Train control vehicle equipment reliability prediction method based on performance degeneration

A technology of on-board equipment and prediction methods, applied in the field of train control systems, can solve problems such as inaccurate reliability of train control equipment, achieve the effect of solving untimely prediction and unreasonable response, and reducing train failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Traditional reliability research methods mostly assume that only a single device in the system degrades or fails. However, in an actual system, there may be situations where the performance of multiple devices degrades or fails, and the interrelationships between devices make the occurrence of faults relevant. Failure of a component may be caused by other components, not the end of its own life. In view of the above reasons, it is not of practical significance to predict the reliability of train control equipment simply by analyzing the life of components based on a certain performance characteristic.

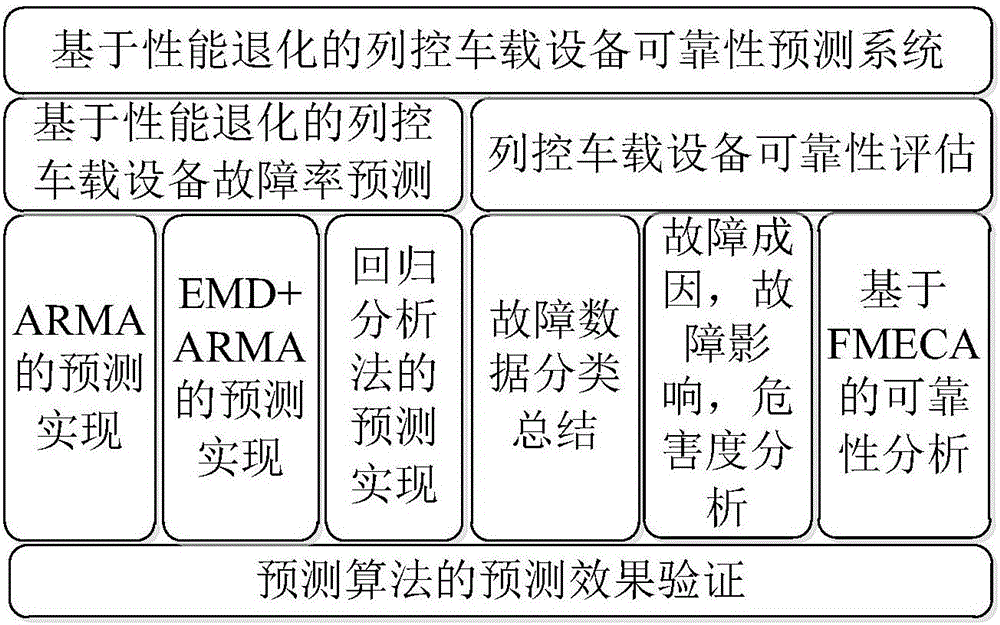

[0050] The embodiment of the present invention establishes a system framework for reliability prediction of on-board equipment for train control based on performance degradation. figure 1 As shown, the framework includes two parts: prediction of failure rate of on-board train control equipment based on performance degradation and reliability evaluation of on-board train...

Embodiment 2

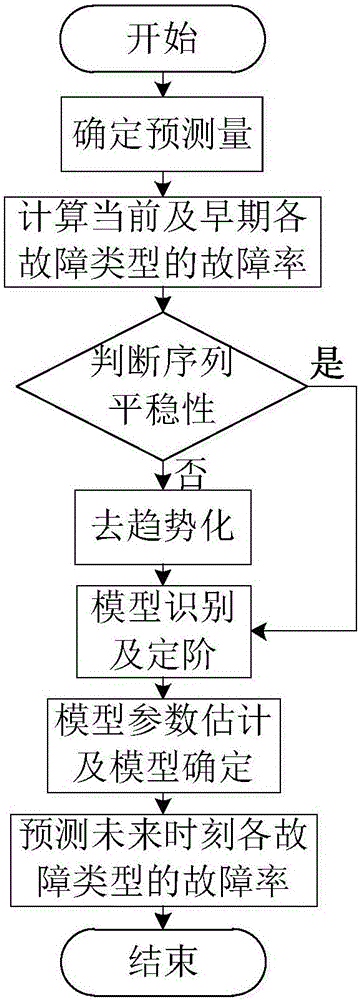

[0056] figure 2 An ARMA predictive modeling process for train control on-board equipment provided in an embodiment of the present invention, combined below figure 2 The ARMA prediction modeling process and prediction effect verification of train control on-board equipment are described.

[0057] The present invention adopts the ARMA model in the time series analysis method to establish the prediction model of each fault failure rate of the train control subsystem, and obtains the failure rate of each fault type of the train control system by calculating the current and early fault data, and according to the ARMA model, the input The failure rate of each failure type is processed, and the failure rate of each failure type is predicted at the next moment. Specific steps are as follows:

[0058] (1) Determine the predicted quantity: {the total number of failures M of a certain component or equipment within a certain period of time, the continuous running time t, the number n ...

Embodiment 3

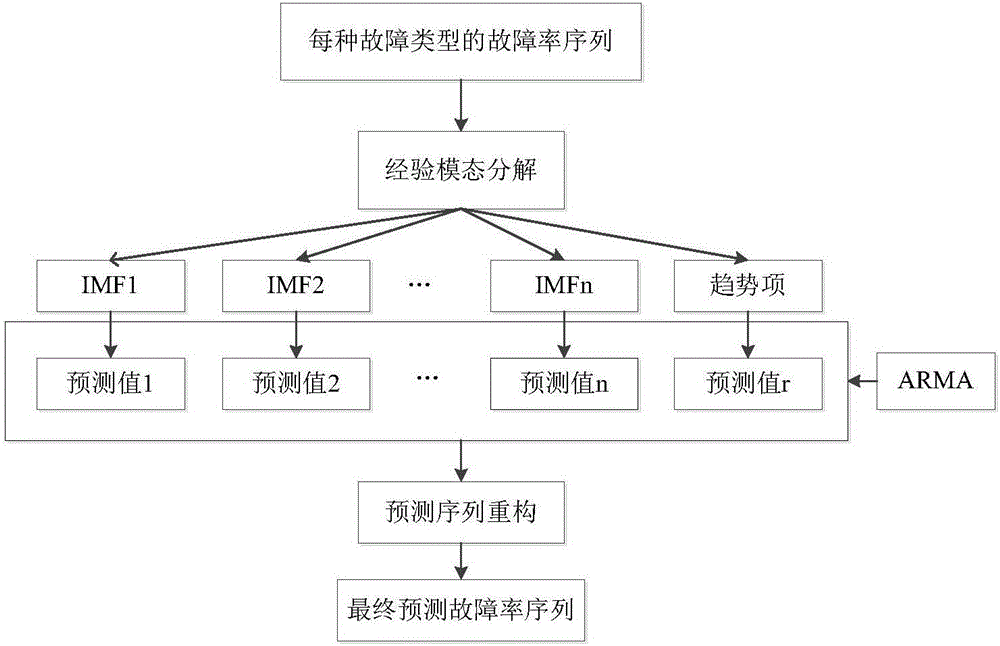

[0065] image 3 The EMD+ARMA predictive modeling process of a kind of train control on-board equipment provided for the embodiment of the present invention, combined below image 3 The EMD+ARMA prediction modeling process and prediction effect verification of train control on-board equipment are described.

[0066] The present invention adopts the ARMA failure rate prediction based on EMD, and by decomposing the failure rate series of various failure types with EMD, IMF subsequences and trend items are obtained, and then each subsequence is predicted by ARMA analysis method, and then the The predicted failure rate sequence is reconstructed, and finally the failure rate prediction sequence of various types of failures can be obtained. The specific description is as follows:

[0067] The empirical mode decomposition is performed on the original failure rate series of various fault types, and is divided into a series of subsequences according to different characteristics, namely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com