Sesame oil processing and refining device

A refining device and sesame oil technology, which is applied in the oil field, can solve the problems of difficult colloidal separation, low work efficiency, and long processing time, and achieve the effects of improving production flow, increasing production efficiency, and improving oil purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

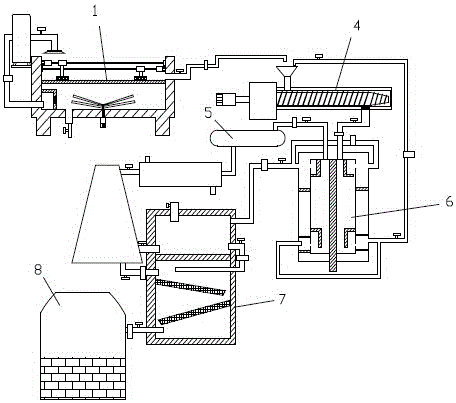

[0039] like figure 1 As shown, this embodiment discloses a sesame oil processing and refining device, which includes a sedimentation layered water treatment sesame picking mechanism 1, a sesame oil pressing mechanism 4, a hot water tank 5, and a centrifugal separation of sesame oil according to the process flow. Mechanism 6, sesame oil filter mechanism 7, sesame oil discharge tank 8. The hot water tank 5 is used for pouring hot water into the crude sesame oil after oil extraction, and the crude sesame oil centrifugal separation mechanism 6 is used for solid-liquid separation of the crude sesame oil after oil-water mixing. The oil filter mechanism is used to filter the sesame oil through the sesame crude oil centrifugal separation mechanism 6 . Sesame oil discharge tank 8 is in order to store the sesame oil that filters.

[0040] like Figure 2-3 As shown, the sedimentation layered water treatment sesame picking mechanism 1 includes a pool 11 , a material separation net 12 , a...

Embodiment 2

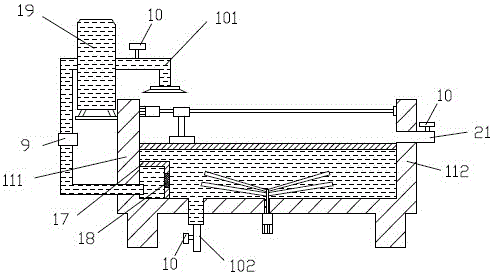

[0057] like Figure 2-4 As shown, the difference between this embodiment and the above-mentioned embodiments is that a stirring device is provided in the water storage chamber of the pool 11 . The stirring device includes a stirring motor 141 and a stirring paddle 142 . The output end of the stirring motor 141 is connected with the stirring paddle 142 .

[0058] By starting the stirring motor 141, the stirring paddle 142 is driven to rotate in the pool 11, which drives the rotation of the water in the pool 11, and drives the rotation of the sesame located above the material separation net 12, so that the sludge in the sesame is quickly cleaned out and the cleaning efficiency is improved. .

[0059] In some embodiments: the bottom of the pool 11 is provided with a motor shaft insertion port, and a waterproof bearing 15 is provided in the motor shaft insertion port. The fixed end of the stirring motor 141 is arranged at the bottom of the pool 11 , and the output end of the st...

Embodiment 3

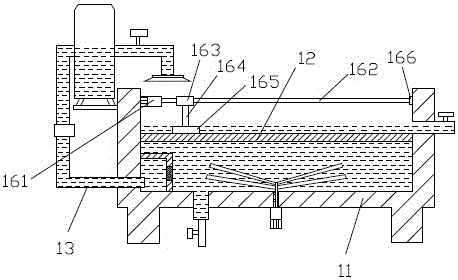

[0062] like figure 2 , 3 As shown, the difference between this embodiment and the above-mentioned embodiments is that the pushing mechanism includes a pushing motor 161 , a screw rod 162 , a slider 163 , a connecting rod 164 , and a pushing plate 165 . The water storage cavity of the pool 11 includes a first side wall 111 and a second side wall 112 which are oppositely arranged. The outlet is located on the first side wall 111 of the water storage cavity. The fixed end of the pusher motor 161 is arranged on the second side wall 112 of the water storage cavity and is positioned above the material separating net 12, the output end of the fixed end of the pusher motor 161 is connected with an end of the screw mandrel 162, and the end of the screw mandrel 162 The other end is rotatably connected to the second side wall 112 through a bearing 166 . The slider 163 is threadedly engaged with the screw rod 162 , and the bottom of the push plate 165 is close to or in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com