An anti-coking biomass pellet burner

A technology of biomass pellets and burners, which is applied in the field of biomass burners and anti-coking biomass pellet burners, which can solve the problems of shortened equipment life and increased failure rate, reduce labor intensity, facilitate slag removal, and improve thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

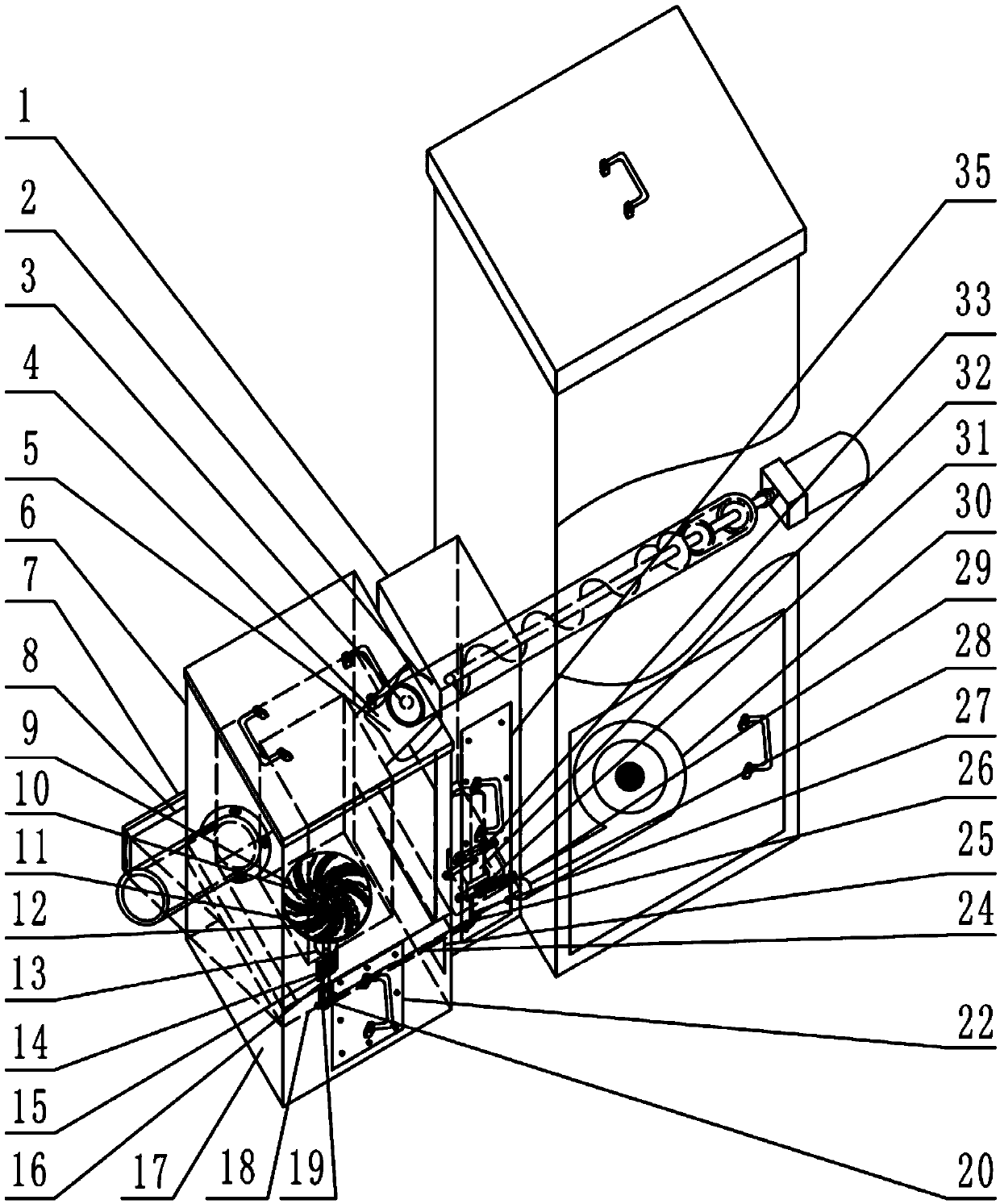

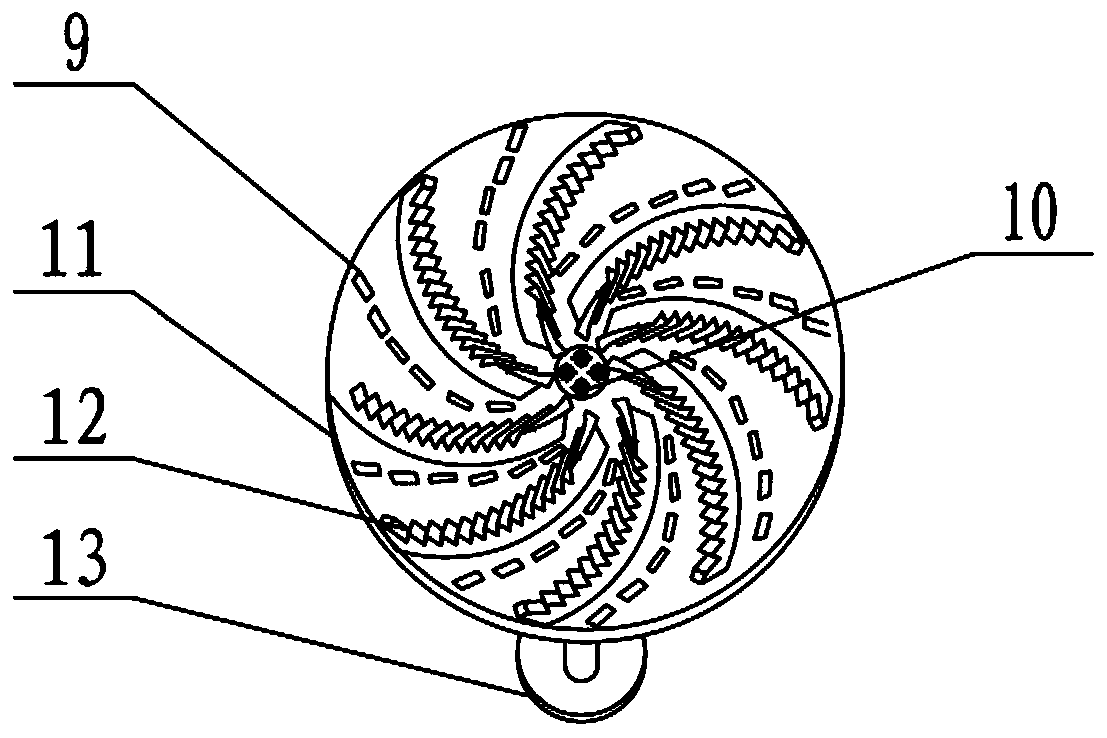

[0030] Such as figure 1 As shown, an anti-coking biomass pellet burner includes a burner body, an air bag 1 and a feeding mechanism. In the feeding mechanism, the feeding screw and the feeding screw feeding pipe pass through the air bag 1 and are connected to the furnace of the burner body. 1 combustion The furnace bridge 11 in the machine body is a circular furnace bridge. The front of the furnace bridge is welded with an arc-shaped sawtooth slag removal knife 12, which is connected to the furnace bridge rotation shaft 16 in the middle. Cyclone airflow hole 9. The burner is also equipped with an anti-temper mechanism. The anti-temper mechanism is passed through the anti-temper air inlet hole 2 of the feeding pipe, the punching air inlet hole 3 of the outer casing of the burner, the punching air inlet hole 5 of the blanking inclined plate, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com