A kind of preparation method of magnetic fluorescent composite material

A composite material and fluorescent technology, which is applied in the direction of luminescent materials, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of unsatisfactory magnetic and fluorescent properties of nanoparticles, and achieve good optical properties. Catalytic degradation, high yield, and good fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

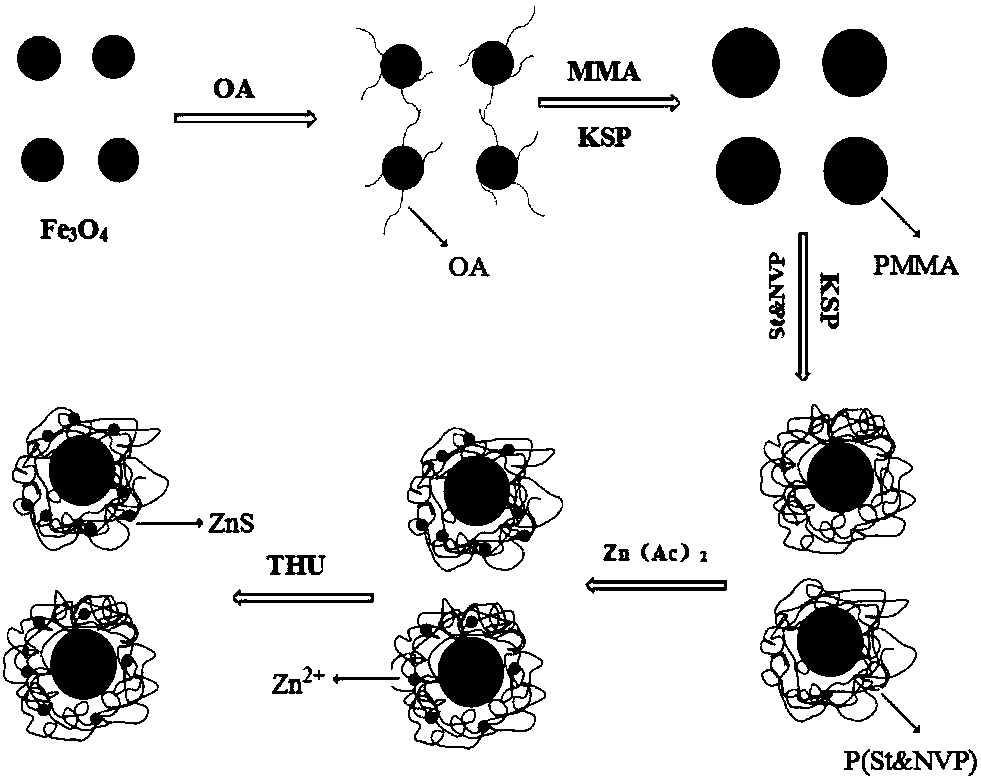

[0035] (1) The preparation method is as follows:

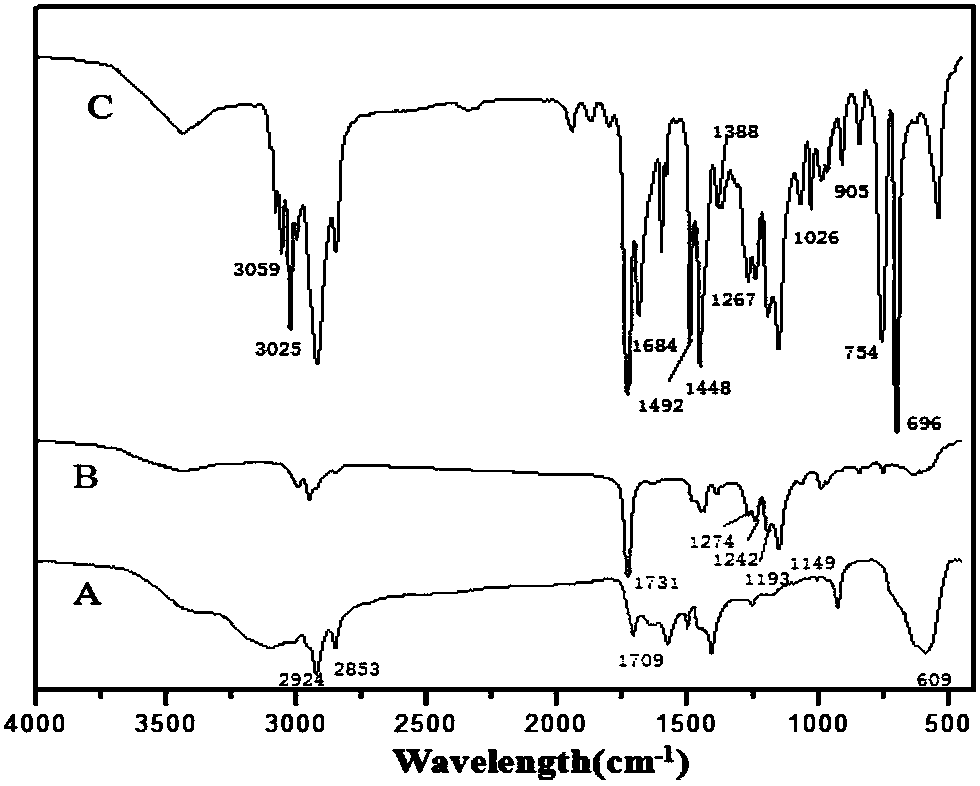

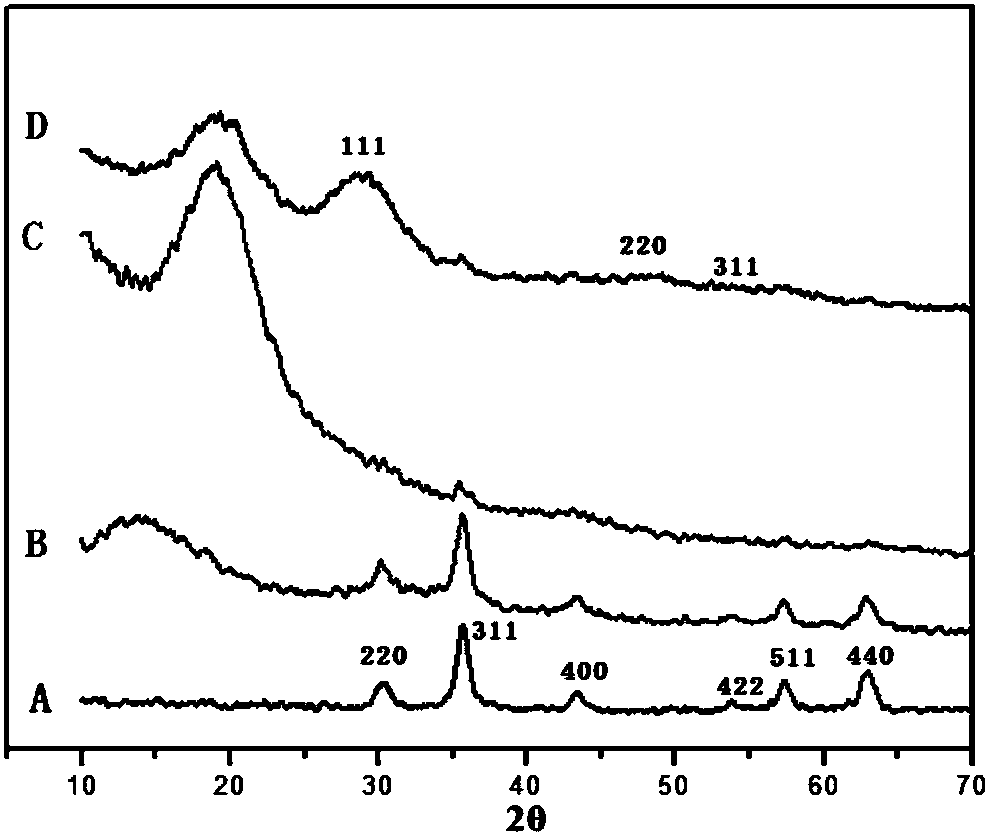

[0036] 1. Weigh 4.06g FeCl 3 ·6H 2 O and 2.78 g FeCl 2 4H 2 O dissolved in deionized water, N 2 Protect, heat up to 80°C with mechanical stirring, add 5 mL of acetone dissolved in oleic acid (oleic acid: acetone = 0.1 g: 5 mL), then add concentrated ammonia water dropwise, adjust the pH to 10-12, react for 30 minutes, and cool to room temperature. In the product, the hydrochloric acid solution of 2mol / L is added dropwise to obtain precipitate, and precipitate is washed with acetone, and then precipitate is redispersed in the dilute ammonia solution 35mL that contains a small amount of oleic acid (oleic acid: 9% ammoniacal liquor=1.0g: 35mL ), at N 2 Under protection, stir and heat to 80°C, and continue the reaction for 30min to obtain Fe 3 o 4 ferrofluid, the resulting Fe 3 o 4 Ferrofluid in N 2 Store under protection for later use.

[0037] 2. Add 5mL methyl methacrylate (MMA) and 100mL deionized water into a four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com