Phase-change material/air-coupled hierarchical battery heat management system

A battery thermal management and phase change material technology, applied in the field of hierarchical battery thermal management, can solve problems such as difficulty in meeting battery recycling, increasing the operating cost of electric vehicles, and amplifying the difference in battery heat production. Broad market application prospects, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

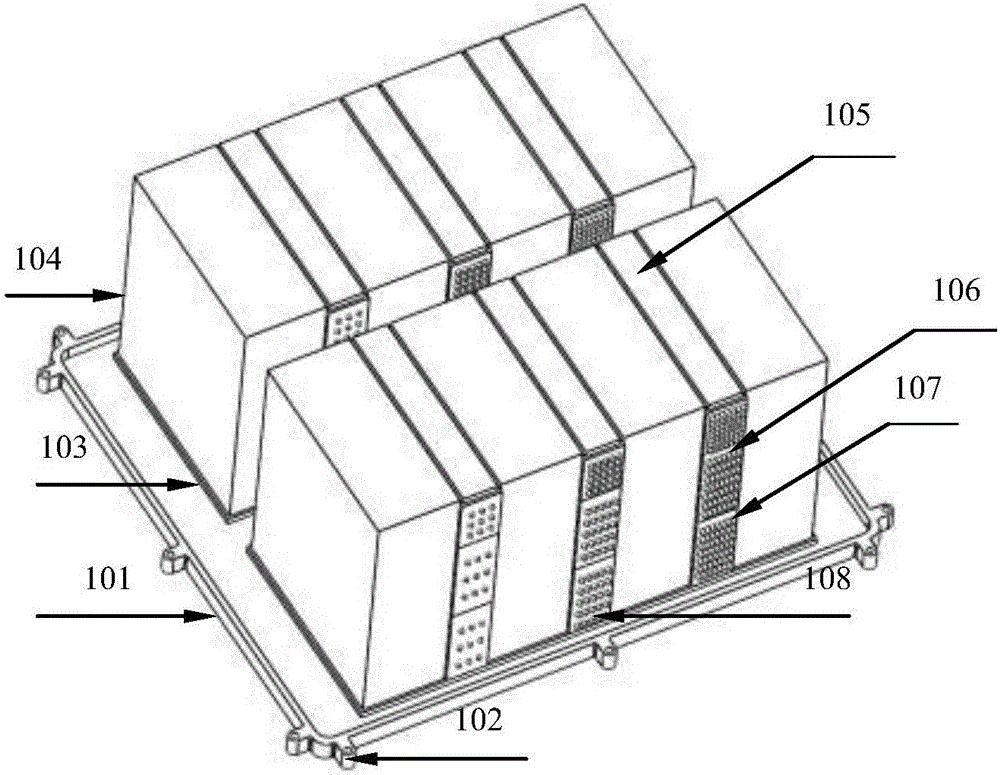

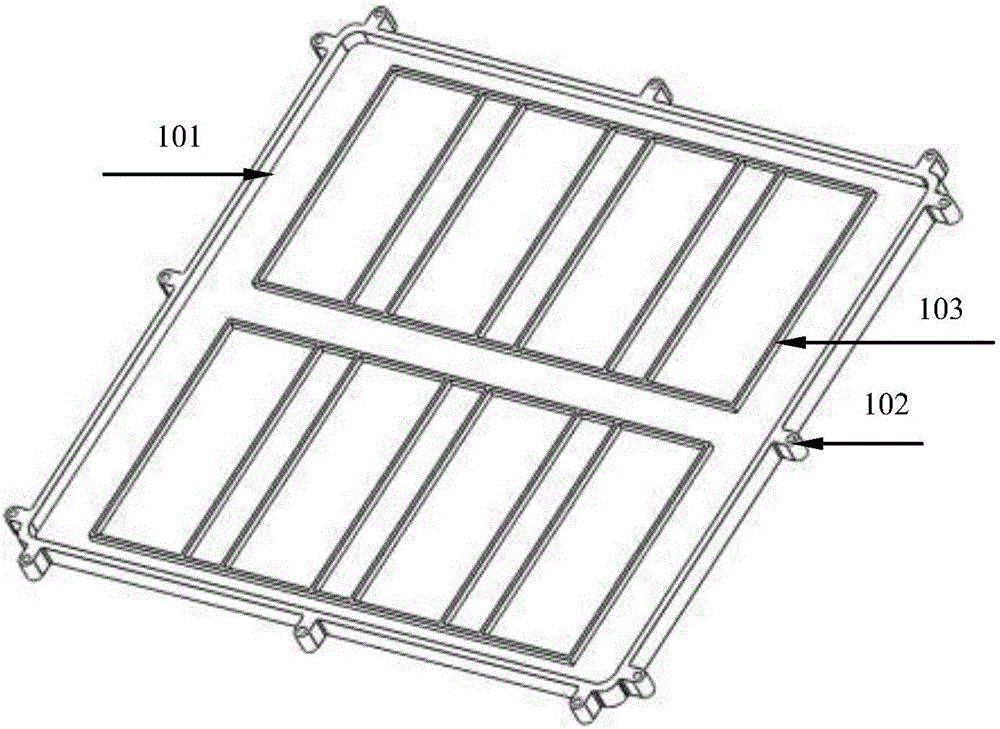

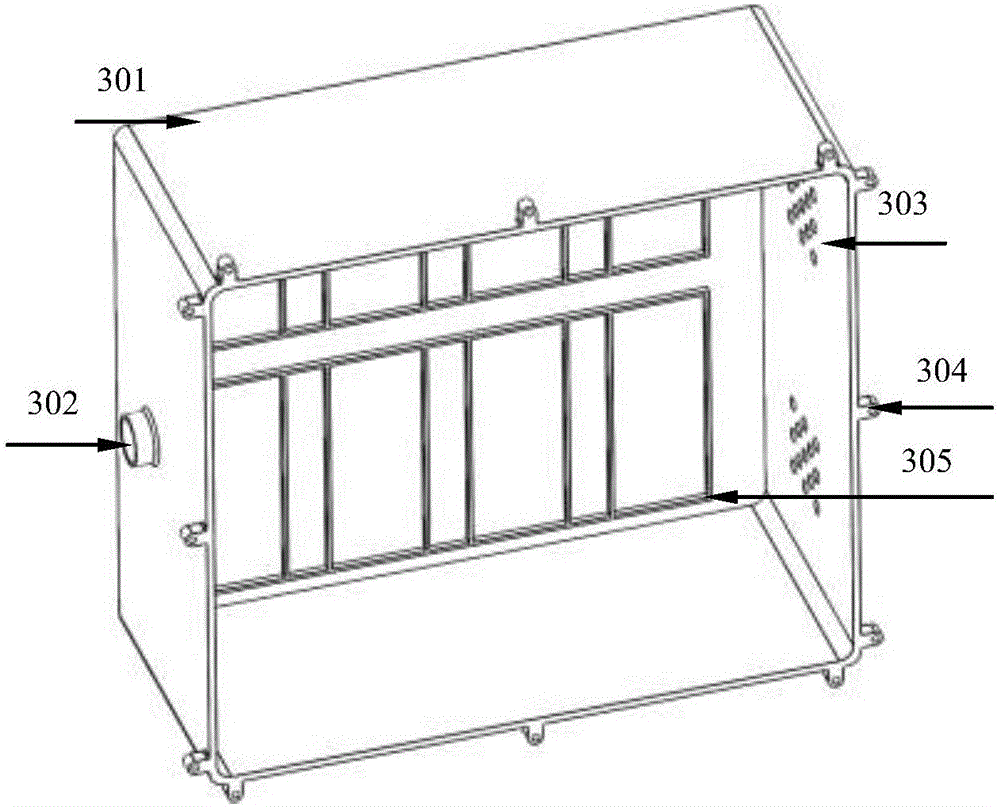

[0023] like figure 1 As shown in the figure, the phase change material / air coupled hierarchical battery thermal management system of the present invention is mainly composed of a base 101, a cover 301, an outer fin 108, an inner fin 601, an upper phase change material box 105, a middle phase change material The box 106 and the lower phase change material box 107 are constituted. A plurality of batteries 104 are arranged on the base 101, and the plurality of batteries 104 are divided into two groups and arranged on the base 101 at intervals, each group of batteries has three pieces, and the base 101 is provided with a cover 301; The base 101 is provided with a base groove 103 for installing a plurality of fixed batteries 104 and a lower phase change material box 107, and the periphery of the base 101 is provided with a base matched with the cover 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com