A kind of method for liquid-phase selective hydrogenation of carbon three fractions

A technology for selective hydrogenation and fractionation, which is applied in the fields of hydrocarbons, chemical instruments and methods, and hydrocarbon purification/separation, etc. It can solve the problems of short catalyst operating life, complex hydrogenation procedures, and low catalyst activity, and reduce the reaction time. The effect of energy consumption, simplifying the liquid phase selective hydrogenation process of carbon three fractions, and improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

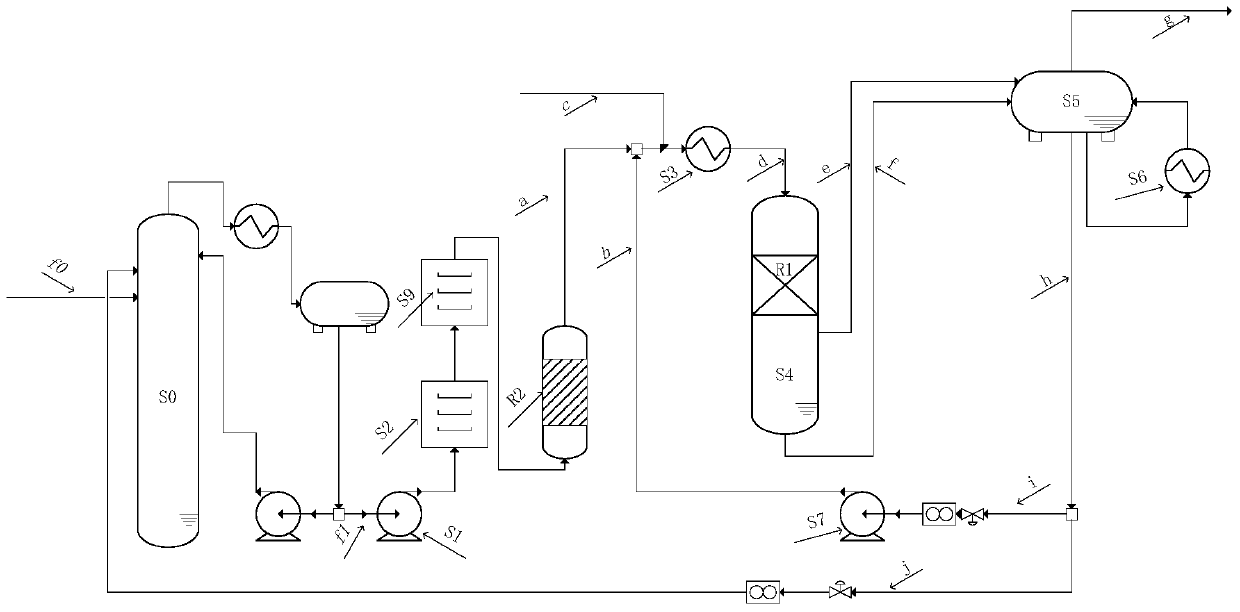

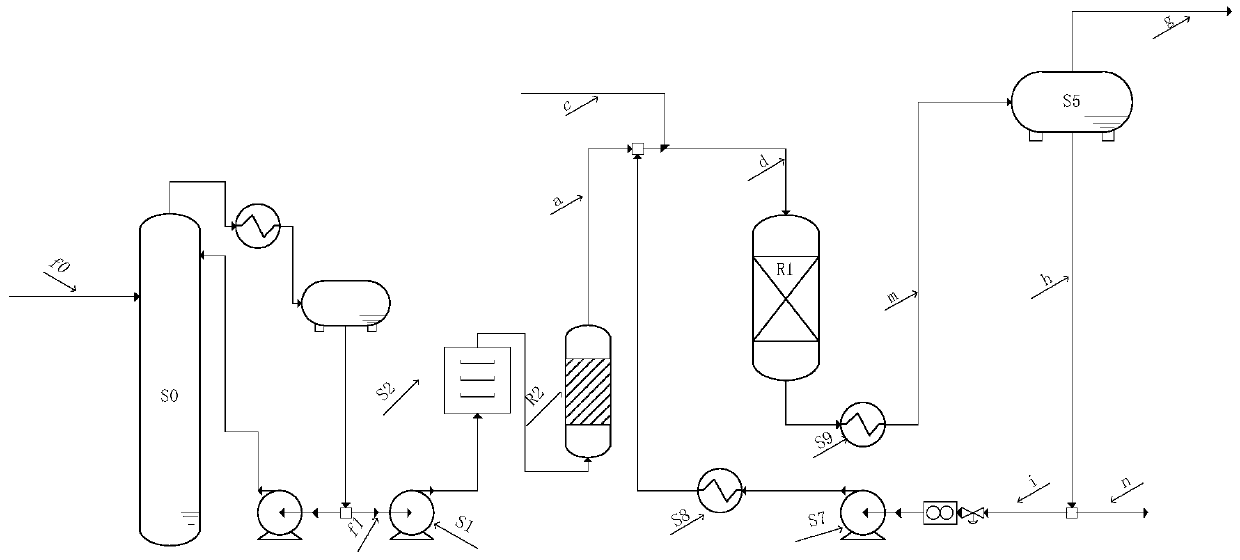

[0079] according to figure 1 The flow process of the carbon three liquid phase selective hydrogenation shown in the present invention.

[0080] The material f1 (flow rate is 170t / h, the sum of the molar content of propyne and propadiene is 3% by the material f1 (flow rate is 170t / h, the molar content sum of propyne and propadiene is 3%, water mol content is 25ppm, the molar content of methanol is 170ppm, and the molar content of arsenic is less than 3ppb) through pump S1, it passes through water remover S2, methanol remover S9 (S2 and S9 are filled with 3A molecular sieve produced by UOP Company) and remover Arsenic reactor R2 (the reactor is filled with R3-12 catalyst produced by BASF company, the reaction temperature is 37 ° C, and the reaction pressure is 2.4 MPa), to obtain fresh carbon three cuts a (the sum of the molar content of propyne and propadiene 3%, the molar content of water is less than 5ppm, the molar content of methanol is less than 10ppm, and the molar conte...

Embodiment 2

[0090] According to the method described in embodiment 1, the difference is that the flow rate of the fresh carbon three fraction a is 190t / h, the flow rate of the circulating carbon three stream b is 90t / h, and the flow rate of the gas phase stream g is 105t / h, correspondingly, by Adjust the flow rate of the gaseous phase stream g entering the propylene rectification tower to adjust the pressure of the selective hydrogenation reactor to 2.45MPa.

[0091] By adopting the method provided in this example, the molar content of propyne and propadiene in the gas phase stream g obtained after gas-liquid separation is less than 100 ppm. After adopting the process method, the operating period of the selective hydrogenation catalyst reaches more than 8 months.

Embodiment 3

[0093] according to figure 1 The flow process of the carbon three liquid phase selective hydrogenation shown in the present invention.

[0094] The material f1 (flow rate is 140t / h, the molar content sum of propyne and propadiene is 2.4% by the material f1 (flow rate is 140t / h, the molar content sum of propyne and propadiene is 2.4%, water mole) content is 25ppm, the molar content of methanol is 150ppm, and the molar content of arsenic is lower than 3ppb) through the pump S1 and then through the water remover S2, the methanol remover S9 (both S2 and S9 are filled with 3A molecular sieves produced by UOP Company) and the removal Arsenic reactor R2 (the reactor is filled with R3-12 catalyst produced by BASF company, the reaction temperature is 39 ℃, and the reaction pressure is 2.35MPa) to obtain fresh carbon three cuts a (the sum of the molar content of propyne and propadiene is 2.4%, the molar content of water is less than 5ppm, the molar content of methanol is less than 10pp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com