Engine waste gas cycle purifying and silencing system

An exhaust gas circulation and engine technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of short service life of the system and poor exhaust gas purification effect, and achieve a simple structure, improved noise reduction effect, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

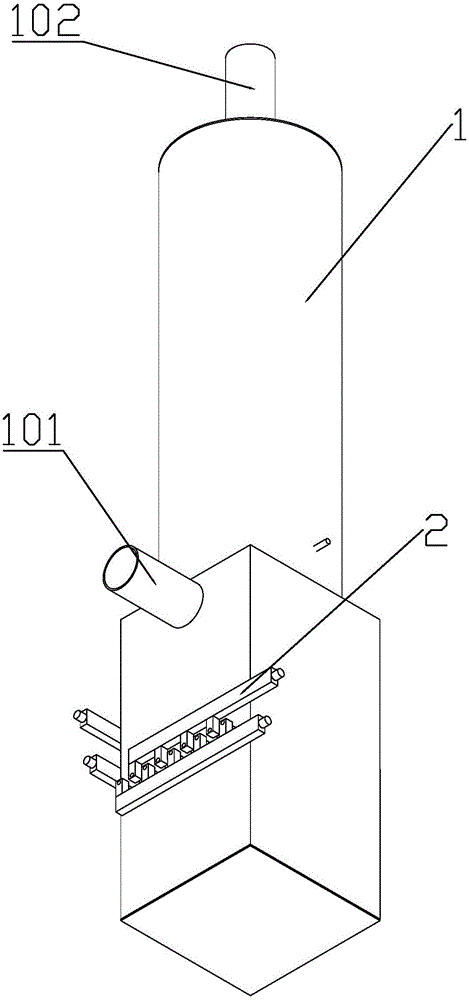

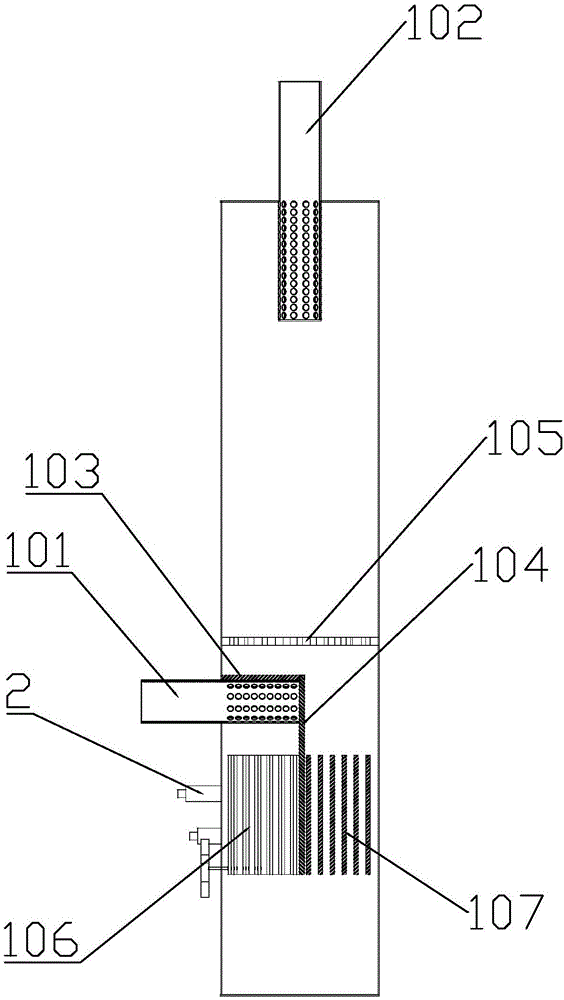

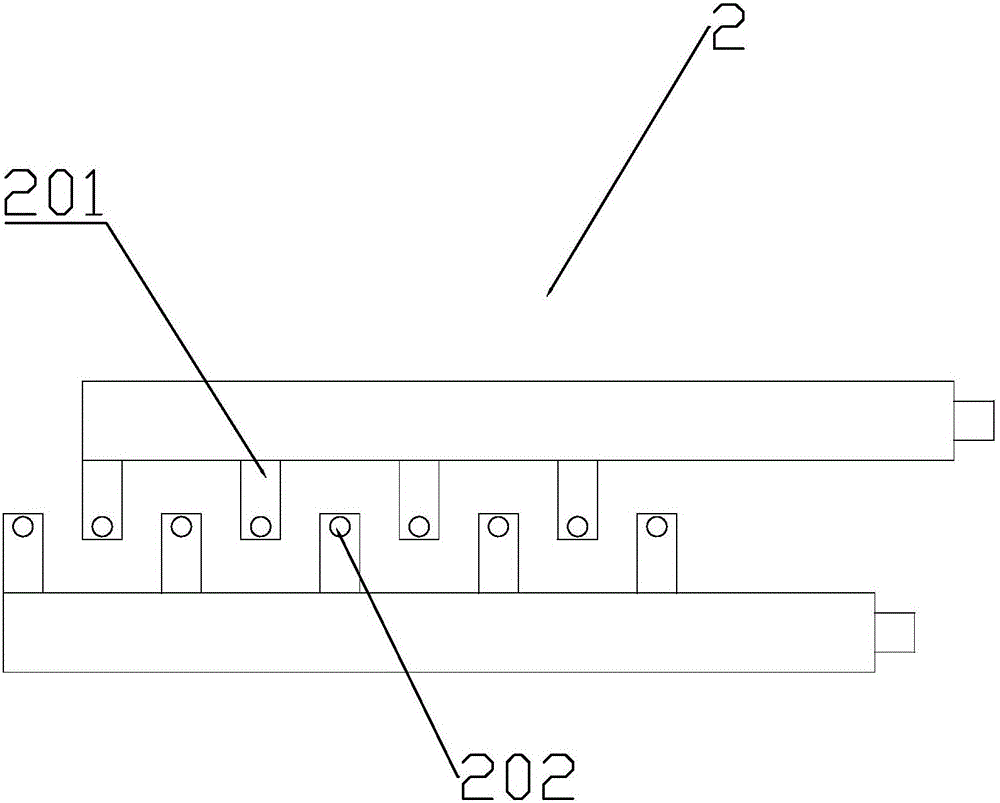

[0027] see figure 1 and figure 2 As shown, the present invention provides an engine exhaust gas circulation purification and muffler system, comprising a body 1 formed with a cavity inside and placed vertically, the side wall of the body 1 is provided with an air inlet communicating with the cavity, and the air inlet The air intake pipe 101 is connected at the top of the body 1, and the top of the body 1 is provided with an exhaust port communicating with the cavity. Two partitions 104; the first partition 103 is arranged horizontally above the air inlet, and the length of the first partition 103 is less than the inner diameter of the cavity; the second partition 104 is vertically arranged and connected with the end of the first partition 103 , the length of the second partition 104 is smaller than the distance between the first partition 103 and the bottom of the cavity. The second dividing plate 104 is provided with several vertically arranged electrode plates 106 between...

Embodiment 2

[0032] see Figure 8 to Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the inner wall of the cavity is located between the discharge electrode and the bottom of the exhaust pipe, and several baffles are provided. The baffles are divided into a through-hole area and a closed area, and the through-hole area The area of the baffle is 2 / 3 of the area of the baffle, and several through holes are opened in the through hole area. The closed area on the baffle adjacent to the discharge electrode corresponds to the position of the dust collecting plate, and the positions of the closed areas on two adjacent baffles are staggered from each other.

[0033] Since the exhaust gas passes through the staggered baffles in the closed area before being discharged, there are overlapping parts in the through hole area, so that the exhaust gas passing through the small hole does not directly change the direction and is discharged from the exhaust pipe, which gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com