Sleeve grouting compactness detection device and detection method

A technology of density detection and sleeve grouting, which is applied in the direction of testing the strength of materials using a single impact force, which can solve the problem of undetectable density of sleeve grouting, and achieve the effect of improving the technical level, ensuring seismic performance and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

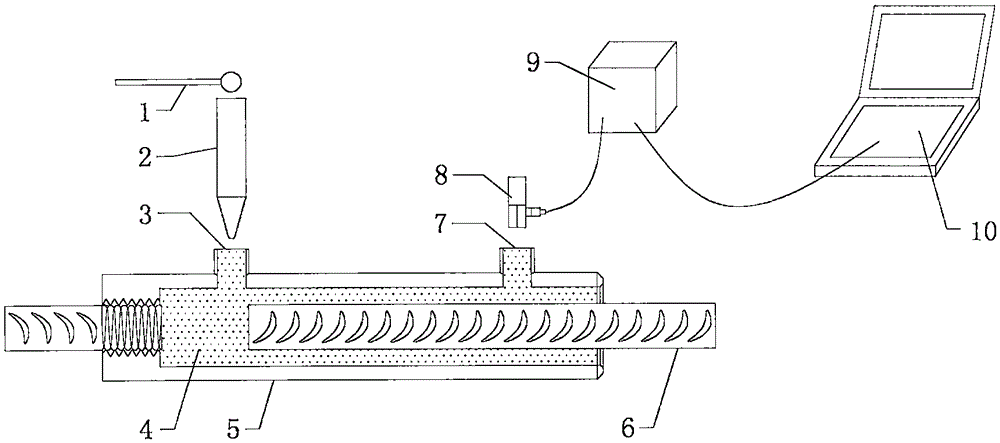

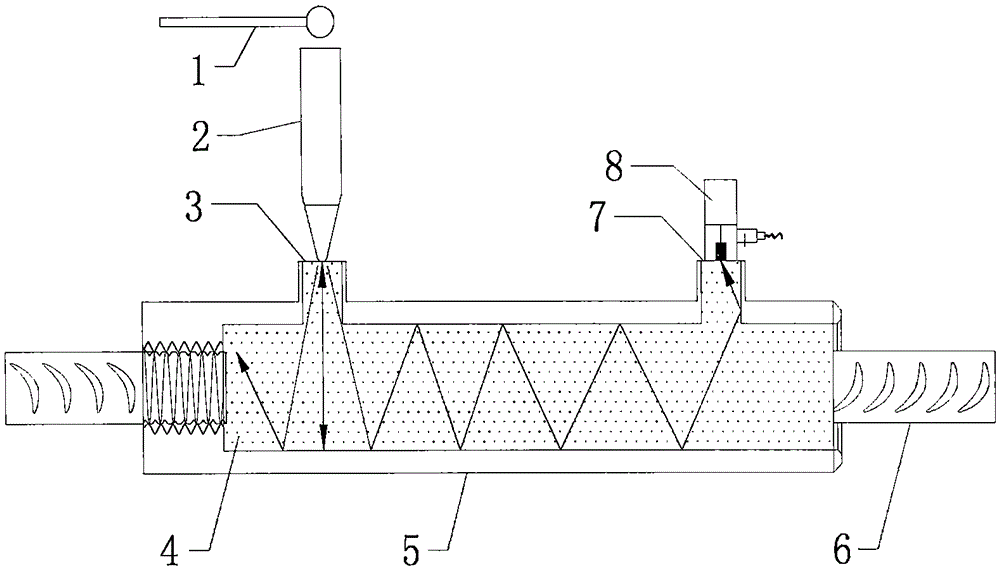

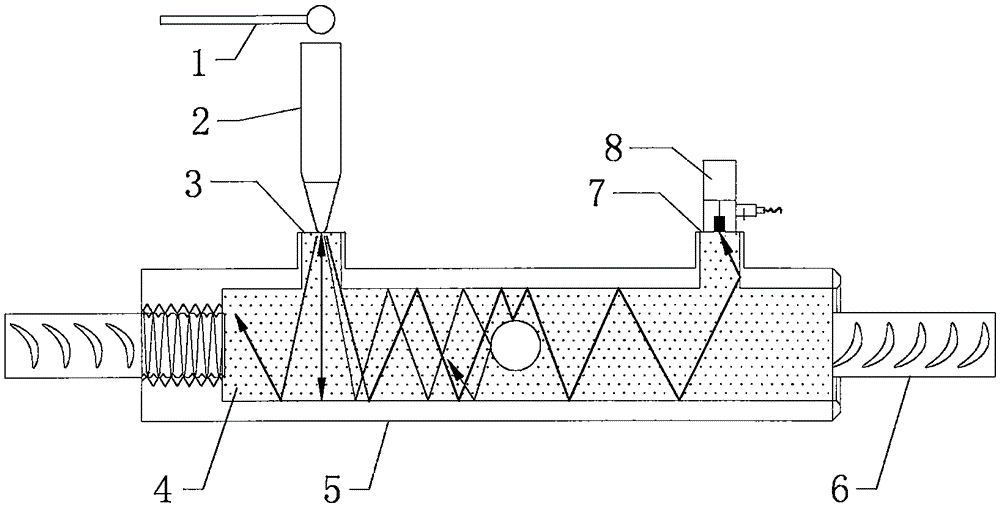

[0029] Such as figure 1 As shown, the present invention discloses a sleeve grouting compactness detection device, comprising an impact hammer 1, a guide 2, a grout outlet 3, a grout 4, a sleeve 5, a steel bar 6, a grout inlet 7, a sensor 8, a signal Amplifier 9, computer 10. The sleeve 5 is provided with a steel bar 6, and the steel bar 6 and the sleeve 5 are connected by grouting to form a sleeve slurry-anchor connector. The sleeve slurry-anchor connector can have various forms, which will not be described in this embodiment. The sleeve One end of 5 is connected to the steel bar, and the connection method includes threaded connection or other connection methods, but no matter what the connection method is, the stable connection between the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com