A device for a production line of a steckel rolling mill

A technology for the coil rolling mill and production line, which is applied in the direction of metal rolling, metal rolling, cooling bed, etc., and can solve the problems of rear-end collision and collision with cooling bed equipment, etc., so as to improve the yield rate, avoid production accidents, and avoid head-to-tail collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail now in conjunction with accompanying drawing.

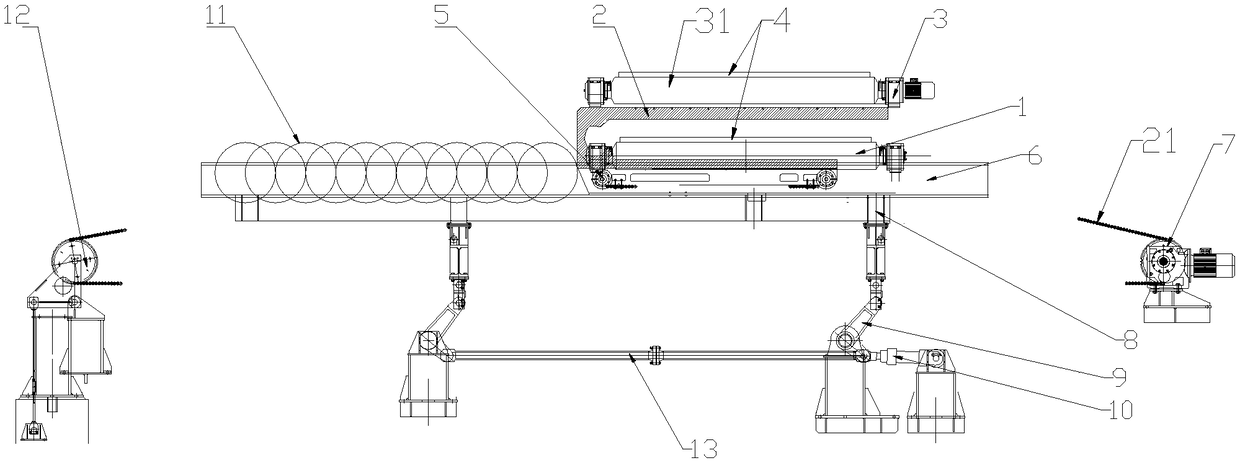

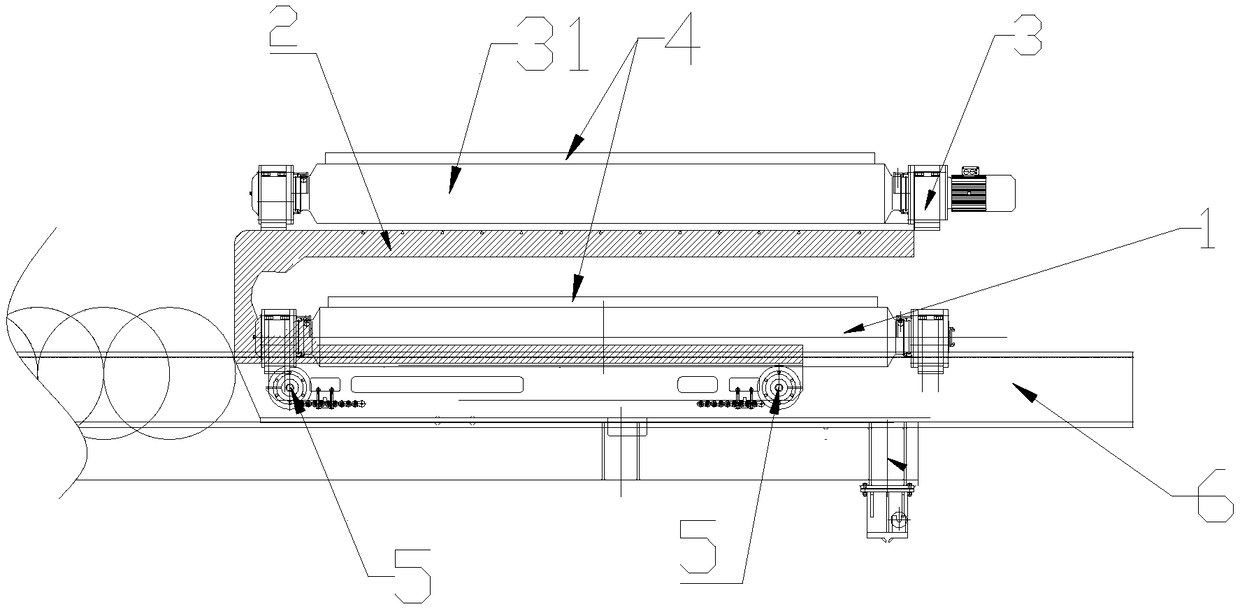

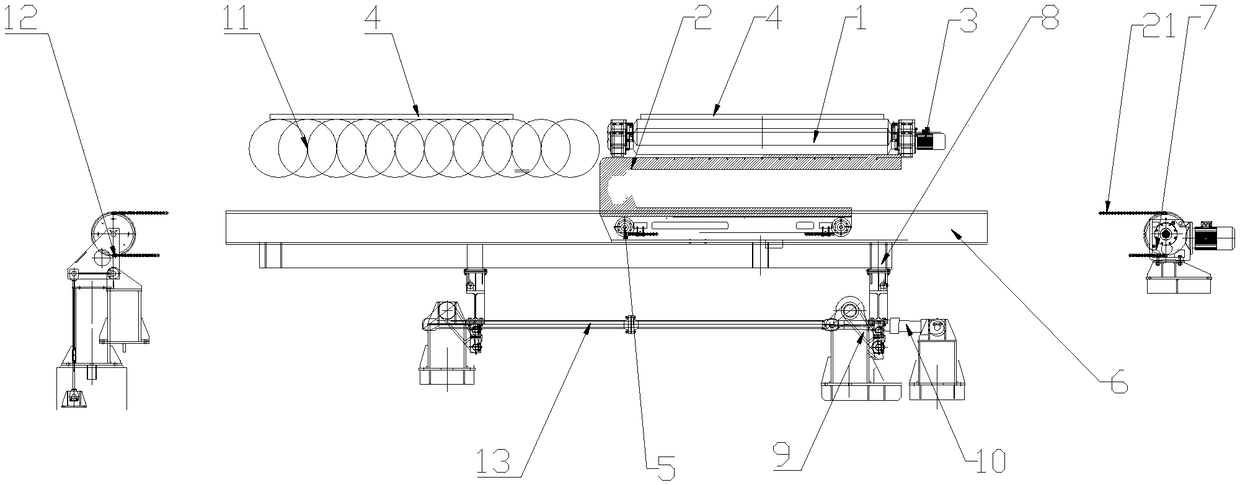

[0022] according to Figures 1 to 2 The shown device for a coil rolling mill production line includes a conveying roller table 1, a trolley slideway 6, and a flat C-shaped trolley 2. The flat C-shaped trolley 2 is provided with an upper support frame, a lower support frame and a connecting vertical plate. The upper support frame is equipped with a receiving roller table 31, the space between the upper support frame and the lower support frame is reserved for the steel plate conveying roller table 1, and the two sides of the lower part of the flat C-shaped trolley 2 are equipped with 4 wheels 5, the wheels 5 is assembled in the trolley slideway 6 and can move along the trolley slideway 6. The flat C-shaped trolley 2 is equipped with a chain 21, and the chain 21 is connected with the flat C-shaped trolley to form a closed-loop system. One side of the chain 21 is assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com