Washing-free powdery shampoo and preparation method thereof

A non-washing, powdery technology, applied in the field of cleaning and care products, can solve the problems of not being able to wash hair frequently, affect appearance, affect mood, etc., achieve the effect of preventing itchy scalp, simple formula, and preventing dry hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

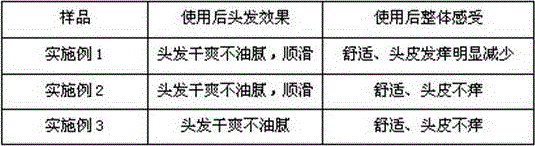

Examples

Embodiment 1

[0022] 1. Formula (by weight percentage)

[0023] Vivapur CS 9FM 18.0%

[0024] VITACEL CS 20FC 30.0%

[0025] Tapioca starch (15-20 um) 30.0%

[0026] Polymethyl methacrylate (5.8-8.5um) 15.0%

[0027] Beta-Cyclodextrin 5.0%

[0028] Capryl Glycine 0.8%

[0030] Chamomile Essential Oil 0.2%

[0031] 2. Preparation process (the experiment is based on 2kg output)

[0032] (1) Weigh each component according to the above ratio;

[0033] (2) Mix Vivapur CS 9FM, VITACEL CS 20FC, tapioca starch, polymethyl methacrylate, β-cyclodextrin, caprylyl glycine, etc. in a spray granulation dryer for 2 minutes;

[0034] (3) Put xylitol glucoside and chamomile essential oil into the grinder, add 20g of the powder mixed in step (2) to the grinder for 1 minute each time, add until 160g of powder is added, the powder at this time is completely Absorbs moisturizers and fragrances;

[0035] (4) Put the adsorbed powder in step (3) into a spray granulation dr...

Embodiment 2

[0037] 1. Formula (by weight percentage)

[0038] Vivapur CS 4FM 5.0%

[0039] VITACEL CS 20FC 27.0%

[0040] Tapioca starch 50.0%

[0041] Polymethyl methacrylate (5.8-8.5um) 10.0%

[0042] Beta-Cyclodextrin 5.0%

[0043] Capryl Glycine 1.8%

[0045] Chamomile Essential Oil 0.2%

[0046] 2. Preparation process (the experiment is based on 2kg output)

[0047] (1) Weigh each component according to the above ratio;

[0048] (2) Mix Vivapur CS 4FM, VITACEL CS 20FC, tapioca starch, polymethyl methacrylate, β-cyclodextrin, caprylyl glycine, etc. in a spray granulation dryer for 2 minutes;

[0049] (3) Put xylitol glucoside and chamomile essential oil into the grinder, add 20g of the powder mixed in step (2) to the grinder for 1 minute each time, add until 160g of powder is added, the powder at this time is completely Absorbs moisturizers and fragrances;

[0050] (4) Put the adsorbed powder in step (3) into a spray granulation dryer for mixi...

Embodiment 3

[0052] 1. Formula (by weight percentage)

[0053] Vivapur CS 9FM 5.0%

[0054] VITACEL CS 20FC 30.0%

[0055] Corn starch 45.0%

[0056] Polymethyl methacrylate (5.8-8.5um) 10.0%

[0057] Beta-cyclodextrin 7.6%

[0058] Capryl Glycine 1.2%

[0060] Lemon essential oil 0.2%

[0061] 2. Preparation process (the experiment is based on 2kg output)

[0062] (1) Weigh each component according to the above ratio;

[0063] (2) Put Vivapur CS 9FM, VITACEL CS 20FC, corn starch, polymethyl methacrylate compound, β-cyclodextrin, caprylyl glycine, etc. in a spray granulation dryer and mix for 2 minutes;

[0064](3) Put xylitol glucoside and chamomile essential oil into the grinder, add 20g of the powder mixed in step (2) to the grinder for 1 minute each time, add until 160g of powder is added, the powder at this time is completely absorbs moisturizers and fragrances;

[0065] (4) Put the adsorbed powder in step (3) into a spray granulation dryer fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com