Upsetting method of cylindrical ingot blank or bar with large height to diameter ratio

A cylindrical and ingot technology, which is applied to the open forging field of cylindrical ingots or bars, can solve the problem of uneven structure, reduce the height-diameter ratio, and improve the uniformity of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment the present invention is further described in detail

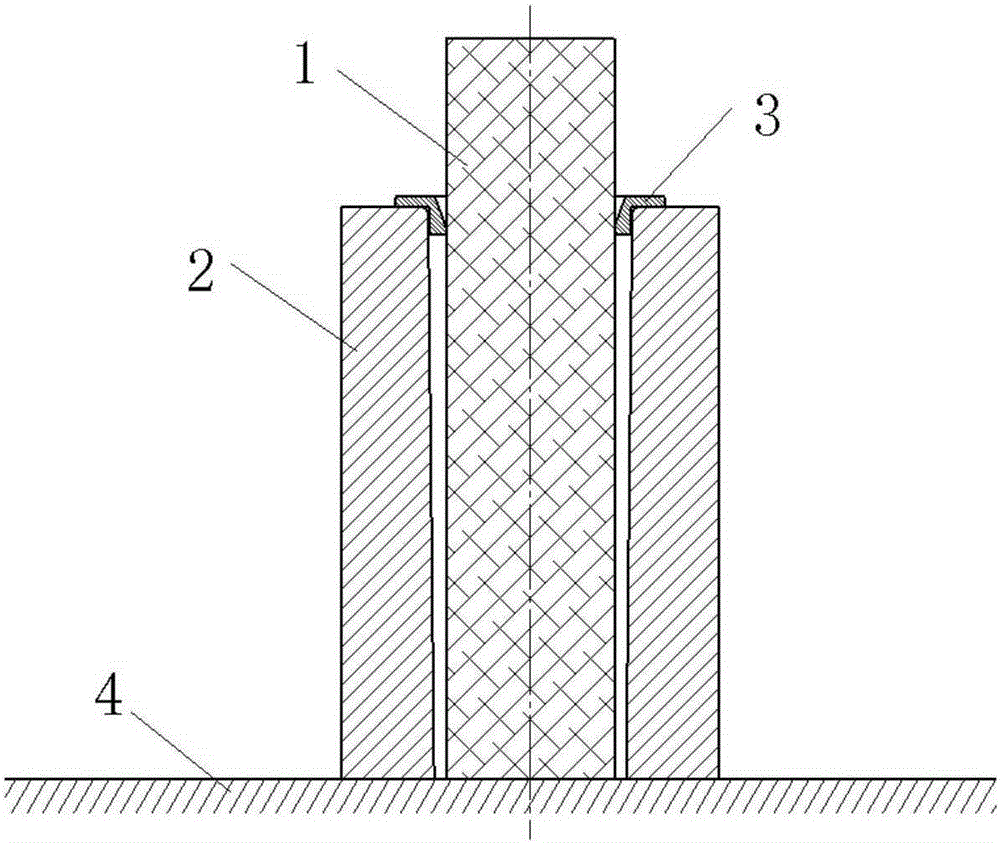

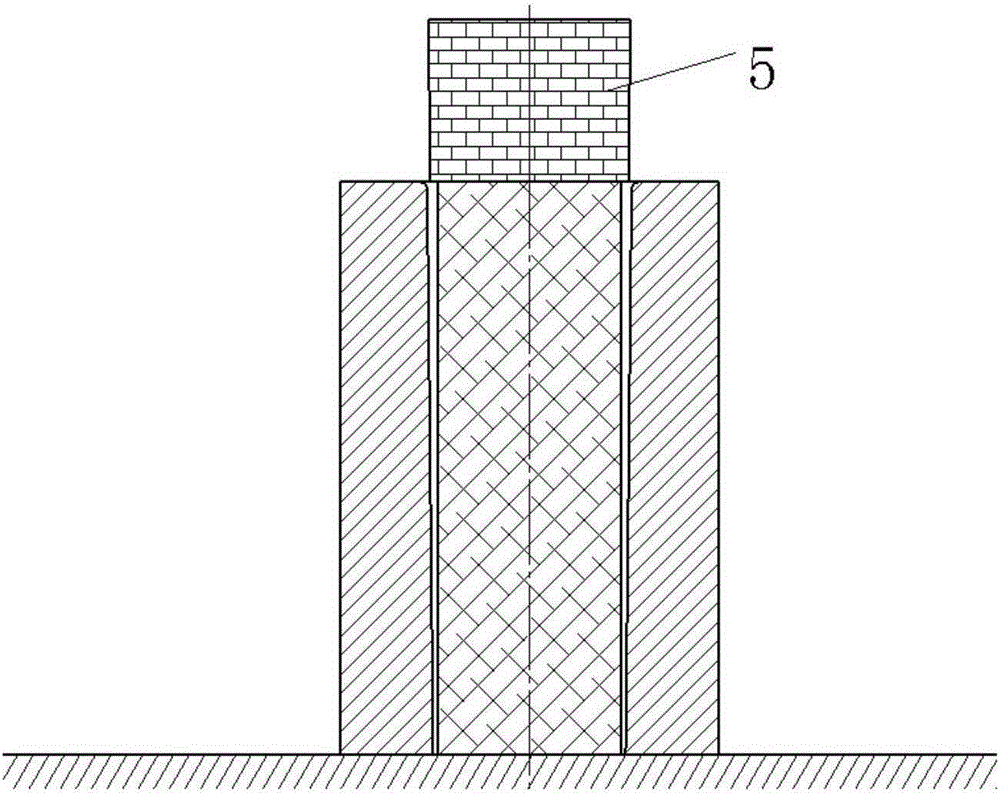

[0019] The turbine disk for a certain type of engine is made of FGH96 powder superalloy. Currently, due to the difficulty in smelting this material, only ingots or bars with a diameter of 175mm can be smelted. Therefore, the diameter of the ingot or bar for forging the turbine disk is 175mm. , the height is 750mm, and the ratio of height to diameter is 4.2. The billet or bar billet opening process needs to upset the billet or bar from 750mm to 430mm, and the total upsetting amount is 320mm. The basic situation of the tire membrane used in the billet opening process is that the tire mold is hollow cylindrical, with an outer diameter of 450mm and a height of 530mm. A small amount of slope is set in the inner hole of the tire mold, of which the diameter of the large end is 231mm and the diameter of the small end is 221mm. , to ensure that the blank can be smoothly taken out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com