Vertical auto-washing filter

An automatic cleaning and filter technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of affecting the life of filter elements and incomplete cleaning, so as to achieve strong self-cleaning ability and reduce filtration efficiency. , The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments of the present invention, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

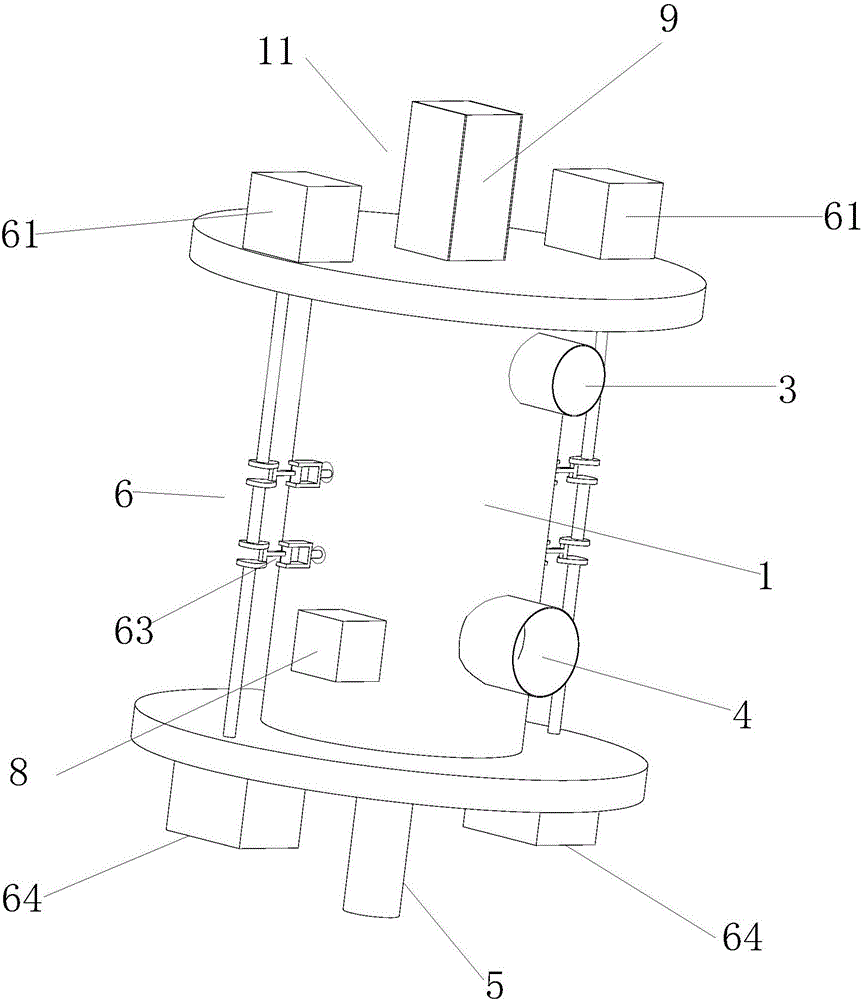

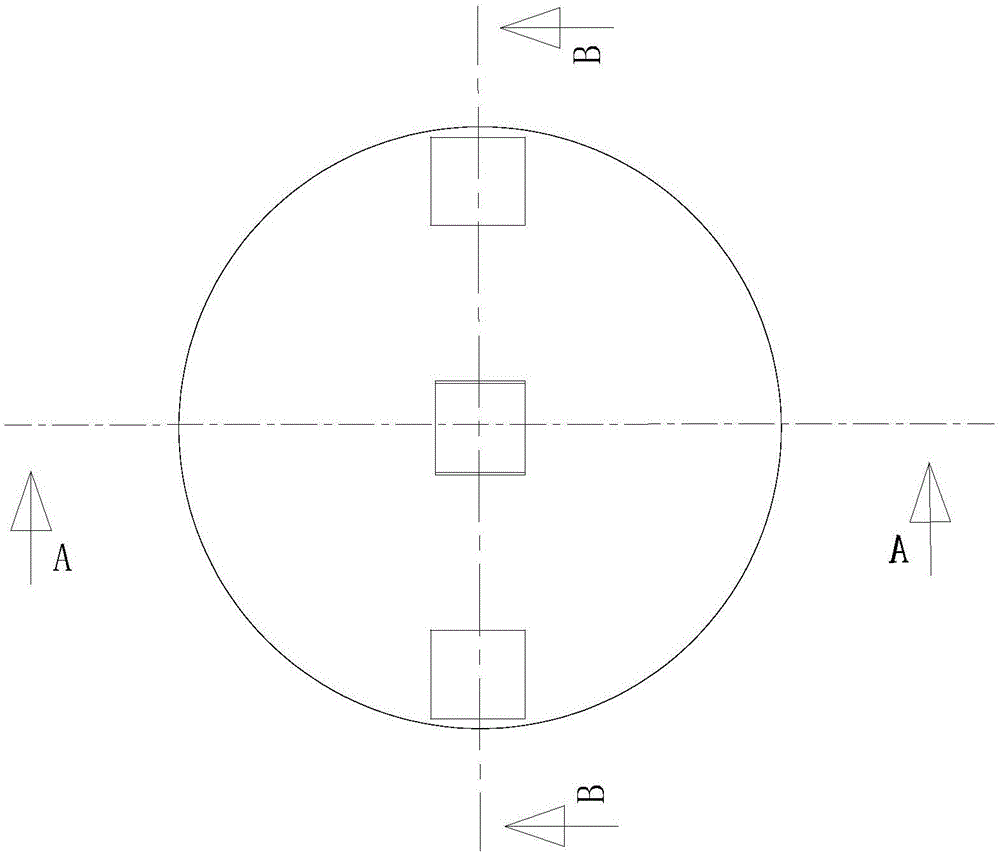

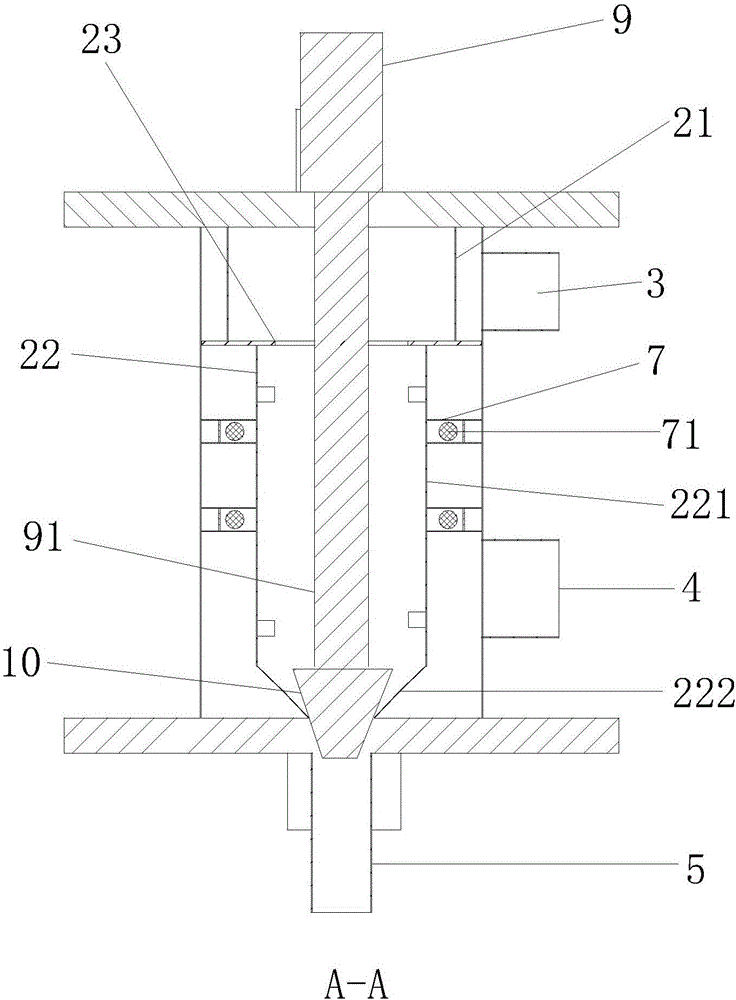

[0023] like Figures 1 to 6 A vertical self-cleaning filter is shown, which includes a shell excitation device 1 and a filter unit, the filter unit is installed inside the shell 1, and the shell 1 is provided with a water inlet 3, a water outlet 4, and a sewage outlet 5, wherein , the housing 1 is also equipped with a vibration excitation device 6, the vibration excitation device 6 includes a motor 61, a hammering mechanism 63, a bearing seat 64, the motor 61 and the bearing housing 64 are fixed on the housing 1, and the motor 61 and the bearing housing 64 A crankshaft 62 is connected between them, and the hammer mechanism 63 includes a connecting rod 631. One end of the connecting rod 631 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com