Substrate for testing Seebeck coefficient of semiconductor thin film, preparation and testing method

A technology of Seebeck coefficient and test method, applied in the direction of measuring device, instrument, material thermal development, etc., can solve the problems of damage to the sample to be tested, poor measurement repeatability, limited temperature tolerance of silver paste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

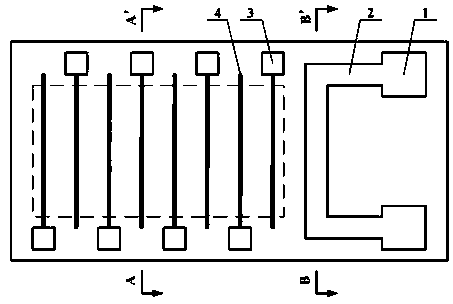

[0036] Embodiment: using polished silicon wafer as substrate, substrate length: 20mm, width: 10mm, thickness 0.2mm; insulating film layer adopts silicon oxide, deposited thickness 1μm; thermal resistance electrode, test electrode and lead wire adopt metallic titanium, thickness 500nm; The resistor is made of metal molybdenum, with a width of 1mm and a thickness of 500nm; the thermal resistance electrode is a square, with a side length of 2mm, and the center distance between two thermal resistance electrodes is 7mm; the test electrode is a square, with a side length of 1mm, a lead length of 7mm, and a line width of 0.1mm. The spacing between adjacent leads is 1.5mm.

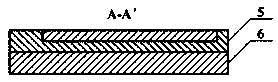

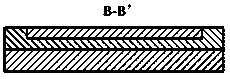

[0037] A method for preparing a substrate for testing the Seebeck coefficient of a semiconductor thin film is (see Figure 5 ): the insulating film layer 5 is deposited on the substrate 6 by thermal evaporation or magnetron sputtering; and then the photoresist is spin-coated on the insulating film layer 5, the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com