Plateau high-gas extra long separating type tunnel construction ventilation method

A technology of tunnel construction and ventilation method, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve problems such as poor tunnel ventilation, achieve good ventilation, avoid waste of resources, and ensure personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] This embodiment is applied to the construction process of high-gassed long separated tunnels on the plateau after strong earthquakes.

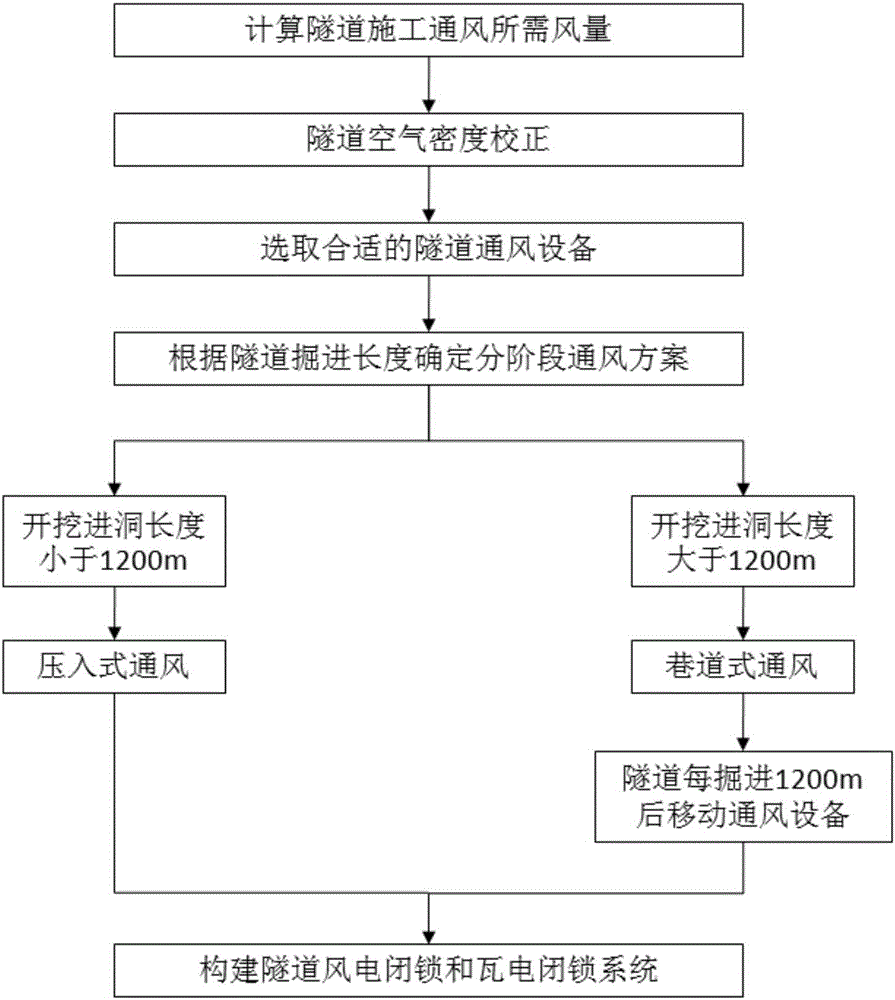

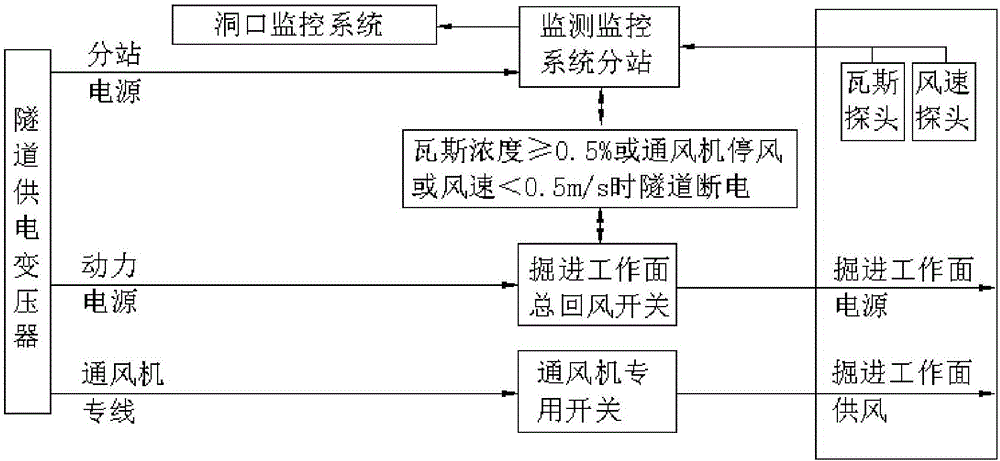

[0048] Such as figure 1 As shown, a ventilation method for plateau high gas long separation tunnel construction adopts the following steps:

[0049] Step a: According to the characteristics and construction length of the separated ultra-long tunnel on the plateau, as well as the distribution characteristics of the separated tunnel for pedestrians and vehicles, the ventilation calculation is performed. The air volume required for construction ventilation in a single separated tunnel is calculated separately according to the blasting smoke exhaust in the construction tunnel, the allowable minimum wind speed of the plateau gas tunnel in the tunnel, the amount of gas gushing out, the maximum number of people working in the tunnel at the same time, and the dilution of the internal combustion engine exhaust gas used in the tunnel. , and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com