On-pipe type water irrigator

An irrigator and flow channel technology, which is applied to the field of on-pipe irrigators, can solve the problems of non-point source pollution, nutrient leaching, small size of the inlet and outlet of the irrigator and flow channels, and achieves multi-flow level adjustment and anti-clogging Good performance and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

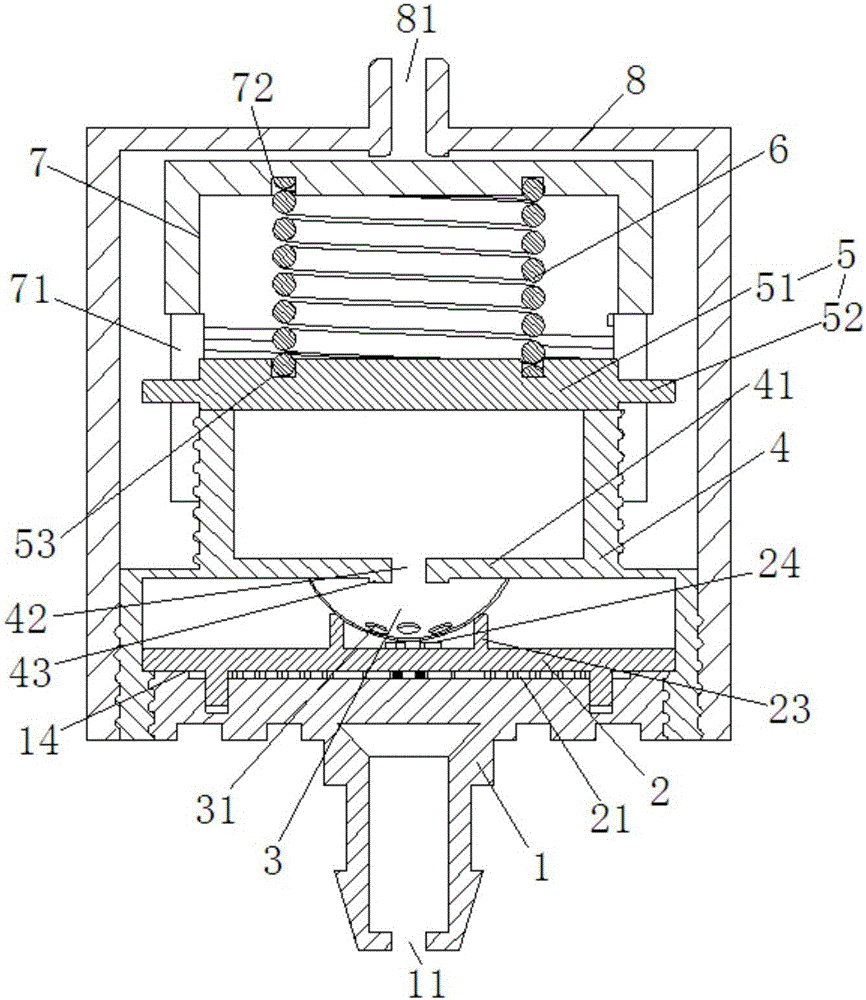

[0029] Such as figure 1 As shown, the present invention proposes a pipe-mounted emitter, which includes an inlet water guide part 1, a flow channel cover plate 2, a circular shrapnel 3, a base 4, a scraper cover plate 5, an elastic support part 6, an adjustment Cavity 7 and outlet cavity 8.

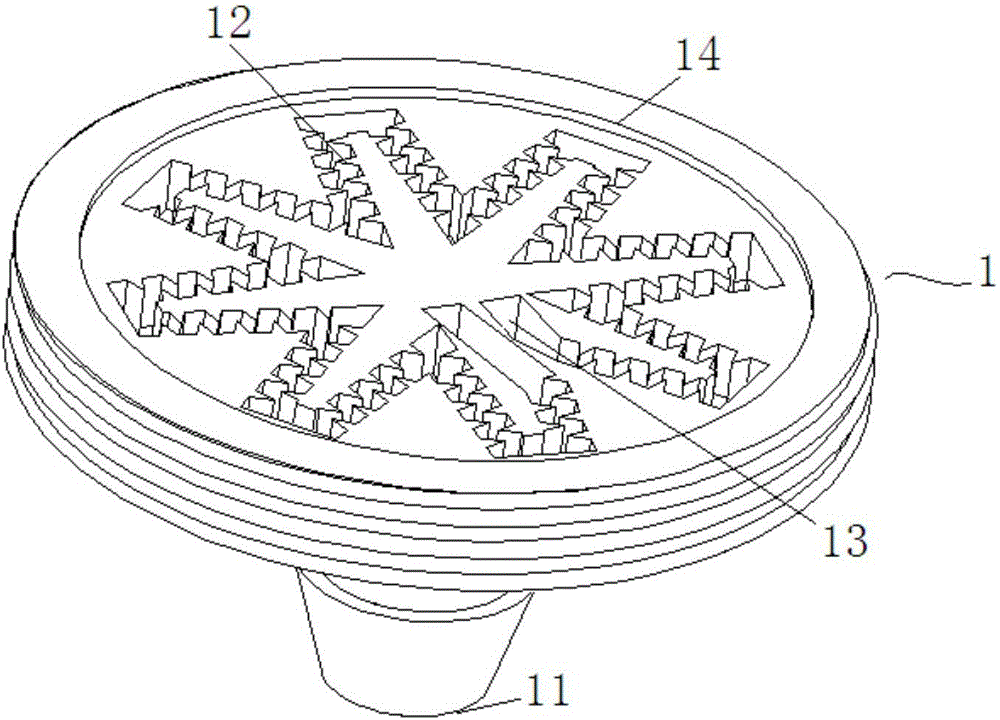

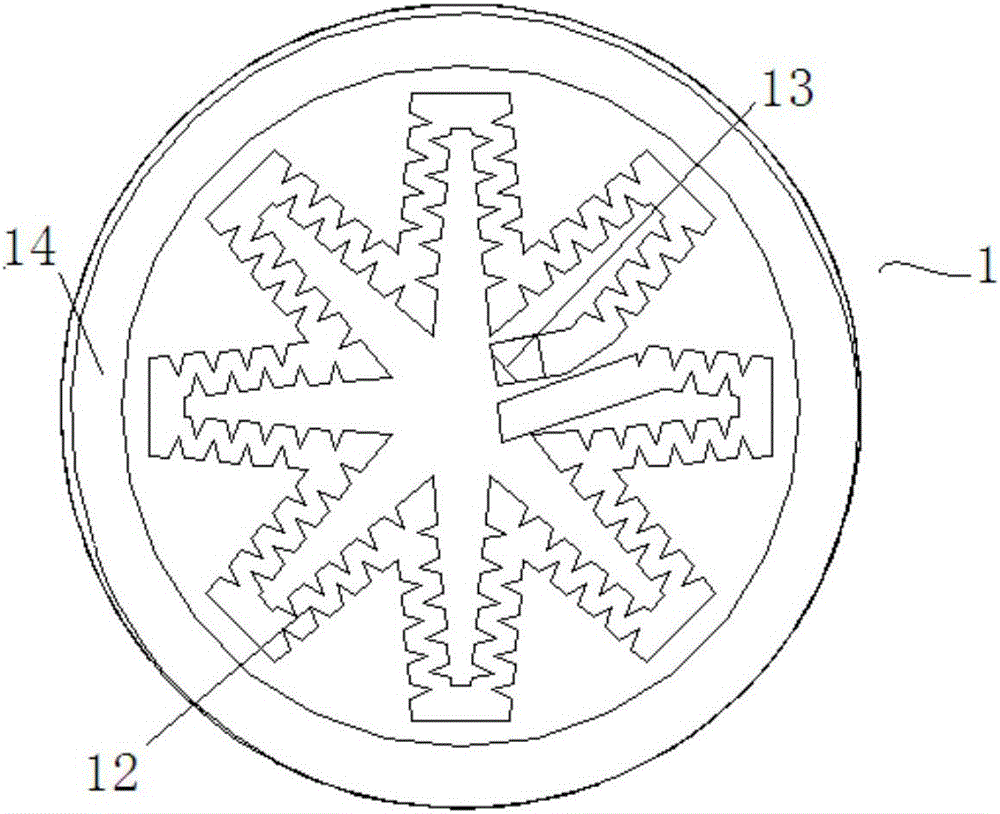

[0030] Such as figure 2 , image 3 As shown, a water inlet 11 is provided at the bottom of the inlet water guiding part 1 , and a flow channel groove 12 is opened at the top of the inlet water guiding part 1 . Such as Figure 4~6 As shown, the flow channel cover plate 2 is placed on the top of the inlet water guide part 1, and the flow channel convex body 21 matching the flow channel groove 12 is arranged at the bottom of the flow channel cover plate 2, and the flow channel convex body 21 is connected with the flow channel The channel groove 12 is slidingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com