Traction, rolling and unrolling device of heat preservation quilt for solar-panel greenhouse

A solar panel greenhouse and thermal insulation quilt technology, which is applied in greenhouse cultivation, application, climate change adaptation, etc., can solve the problems of unfavorable thermal insulation, affecting crop growth, affecting sunlight injection, etc., and achieves the effect of good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

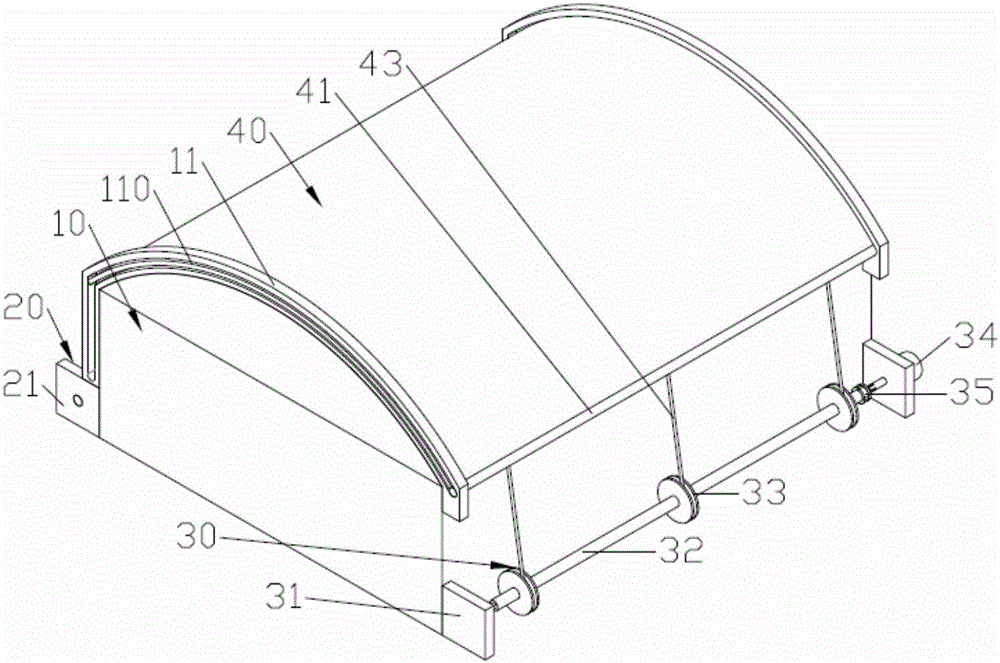

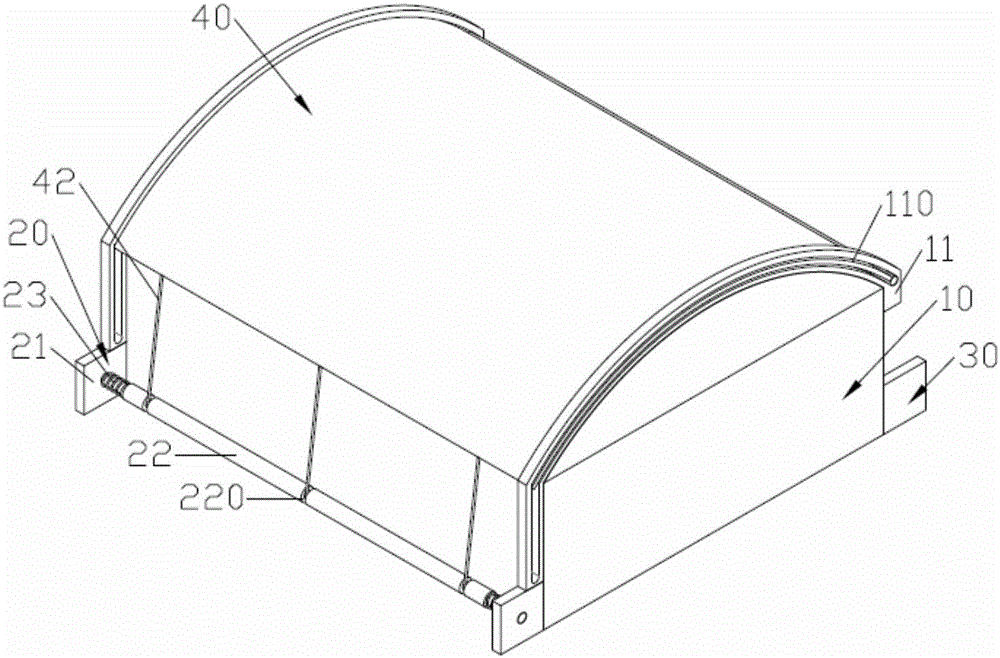

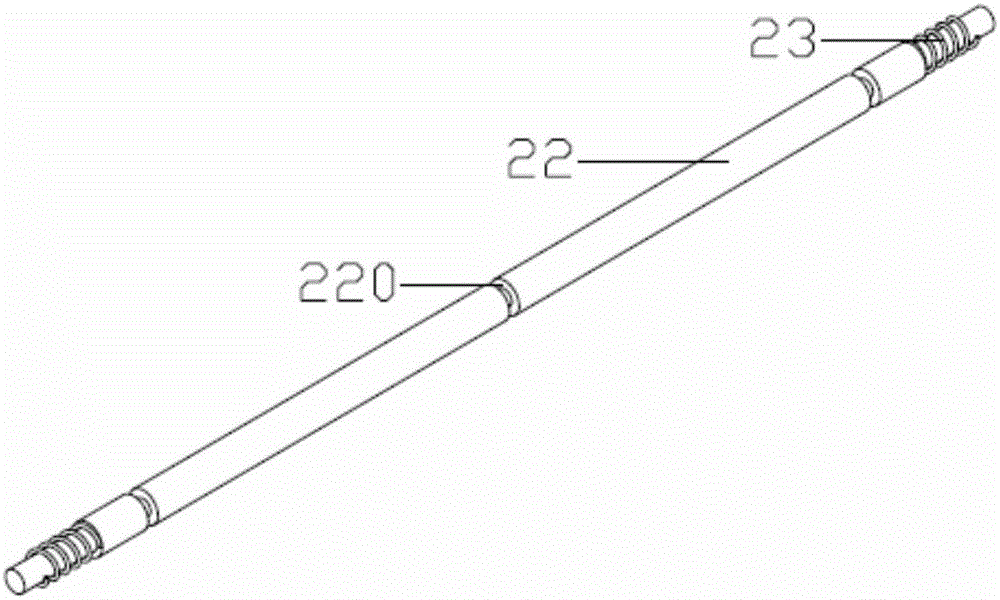

[0018] Such as figure 1 , figure 2 As shown, a solar panel greenhouse is pulled and unwrapped by thermal insulation, including a solar panel greenhouse 10, a laying device 30, a retracting device 20 and a thermal insulation quilt 40; the top of the solar panel greenhouse 10 is arched; the laying device 30, The retracting devices 20 are respectively arranged on the two side walls of the solar panel greenhouse 10; one end of the thermal insulation quilt 40 is fixed with a rolling paving guide rod 41, and the other end is fixed with a number of evenly distributed winding and unwinding ropes 42; A number of evenly distributed laying wire ropes 43 are fixed; the other end of the laying wire rope 43 is fixed on the laying device 30; the other end of the retracting wire rope 42 is fixed on the retracting device 20; A pair of front and rear symmetrical guide plates 11 on the wall; roll paving guide rod 41 slides and is arranged between a pair of guide plates 11; winding line 42 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com