Microwave chip screening device and screening method therefor

A microwave chip and screening device technology, which is applied in the direction of measuring devices, measuring device shells, and electronic circuit testing, can solve the problems of increased equipment cost, waste, and small force, and achieve good versatility, reduced scrapping, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below.

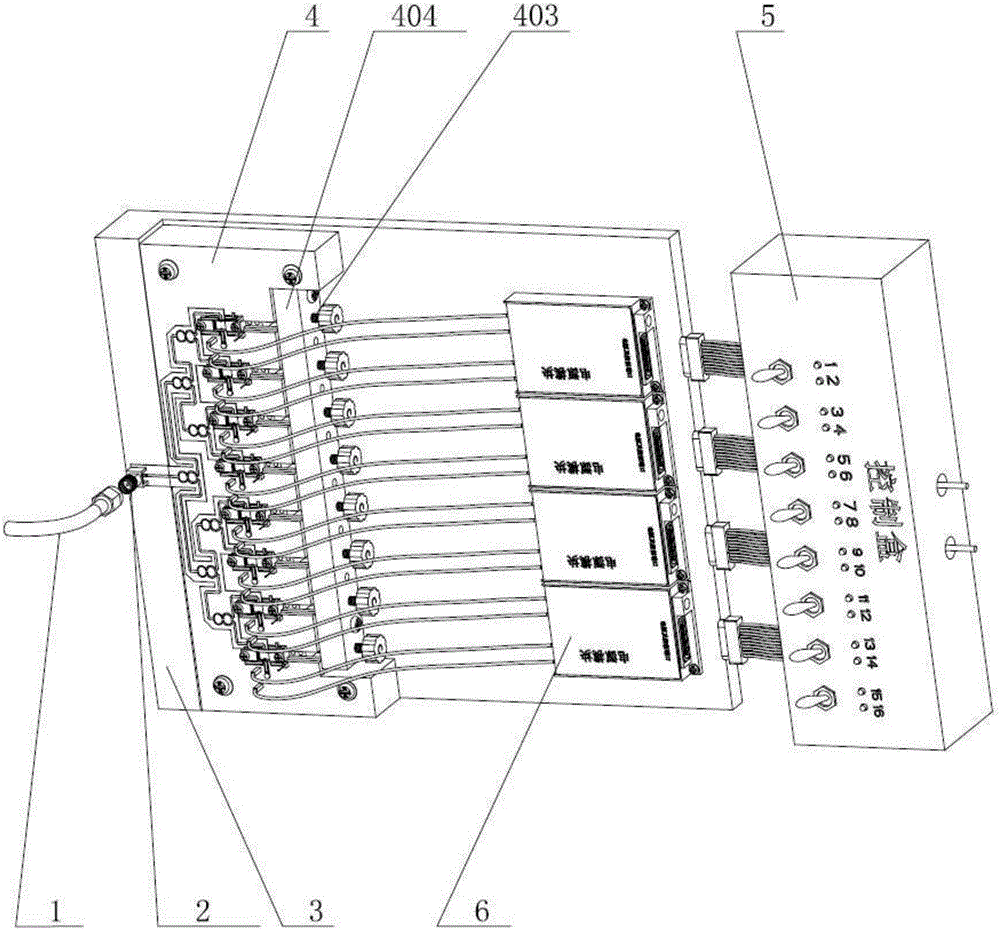

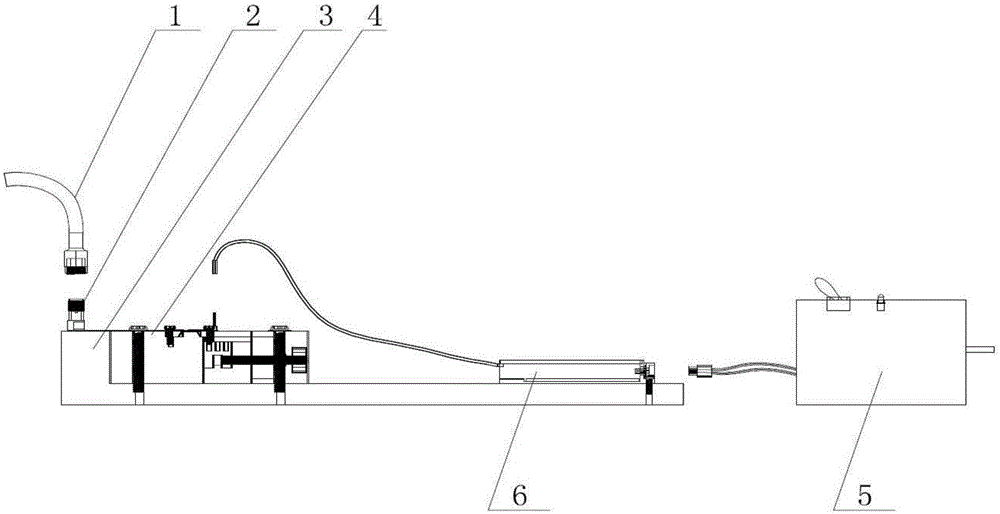

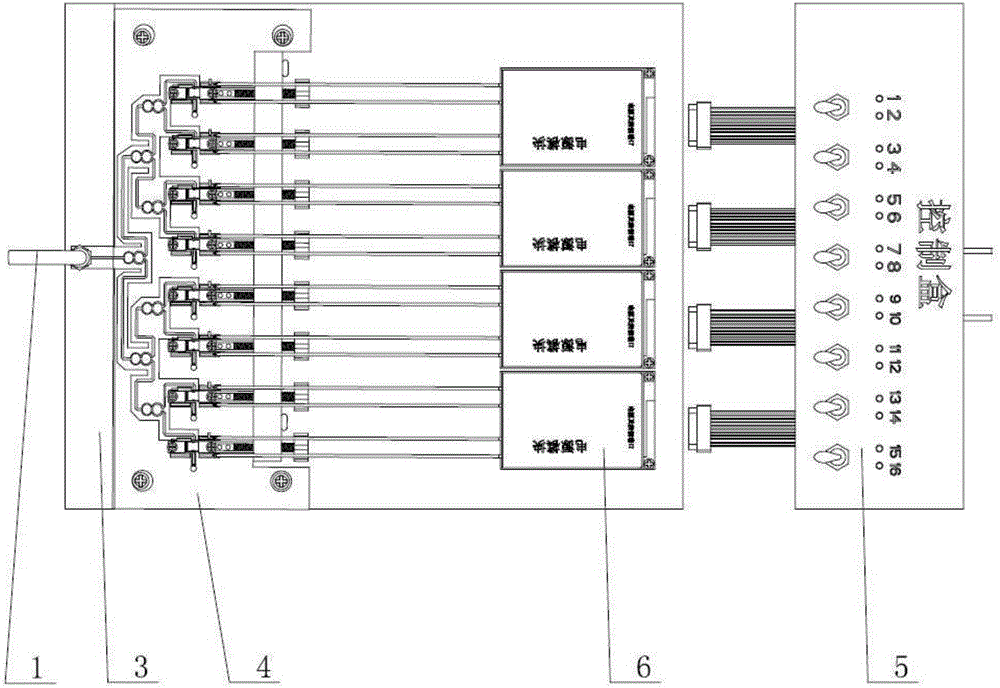

[0034] Such as figure 1 , figure 2 and image 3 As shown, a microwave chip screening device and a screening method thereof include a base 3, on which a clamping tool 4 with a circuit component 2 and a plurality of power supply modules 6 for power-on are respectively arranged on the base 3, and the circuit component 2 and the power supply The signal end and the load end of the module 6 are electrically connected, and a power output port is provided at the tail of the base 3, and the control box 5 is connected to the power output port.

[0035] Such as figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, the specific structure of the clamping tooling 4 is as follows:

[0036] It includes a bottom plate 406 for carrying and positioning chip components 407, and a plurality of limit chute is set on the bottom plate 406, and the slider 401 is slidably arranged in each limit chute, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com