Torsion ring for microwave device testing

A microwave device and torsion ring technology, applied in the field of semiconductor device testing, can solve the problems of inconvenient operation, affecting the accuracy of test results, peripheral metal falling off, etc., to improve accuracy and stability, achieve non-destructive testing, and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The invention is applied to GaN HEMT and SiC MESFET microwave device testing. Specific embodiments are as follows.

[0026] Device and test description: 1) Gate width: 27 mm; 2) Test parameters: saturation current, output power at 3.2 GHz, gain and efficiency.

[0027] The present invention is applied to GaN HEMT and SiC MESFET microwave device testing, including the following steps:

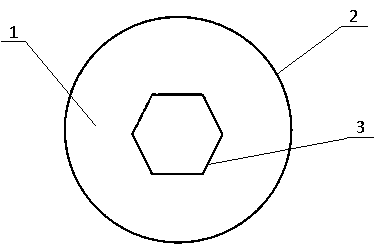

[0028] 1) According to the external dimensions of the input and output terminals of the test fixture (in this case, SMA male), use PTFE material to design the internal structure of the twist ring;

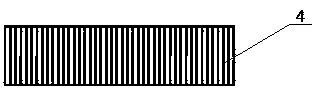

[0029] 2) Design the peripheral structure of the torsion ring, using polytetrafluoroethylene material to make the torsion ring;

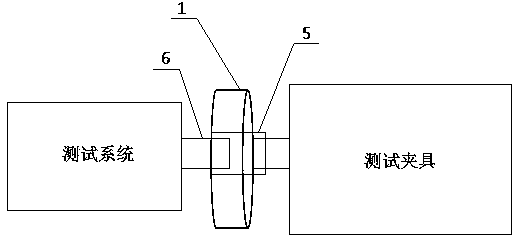

[0030] 3) Use a twist ring to connect the input and output terminals of the test fixture (in this case, SMA coaxial male connector terminal 5) to the test system coaxial connector connection (in this case, SMA coaxial female connector terminal 6);

[0031] 4) Tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com