Use process of non-tonic surface active agent in ruminant production

A non-ionic surface and ruminant technology, which is applied in the application process field of NIS to improve the utilization efficiency of straw feed, can solve the problems of limited influence of fermentation, and achieve the effects of improving the degree of fermentation, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of application technique of NIS on ruminant production, its steps are:

[0022] (1) Dry the corn stalks, rice straw and wheat stalks after harvesting seeds at 60 or 62 or 65 or 67 or 70°C for 30 or 32 or 34 or 36 or 38 or 40 hours, and then crush them to 45 or 48 Or 50 or 53 or 55 mesh.

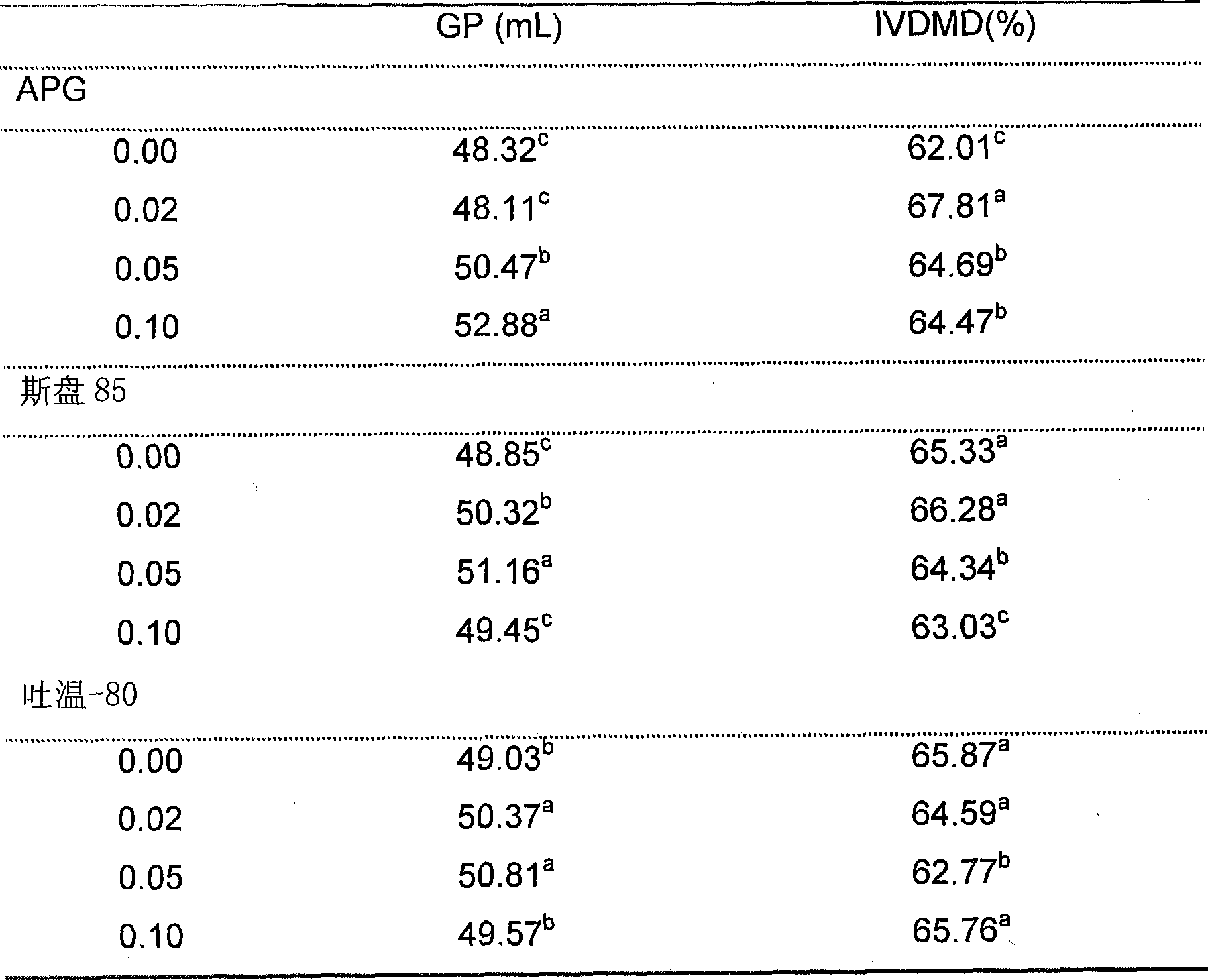

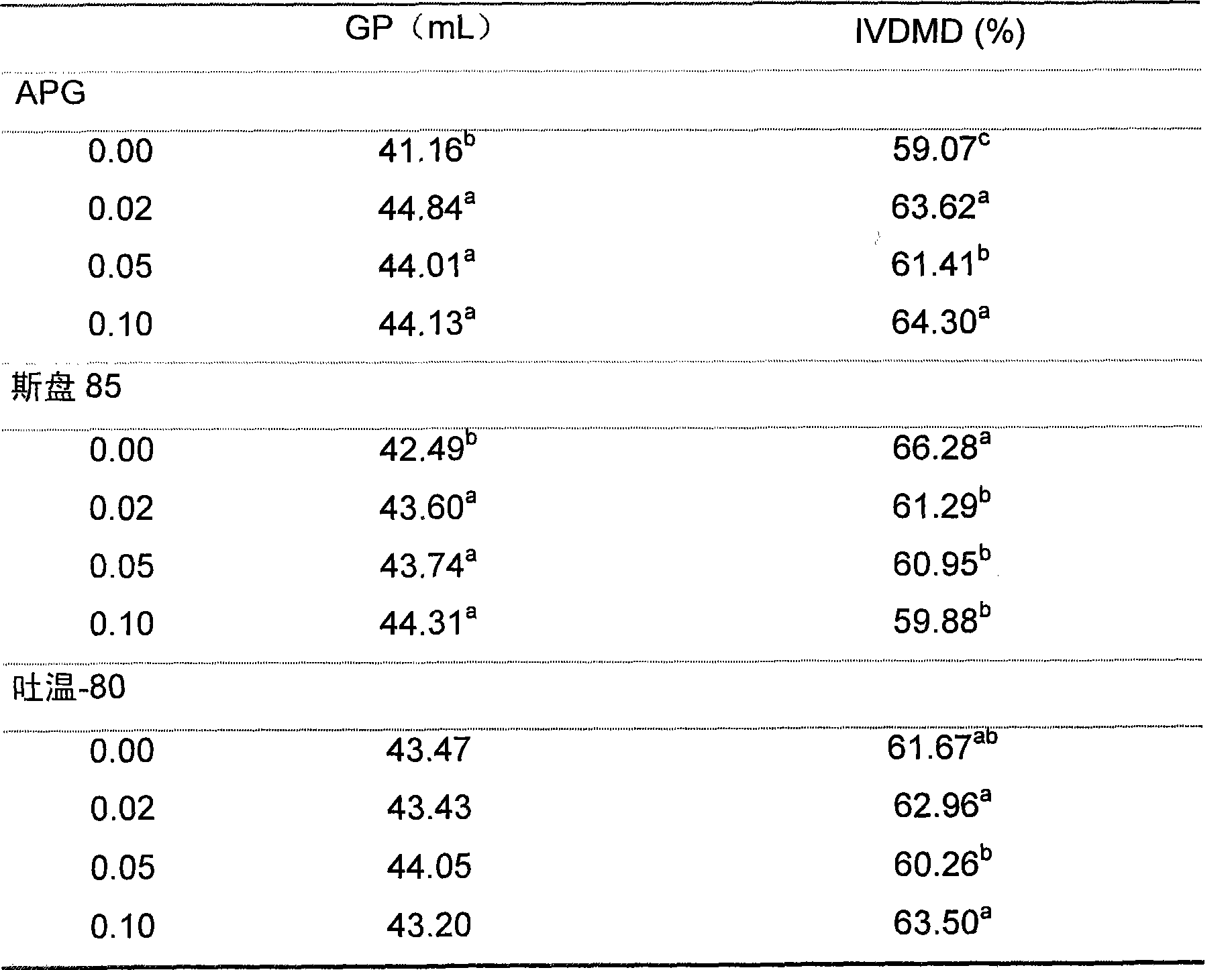

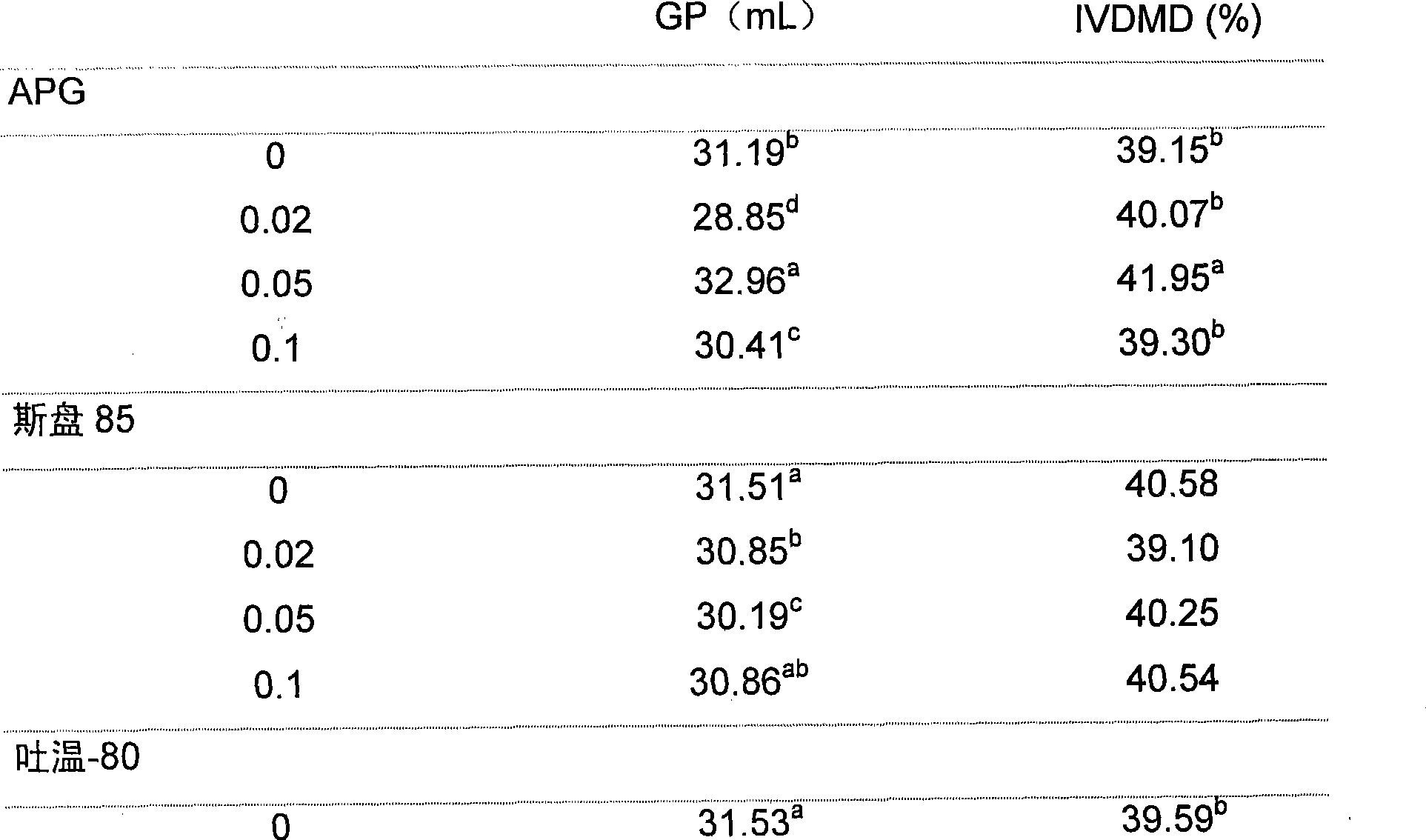

[0023] (2) APG was added to the pulverized corn stalks, rice straw and wheat stalks respectively, the APG addition levels were 0.00%, 0.02%, 0.05% and 0.10%, respectively, and three repetitions were set for each addition level.

[0024] (3) The in vitro fermentation process (Tang et al., 2006) was used to measure the gas production (GP) and in vitro dry matter degradation rate (IVDMD) of each treatment.

[0025] (4), according to the in vitro fermentation characteristics of each treatment, evaluate the appropriate addition amount of different types of roughage APG, the specific method is as follows:

[0026] When NIS chooses to use APG, when the roughage is corn stalks, the am...

Embodiment 2

[0028] A kind of application technique of NIS on ruminant production, its steps are:

[0029] (1) Dry the corn stalks, rice straw and wheat stalks after harvesting seeds at 60 or 62 or 65 or 67 or 70°C for 30 or 32 or 34 or 36 or 38 or 40 hours, and then crush them to 45 or 48 Or 50 or 53 or 55 mesh.

[0030] (2) Span 85 was added to crushed corn stalks, rice straw and wheat stalks respectively, and the addition levels of Span 85 were 0.00%, 0.02%, 0.05% and 0.10%, respectively, and three repetitions were set for each addition level.

[0031] (3) The in vitro fermentation process (Tang et al., 2006) was used to measure the gas production (GP) and in vitro dry matter degradation rate (IVDMD) of each treatment.

[0032] (4), according to the in vitro fermentation characteristics of each treatment, evaluate the appropriate addition amount of Span 85 for different types of roughage, the specific method is as follows:

[0033] When NIS chooses to use Span 85 and the roughage is c...

Embodiment 3

[0034] A kind of application technique of NIS on ruminant production, its steps are:

[0035] (1) Dry the corn stalks, rice straw and wheat stalks after harvesting seeds at 60 or 62 or 65 or 67 or 70°C for 30 or 32 or 34 or 36 or 38 or 40 hours, and then crush them to 45 or 48 Or 50 or 53 or 55 mesh.

[0036] (2), pulverized corn stalks, rice straw and wheat stalks are added with Tween-80 respectively, the addition levels of Tween-80 are respectively 0.00%, 0.02%, 0.05% and 0.10%, and each addition level is established three times .

[0037] (3) The in vitro fermentation process (Tang et al., 2006) was used to measure the gas production (GP) and in vitro dry matter degradation rate (IVDMD) of each treatment.

[0038] (4), according to the in vitro fermentation characteristics of each treatment, evaluate the appropriate addition amount of different types of roughage Tween-80, the specific method is as follows:

[0039] When NIS chooses to use Tween-80 and the roughage is cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com