Quick support system of high-rise steel structure house composite floor slab

A technology of superimposed floor slabs and support systems, applied to floors, building components, building structures, etc., can solve problems such as high construction costs, slow construction progress, and high safety risks, and achieve space saving, construction speed, and increase in size. The effect of a single span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

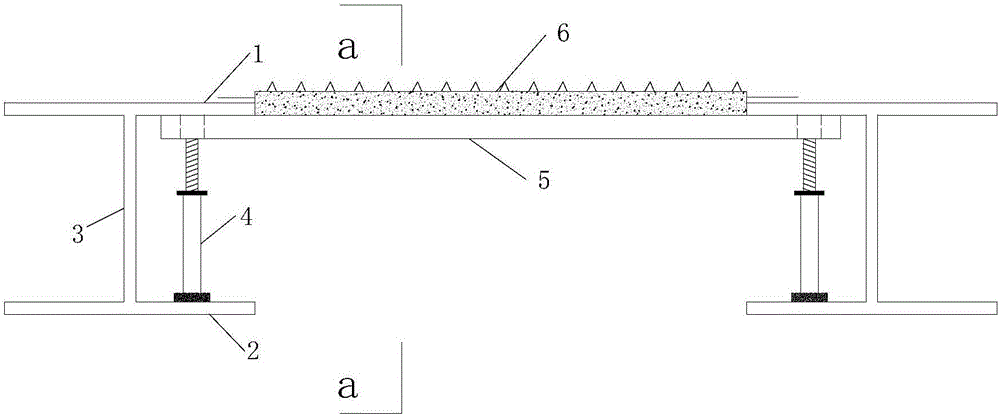

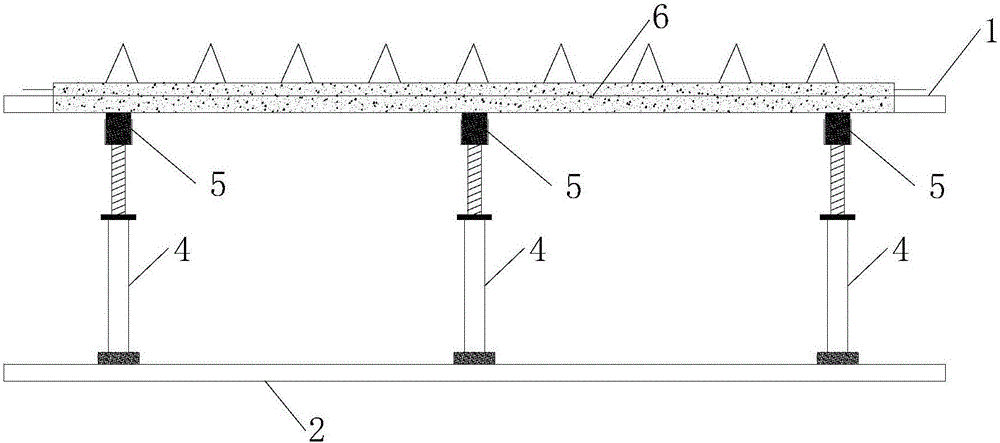

[0019] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0020] Referring to the accompanying drawings, the rapid support system for laminated floors of high-rise steel structure houses includes symmetrical H-shaped steel beams, support frames, and prefabricated panels. The H-shaped steel beams include upper plane 1 and lower plane 2, and connect upper plane 1 and The longitudinal surface 3 of the vertical direction of the lower plane 2; the support frame includes a height-adjustable U-shaped jack 4 and a crossbeam 5, and the adjustable height U-shaped jack 4 is placed on the lower plane 2, and the crossbeam 5 is placed on In the U-shaped groove of the height-adjustable U-shaped jacking 4 , the crossbeam 5 is pressed against the bottom surface of the upper plane 1 by adjusting the height of the U-shaped jacking 4 , and the prefabricated board 6 is flatly laid on the crossbeam 5 .

[0021] The crossbeam 5 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com