A method for liquid-phase selective hydrogenation of carbon three fractions

A technology for selective hydrogenation and fractionation, applied in the direction of hydrocarbons, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve the problems of ineffective removal and high energy consumption in the hydrogenation process, and achieve simplified C3 fractionation Liquid-phase selective hydrogenation process, reducing reaction energy consumption and improving removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

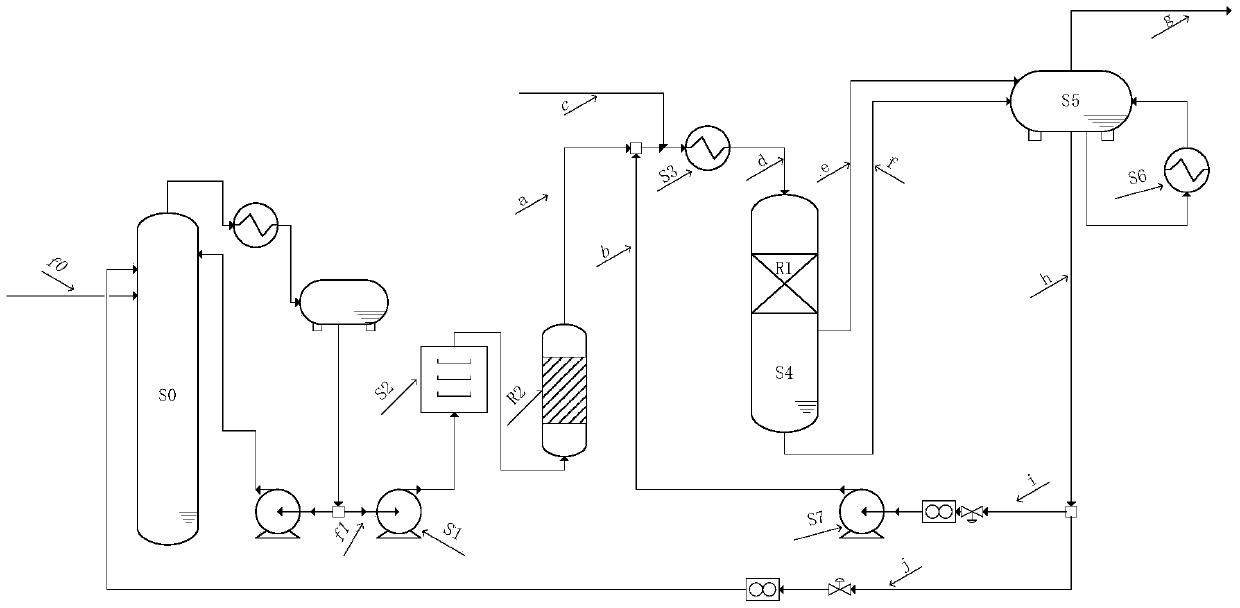

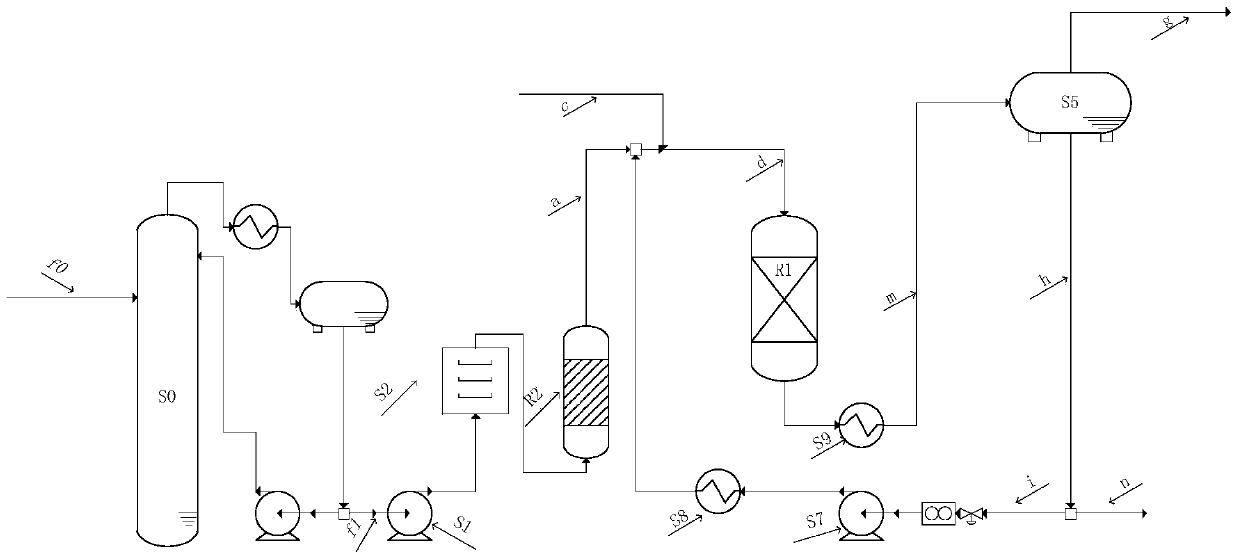

[0063] according to figure 1 The flow process of the carbon three liquid phase selective hydrogenation shown in the present invention.

[0064] The material f1 extracted from the top of the depropanizer S0 obtained by reacting the C3 material f0 in the depropanizer S0 passes through the water dryer S2 and the dearsenic reactor R2 sequentially through the pump S1.

[0065] The fresh C3 fraction a (flow rate is 180t / h, the sum of the molar content of propyne and propadiene is 3%) and the circulating C3 stream b (flow rate is 90t / h) extracted from the dearsenic reactor R2 After mixing, mix with hydrogen c (hydrogen flow rate is 380kg / h, hydrogen purity is 95%, other impurity is methane) after S3 heat exchange, obtained mixture d enters reactor from the top of selective hydrogenation reactor, from above Down through the selective hydrogenation catalyst bed R1 in the selective hydrogenation reactor, it is in contact with the carbon three liquid phase selective hydrogenation cataly...

Embodiment 2

[0074] According to the method described in embodiment 1, the difference is that the flow rate of the fresh carbon three fraction a is 210t / h, the flow rate of the circulating carbon three stream b is 100t / h, and the flow rate of the gas phase stream g is 110t / h, correspondingly, by Adjust the flow rate of the gaseous phase stream g entering the propylene rectification tower to adjust the pressure of the selective hydrogenation reactor to 2.35MPa.

[0075] By adopting the method provided in this example, the molar content of propyne and propadiene in the gas phase stream g obtained after gas-liquid separation is less than 200ppm.

Embodiment 3

[0077] according to figure 1 The flow process of the carbon three liquid phase selective hydrogenation shown in the present invention.

[0078] The material f1 extracted from the top of the depropanizer S0 obtained by reacting the C3 material f0 in the depropanizer S0 passes through the water dryer S2 and the dearsenic reactor R2 sequentially through the pump S1.

[0079] The fresh C3 fraction a (flow rate is 150t / h, the sum of the molar content of propyne and propadiene is 2.5%) and the circulating C3 stream b (flow rate is 75t / h) extracted from the dearsenic reactor R2 After mixing, mix with hydrogen c (hydrogen flow rate is 290kg / h, hydrogen purity is 95%, other impurity is methane) after S3 heat exchange, obtained mixture d enters reactor from the top of selective hydrogenation reactor, from above Down through the selective hydrogenation catalyst bed R1 in the selective hydrogenation reactor, it is in contact with the carbon three liquid phase selective hydrogenation cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com