Tea enzyme deactivation device

A greening device and tea technology, which are applied in the direction of tea treatment before extraction, can solve the problems of insufficient stirring of tea leaves, uneven temperature, poor quality of tea leaves, etc., and achieve the effects of improving greening efficiency, uniform temperature of greening, and good quality of tea leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

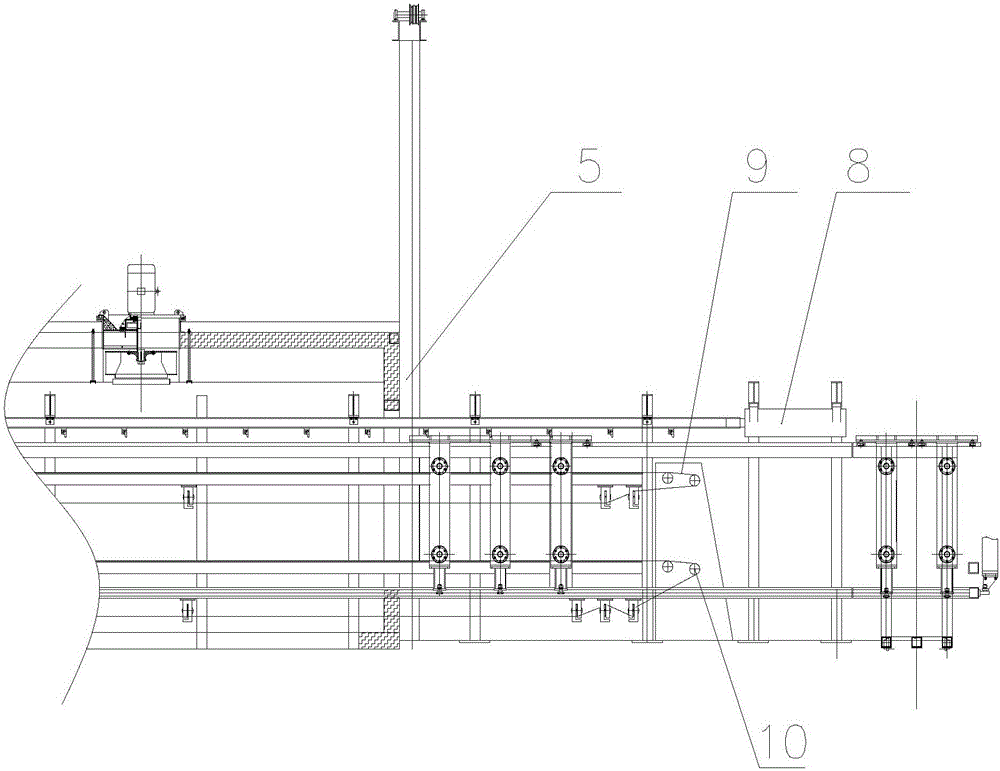

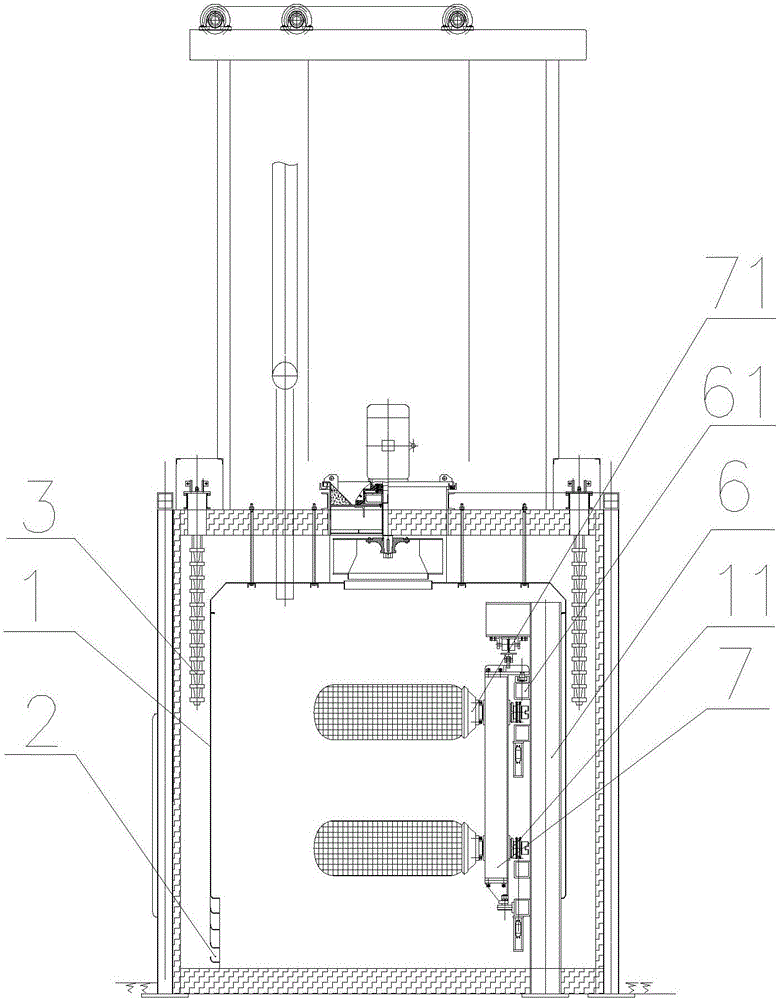

[0025] See Figure 1 to Figure 4 It is a tea-finishing device, including a heating furnace. The heating furnace is provided with a flow guide layer 1 which divides the furnace of the heating furnace into an outer zone and an inner zone. The longitudinal ends of the outer zone are sealed, so Furnace doors 5 driven by air cylinders are arranged at both longitudinal ends of the inner zone, an electric heater 3 is arranged on the upper part of the outer zone, and a fixing seat 6 is arranged in the inner zone along the longitudinal direction of the heating furnace. A sliding guide rail 61 is provided in the longitudinal direction of the furnace, and a number of movable seats 7 are slidably fitted on the sliding guide rail 61. Each movable seat 7 is respectively equipped with a fixing bottle, and the axis of the fixing bottle is perpendicular to the vertical surface where the fixing seat 6 is located. The fixation bottle includes a bottle body and a bottle cap 71. The bottle body is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com