PC/ABS free-spraying resin composition improving silver wire problem in injection molding and preparation method of PC/ABS free-spraying resin composition

A resin composition and spray-free technology, which is applied in the field of PC/ABS spray-free resin composition and its preparation to improve the problem of injection molding silver wire, can solve the problems of different environmental pH, cannot be used at the same time, cannot be used in large quantities, etc., to achieve High molecular weight, reducing the possibility of substrate degradation, and solving the effect of material degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~2

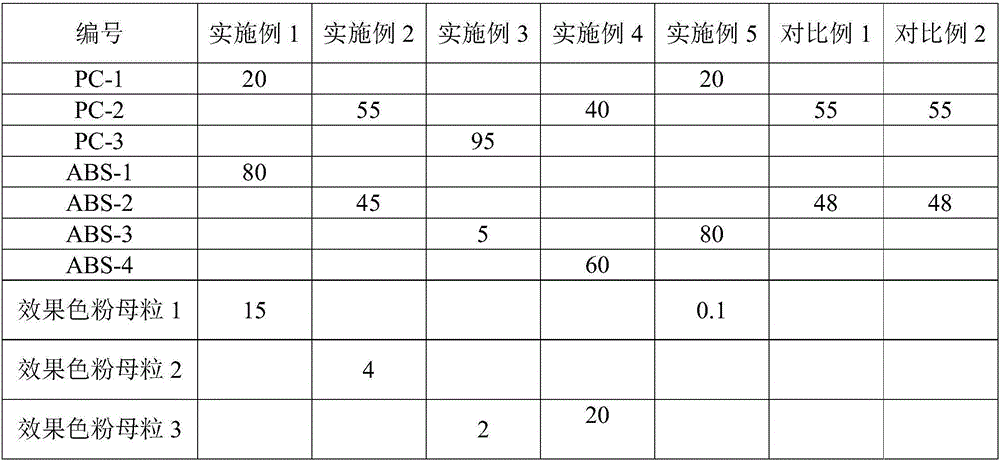

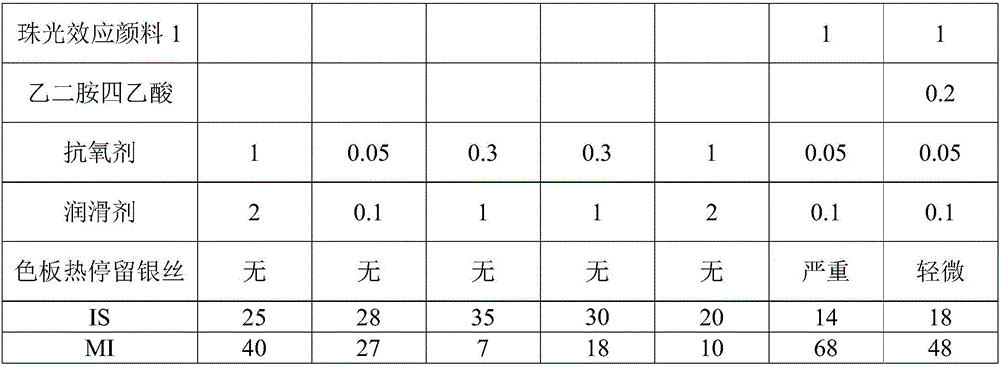

[0027] The components and contents used in each embodiment and comparative example are shown in Table 1, and the materials are prepared according to the components and contents of each embodiment and comparative example in Table 1 respectively.

[0028] First prepare the special-effect toner masterbatch: pre-mix the other raw materials except the above-mentioned masterbatch except the pearl effect pigment in the mixer, and then extrude the pre-mixed material through the twin-screw extruder, and at the same time, pass the side-feeding method. The pearlescent effect pigment is added into the melt according to the ratio, and extruded to obtain the special-effect toner masterbatch. Wherein the temperature of the extruder used is 190-230° C., the length-to-diameter ratio of the screw is 25-45, and the screw speed is 400-600 rpm.

[0029]Then according to the ratio in Table 1, the PC / ABS spray-free resin composition raw material does not contain the mixture of the effect toner maste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com