Gas furnace head

A gas stove and stove base technology, which is applied in the field of gas stoves, can solve the problems of yellow flame phenomenon, insufficient combustion, and flame separation phenomenon of the flame, and achieves the effects of good flame stabilization effect, simple structure and optimized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

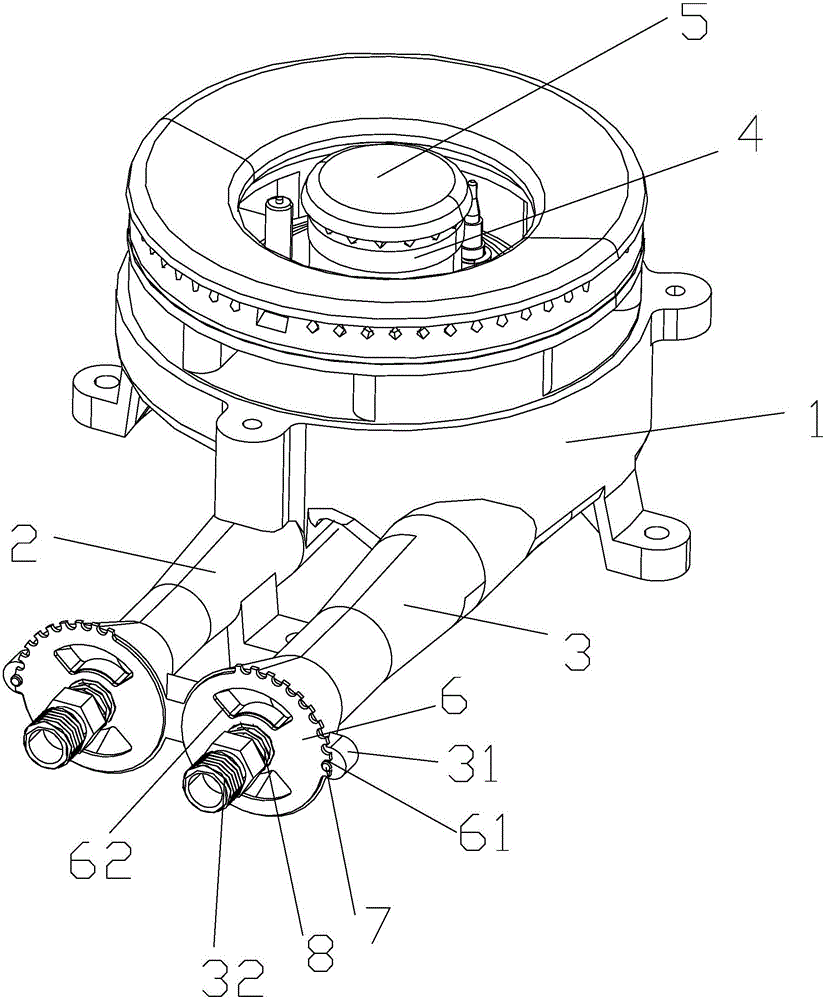

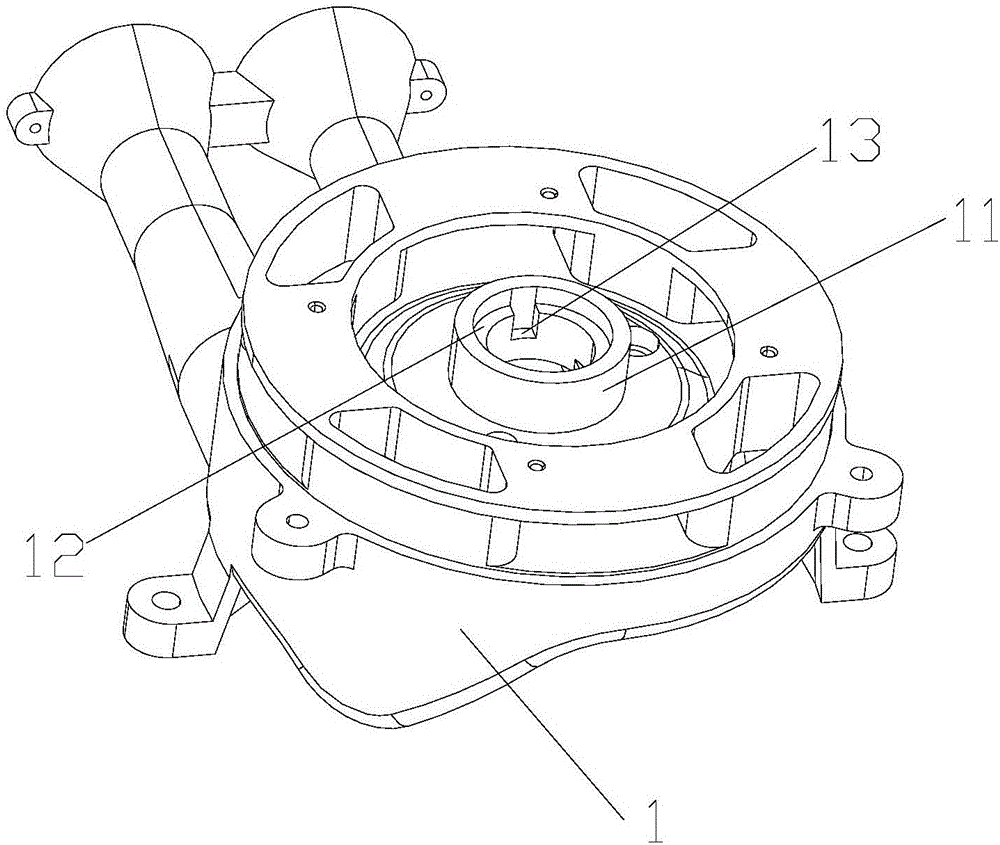

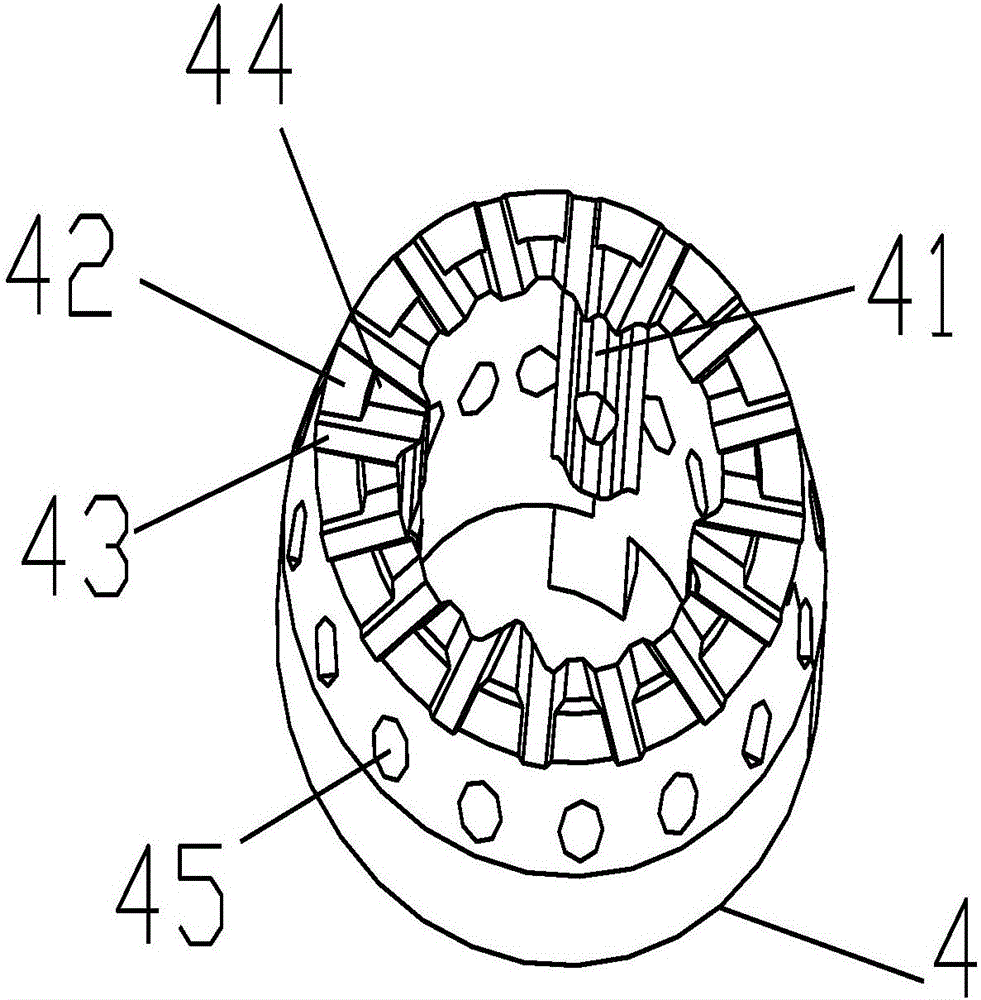

[0021] Such as Figure 1 to Figure 6 As shown, a gas burner includes a furnace base 1, a central air supply chamber and an outer air supply chamber arranged on the furnace base and isolated from each other, the central air supply chamber communicates with the first air intake pipe 2, and the outer air supply chamber communicates with the first The two air intake pipes 3 are connected, and the opening end of the central air supply chamber is provided with a first mounting seat, and the copper ring 4 is connected with the first mounting seat through a non-rotation mechanism; it also includes a disc-shaped flame-stabilizing cover 5, a flame-stabilizing The middle part of the inner side of the cover 5 is provided with a circular protrusion 51, which is embedded in the cavity of the copper ring 4 and positioned by means of the inwardly protruding bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com