Backlight unit and liquid crystal module

A technology of backlight unit and light-transmitting film, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven brightness, large thickness and size, and achieve the effect of thin and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

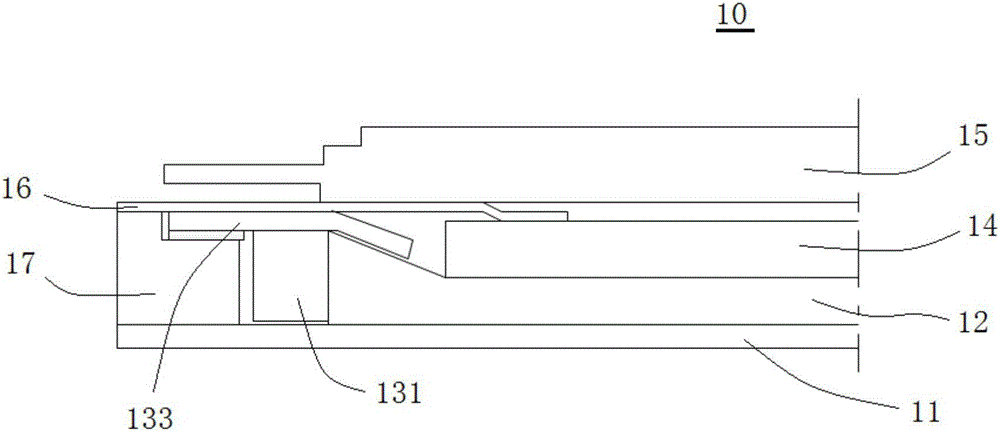

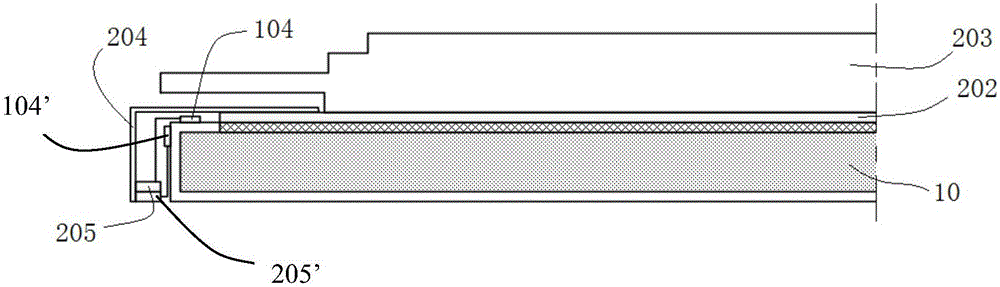

[0023] The backlight unit and the liquid crystal module of the present invention will be described in more detail below with reference to the accompanying drawings. The upper, lower, left and right in the following are all relative to the position of the drawings and should not be construed as limiting the present invention.

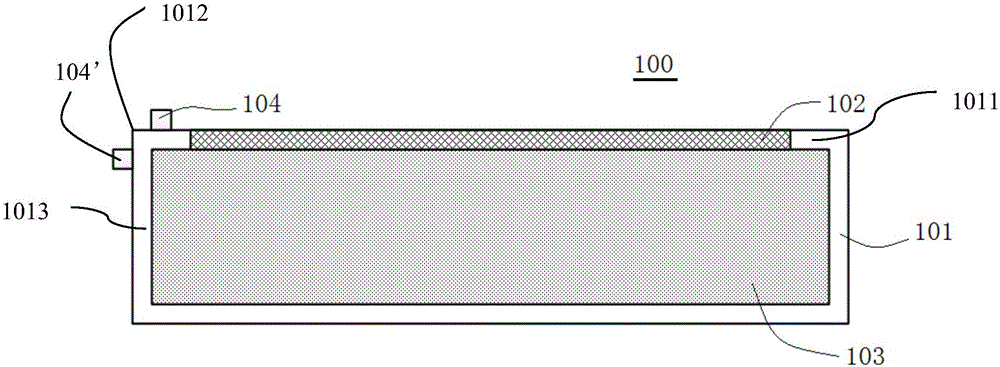

[0024] figure 2 It is a schematic diagram of the structure of the backlight unit 100 proposed by the present invention. It can be seen from the figure that the backlight unit 100 includes an opaque casing 101. The first casing wall 1011 of the casing 101 has an opening, and the light-transmitting film 102 The open part is blocked, and together with the casing 101, a sealed cavity 103 is formed inside. In order to make the sealed cavity 103 well sealed, the light-transmitting film 102 can be integrally formed with the casing 101, or the light-transmitting film 102 and the casing can be formed in other ways. The bodies 101 are combined together so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com