Carbon fiber composite core optical fiber wire strain clamp

A tension clamp, composite core technology, applied in the direction of optical fiber/cable installation, adjusting/maintaining mechanical tension, etc. The effect of preventing damage and ensuring signal transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

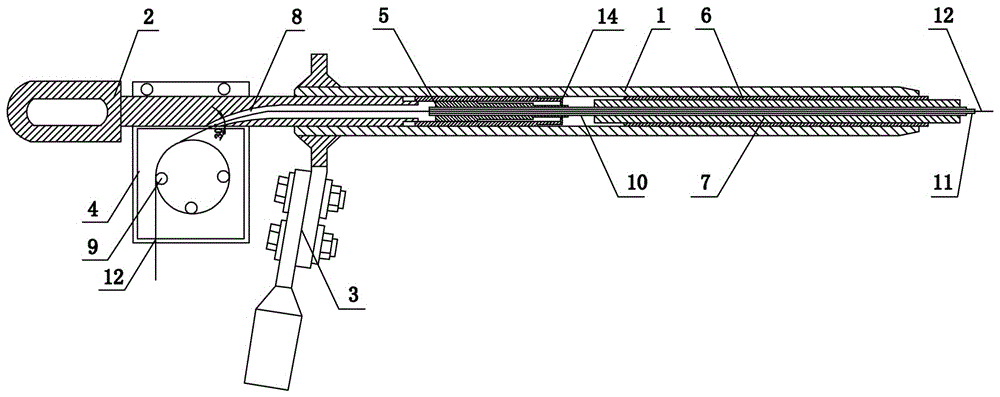

[0027] Such as figure 1 As shown, the present invention includes a cable clamp body 1, a steel anchor 2, a drainage plate 3 and an optical fiber protection box. The optical fiber protection box includes two sealed and fastened box covers 4, and the steel anchor 2 is threadedly connected to the left end of the cable clamp body 1 for drainage. The plate 3 is fixedly connected to the outer wall of the wire clamp body 1 by bolts, the wire clamp body 1 is a hollow tube, the left end of the wire clamp body 1 is fixedly connected to the wedge-shaped clamp support 14, and the matching wedge-shaped clamp 5 is installed in the wedge-shaped clamp support 14 , the right end of the clamp body 1 is equipped with an inner liner 6, and an arc-shaped through hole 8 is provided in the steel anchor 2, and the right end of one end of the arc-shaped through hole 8 is connected with the clamp body 1, and the center line of the arc-shaped through hole 8 The angle α between the tangent line of the mi...

Embodiment 2

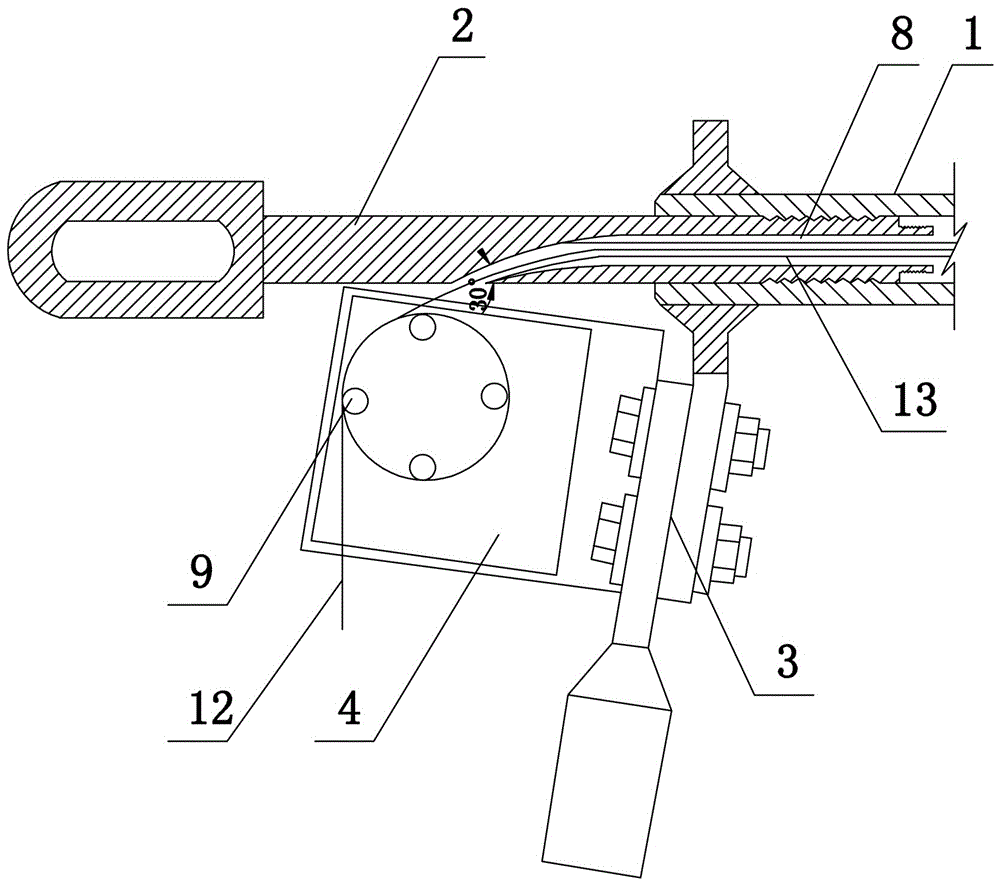

[0030] The present invention includes a cable clamp body 1, a steel anchor 2, a drainage plate 3 and an optical fiber protection box, the optical fiber protection box includes two sealed and fastened box covers 4, the steel anchor 2 is threaded to the left end of the cable clamp body 1, and the drainage plate 3 passes through the Bolts are fixedly connected to the outer wall of the wire clamp body 1, the wire clamp body 1 is a hollow tube, the left end in the wire clamp body 1 is fixedly connected to the wedge-shaped clamp support 14, and the matching wedge-shaped clamp 5 is installed in the wedge-shaped clamp support 14, and the wire clamp The right end of the main body 1 is equipped with an inner liner 6, an arc-shaped through hole 8 is provided in the steel anchor 2, and a transparent rubber tube 13 is arranged in the arc-shaped through-hole 8, and the right end of one end of the arc-shaped through hole 8 communicates with the clamp body 1. The angle α between the tangent of...

Embodiment 3

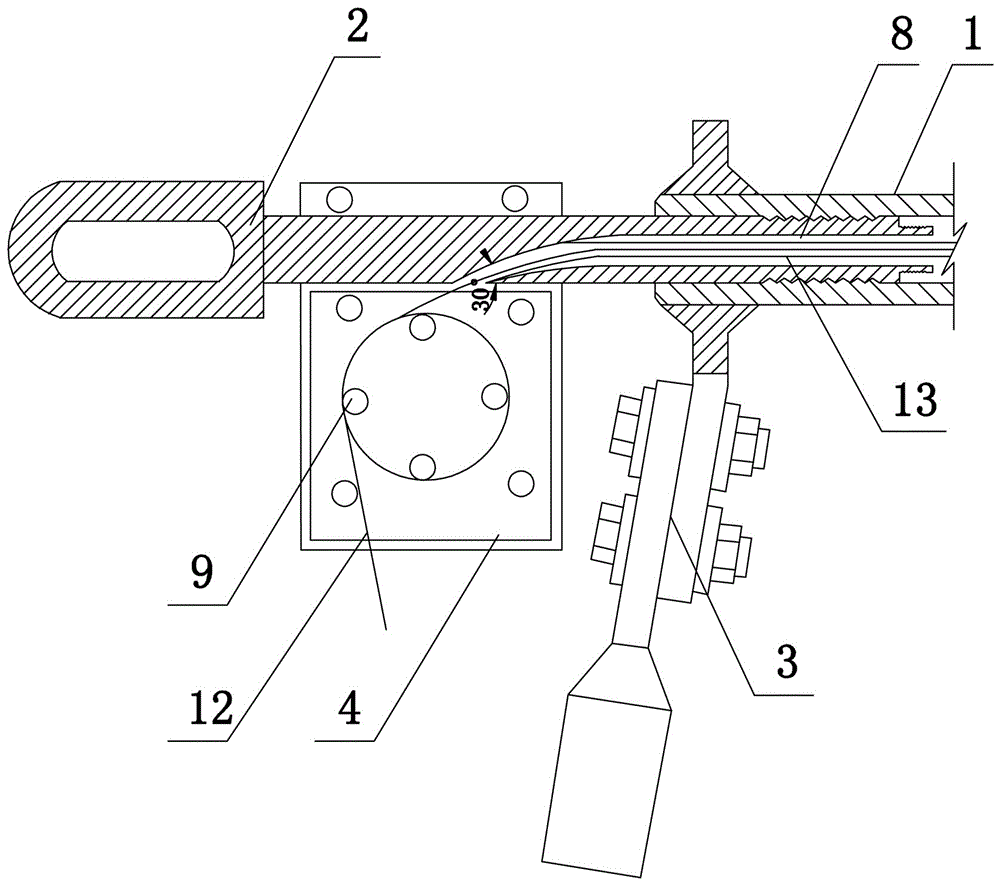

[0033]The present invention includes a cable clamp body 1, a steel anchor 2, a drainage plate 3 and an optical fiber protection box, the optical fiber protection box includes two sealed and fastened box covers 4, the steel anchor 2 is threaded to the left end of the cable clamp body 1, and the drainage plate 3 passes through the Bolts are fixedly connected to the outer wall of the wire clamp body 1, the wire clamp body 1 is a hollow tube, the left end in the wire clamp body 1 is fixedly connected to the wedge-shaped clamp support 14, and the matching wedge-shaped clamp 5 is installed in the wedge-shaped clamp support 14, and the wire clamp The right end of the main body 1 is equipped with an inner liner 6, an arc-shaped through hole 8 is provided in the steel anchor 2, and a transparent rubber tube 13 is arranged in the arc-shaped through-hole 8, and the right end of one end of the arc-shaped through hole 8 communicates with the clamp body 1. The angle α between the tangent of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com