System for enlarging cogeneration centralized heat supply scale

A technology for central heating and cogeneration, applied in hot water central heating systems, heating systems, heating fuels, etc., can solve problems such as prominent conflicts in distribution of interests, difficulty in determining heat prices, and inability to set up peak-shaving heat sources, etc. Achieve the effect of fully exerting heating capacity, improving heating efficiency, and solving the conflict of interest distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in combination with specific embodiments.

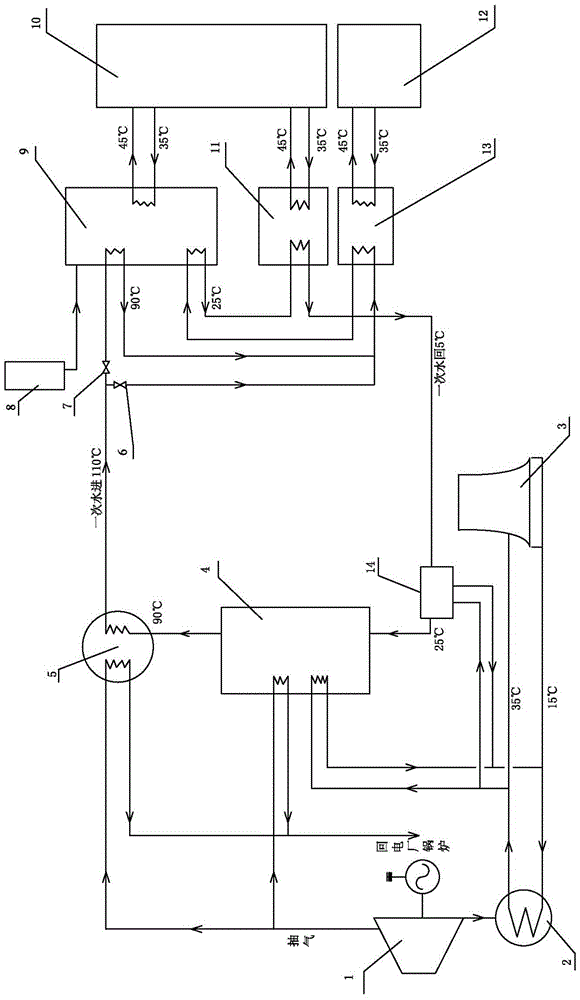

[0018] Such as figure 1 As shown in the figure, a system for enlarging the scale of centralized heat supply for combined heat and power generation, the high-temperature primary heating network water supply from the steam-water heat exchanger 5 of the thermal power plant is divided into two paths, and one path enters the multi-heat source-driven absorption heat pump 9 as a driving heat source , after releasing heat and cooling down, it enters the heat exchanger A13 to exchange heat with the secondary heat network of the original user 12; the other one directly enters the heat exchanger A13 to exchange heat with the secondary heat network of the original user 12; the two-way heat network water supply pipe The control valve A6 and the control valve B7 are respectively set on the road. After heat exchange and cooling from the heat exchanger A13, the return water of the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com