In this example, the mineral powder is a mixture of 1250 mesh mica powder and 5000 mesh talc powder in a mass ratio of 7:3.

[0038] In this example, the preparation method of the special material for the air-conditioning wind wheel is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0040] See Table 1 for the raw materials and consumption used in this embodiment, and the raw materials other than mineral powder are all the same as in Example 1.

[0041] In this example, the mineral powder is a mixture of 1250 mesh mica powder and 10000 mesh talc powder in a mass ratio of 7:3.

[0042] In this example, the preparation method of the special material for the air-conditioning wind wheel is the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com