Vibration adjustable walnut picking machine

An adjustable, picking machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of large number of workers, low efficiency, high labor intensity, etc., meet workers' technical requirements and reduce harvesting. Cost, the effect of simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

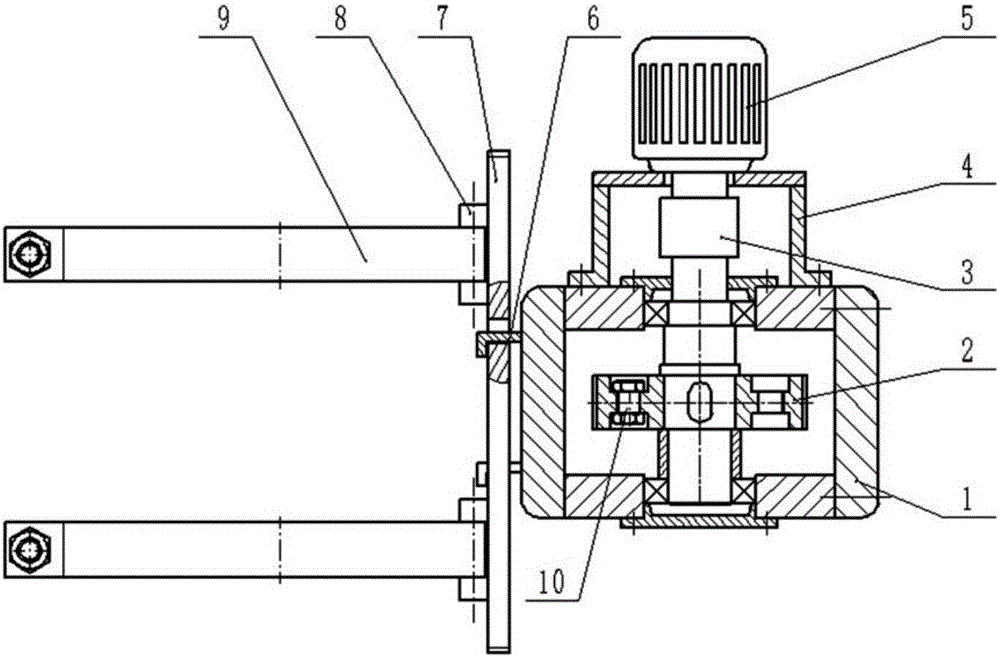

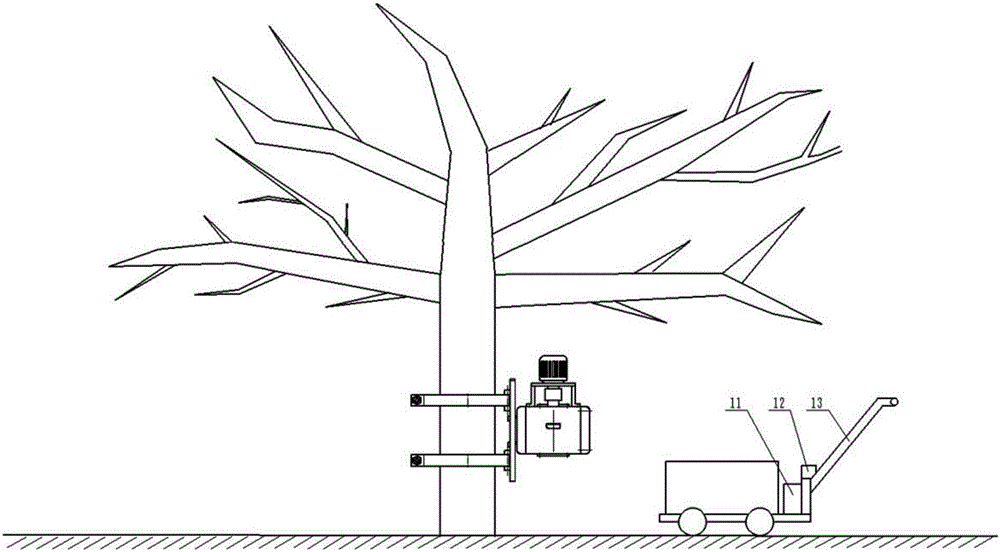

[0021] A vibration-adjustable walnut picker, which mainly includes a trunk clamping device, a two-way connecting plate 7, a double-ear support 8, a trunk clamp 9, a hook 6, an adjustable vibration excitation device, a speed controller 12, Rechargeable battery 11 and mobile trolley 13, the described vibration-adjustable walnut picker is characterized in that the trunk clamping device is fixed on the trunk by the trunk clamper 9 on the front side of the two-way connecting plate 7, and the two-way connecting plate 7 is opened There is a square through hole, and the hook 6 fixed on the front side of the adjustable vibration excitation device is hooked on the square through hole of the two-way connection plate 7, so that the adjustable vibration excitation device is fixedly connected with the two-way connection plate 7, and the adjustable vibration excitation device The vibration generated by the device is transmitted to the trunk, and the trunk clamping device includes a trunk clam...

Embodiment 2

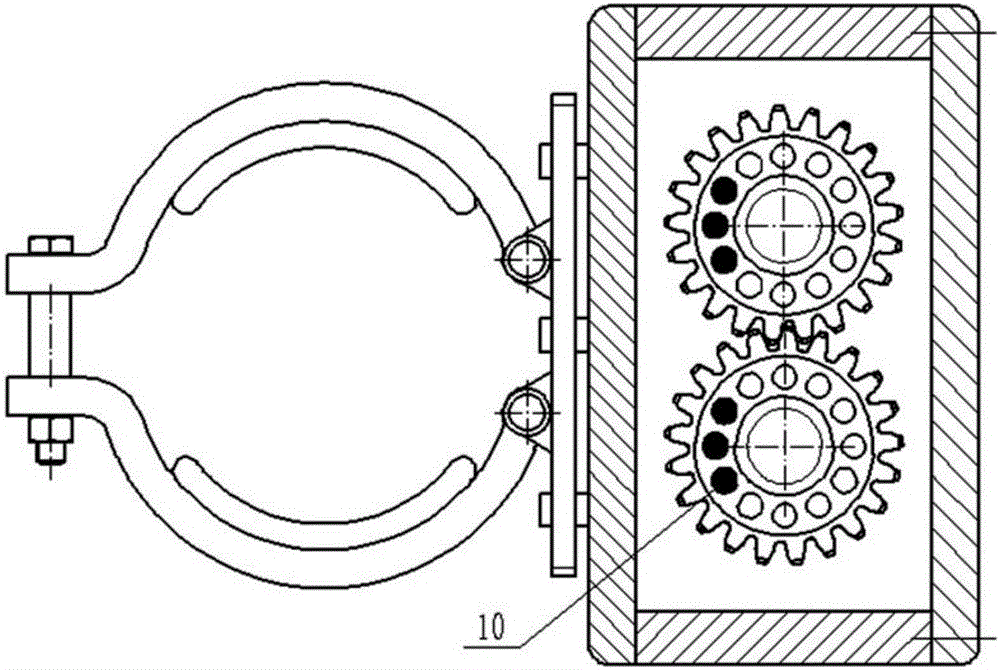

[0023]Described trunk clamping device comprises trunk clamp 9, two-way connection plate 7, two-ear support 8, arc clamping arm, rubber protection pad, pin shaft, lock bolt and lock nut, described two-way The connection plate 7 is a rectangular steel plate, and two double-ear supports 8 are welded on the top and bottom of the front side, which are symmetrically distributed on both sides of the transverse center line of the two-way connection plate 7. There are 3 square through holes on the plate, and the distance from the center of the plate is equal. And it is distributed in an inverted triangle, and is arranged at intervals with the hook 6. The trunk clamper 9 includes two groups of arc-shaped clamping arms up and down, each group has one left and one right, and its tail is connected to the two-way connecting plate 7 through a pin shaft. The double-ear support 8 on the top is hinged, and the left and right two arc-shaped clamping arms can rotate around the pin shaft of the tai...

Embodiment 3

[0025] The adjustable vibrator includes a vibrator casing 1, an adjustable center of gravity gear 2, an eccentric mass block 10, a driving shaft, a driven shaft, a bearing, a bushing, a bearing end cover, and the internal parts of the adjustable vibrator A pair of center-of-gravity adjustable gears 2 are installed on the two shafts, and the driving shaft is connected to the 5-axis speed regulating motor through a coupling 3. The vibration exciter casing 1 includes a machine base and a machine cover, which are welded by steel materials. The left and right side walls of the machine base are processed with pick-up structures for easy handling. Two bearing holes are symmetrically processed on the upper and lower side walls to install bearings and bearing end covers. On the upper and lower side walls of the vibrator casing 1, the center-of-gravity adjustable gear 2 is composed of a pair of plate-type gears of the same size, and an even number of internal thread holes are evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com