Desanding apparatus free of disassembly for washing

A disassembly-free and sand-separating technology, which is applied in the petrochemical field, can solve the problems of time-consuming, capital-intensive, and difficult, and achieve the effects of avoiding manual disassembly, prolonging the service life, and ensuring the quality of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

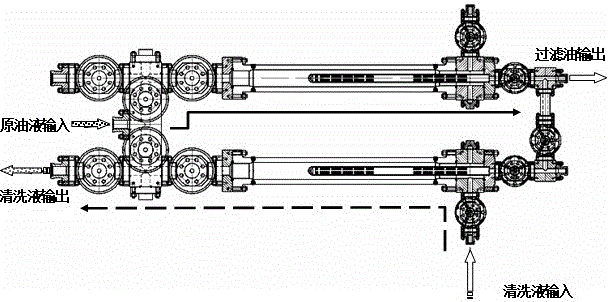

[0023] The present invention takes figure 1 The specific implementation method is described as the best embodiment:

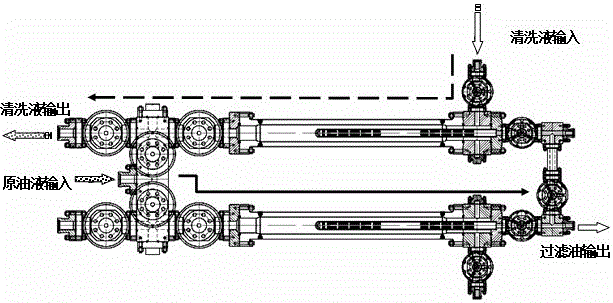

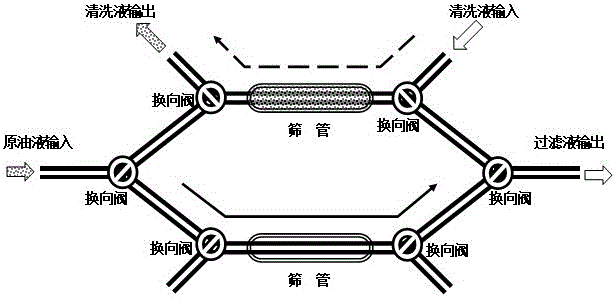

[0024] Due to the different components and diameters of sand and gravel in crude oil, after the long-distance transportation of pipelines, it often appears that the small diameter components are at the bottom and the coarse components are at the top. figure 2 It is a schematic diagram of the traditional technical structure; it is not difficult to see that a bypass shunt pipeline is installed in parallel (parallel connection) beside the filter pipeline, and the negative pressure extraction method of the core of the screen 15 is used for sand filtration, and the sand deposited at the bottom of the pipeline is carried out along with the pipeline. The punching of imported crude oil is continuously pushed to the front along the bottom of the pipeline, while the oil layer with lighter specific gravity is continuously sucked away by the screen tube 15 at the core, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com