A magnetically controlled high-temperature gas segmental coupling dust removal method

A high-temperature gas and magnetic control technology, applied in the direction of separation methods, chemical instruments and methods, combined devices, etc., can solve the problems of energy saving, environmental protection, continuous high efficiency, etc., and achieve no secondary pollution, high dust concentration, safe and fast response system Effect of load change requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

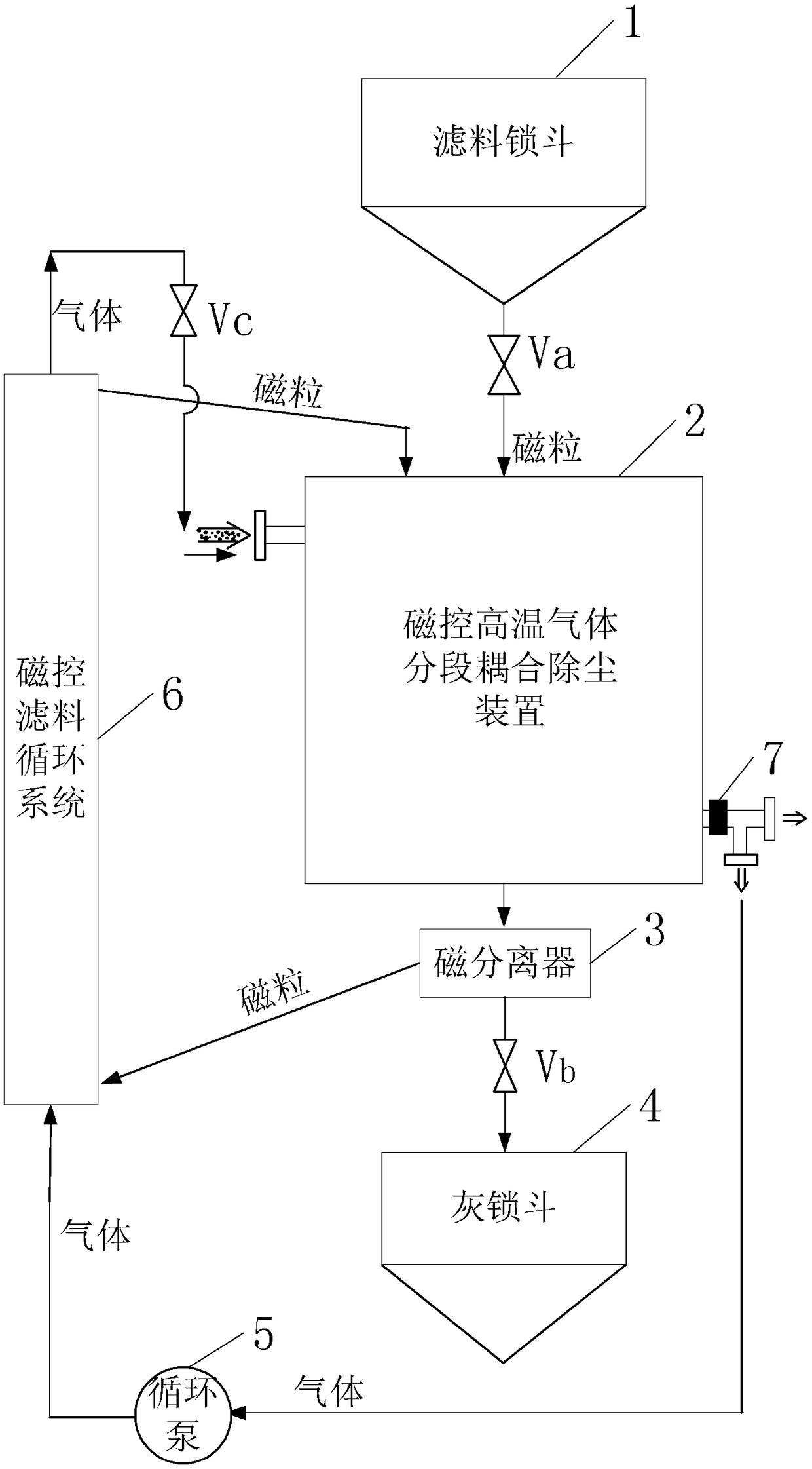

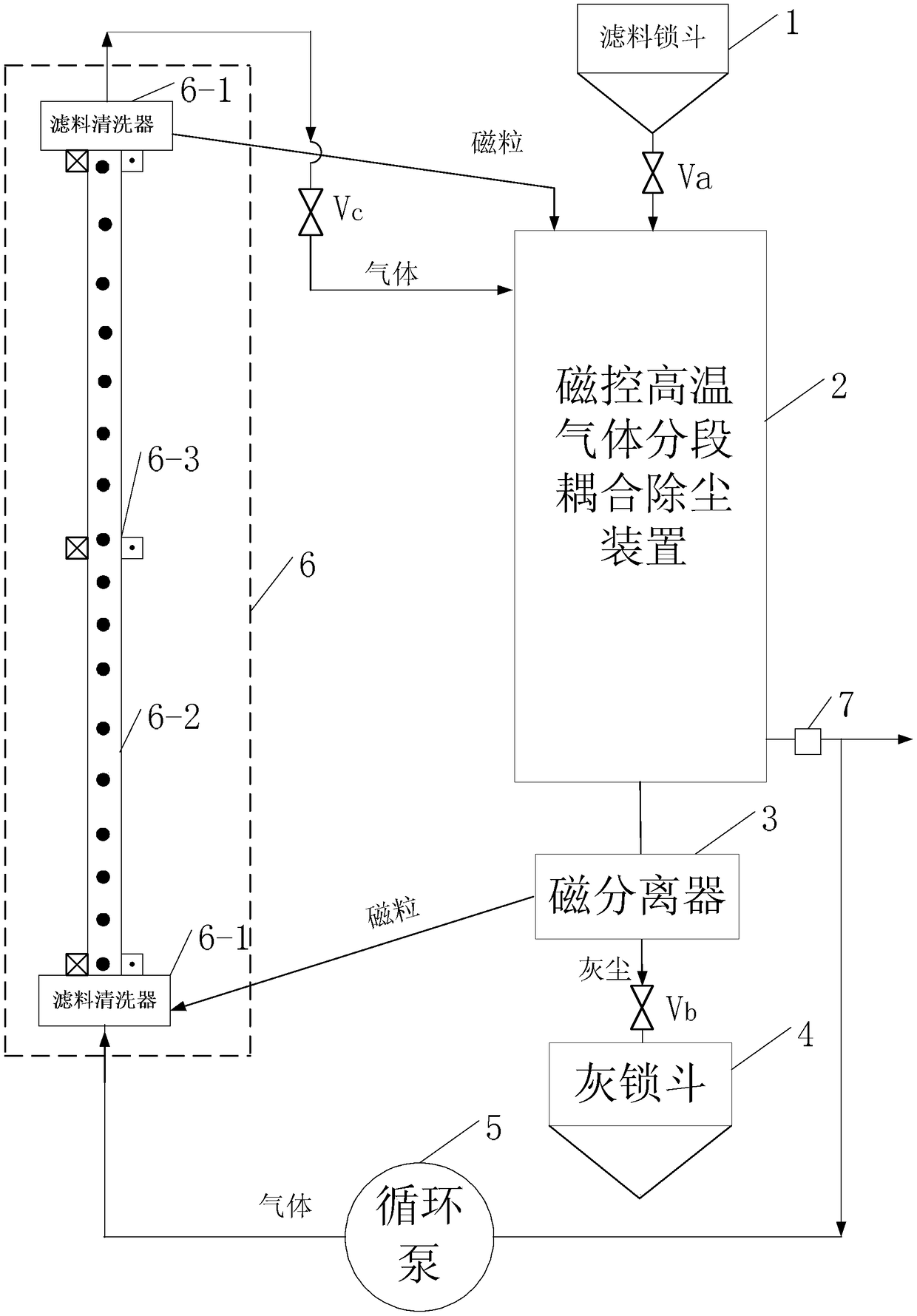

[0055] Specific implementation mode one: see figure 1 Describe this embodiment, a magnetically controlled high-temperature gas segmental coupling dedusting method described in this embodiment, the method is realized based on a segmental coupling dedusting system, and the segmental coupling dedusting system includes a filter material lock hopper 1, Magnetic control high temperature gas segmental coupling dust removal device 2, magnetic separator 3, ash lock bucket 4, circulation pump 5 and magnetic control filter material circulation system 6;

[0056] The discharge port of the filter material lock hopper 1 communicates with the feed port of the magnetically controlled high-temperature gas segmental coupling dedusting device 2, and a valve Va is provided on the discharge pipeline of the filter material lock hopper 1,

[0057] The magnetically controlled high-temperature gas segmental coupling dedusting device 2 uses the filter material particles added by the filter material loc...

specific Embodiment approach 2

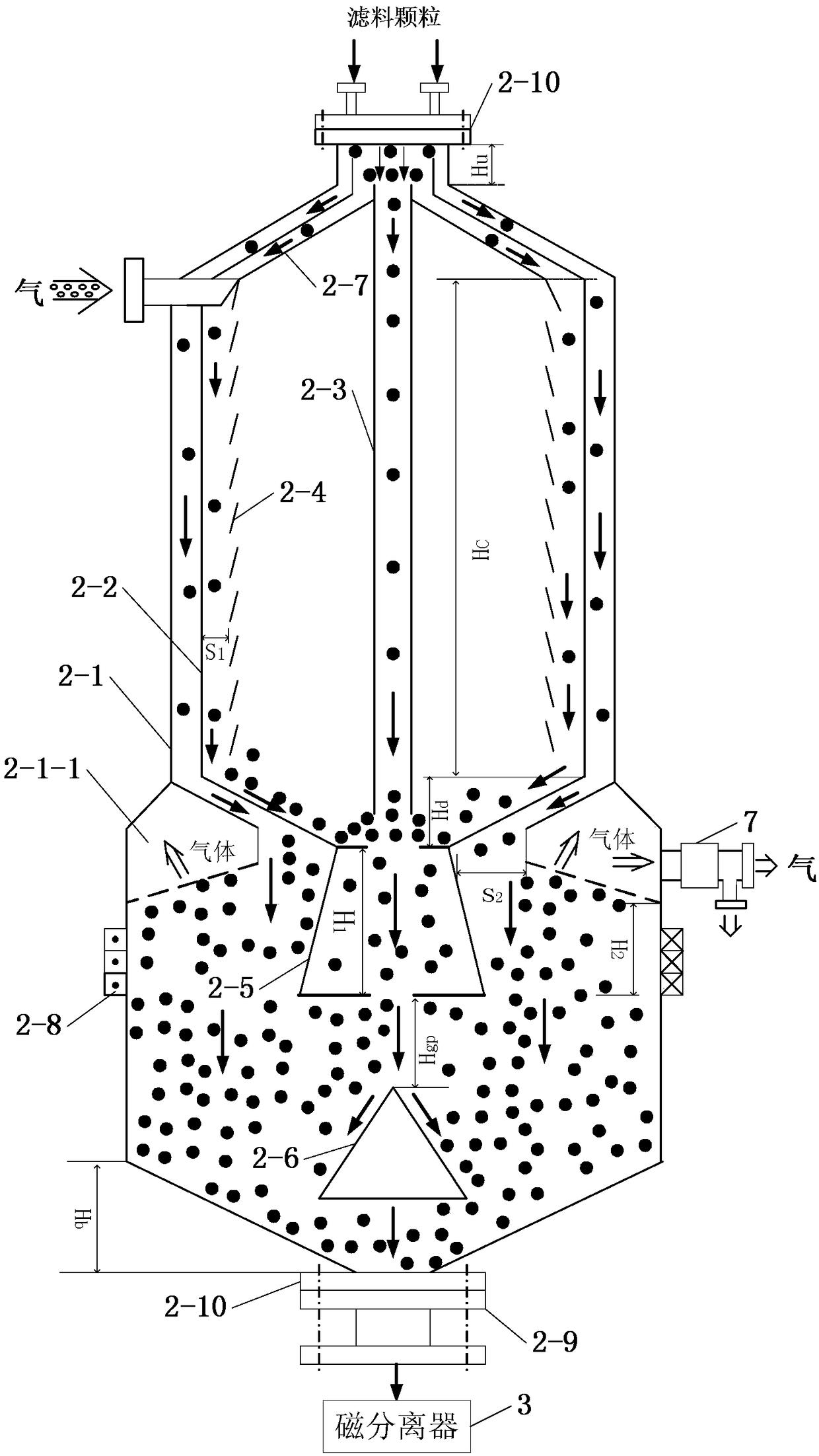

[0070] Specific implementation mode two: see figure 2 Describe this embodiment. The difference between this embodiment and the magnetically controlled high-temperature gas segmental coupling dedusting method described in the first specific embodiment is that the magnetically controlled high-temperature gas segmental coupling dedusting device 2 includes an outer shell 2-1 , inner casing 2-2, center filter particle standpipe 2-3, louver 2-4, buffer cone 2-5, diversion cone 2-6, diversion cone 2-7 and bed control coil 2-8;

[0071] The bed control coil 2-8 is wound on the lower half of the outer casing 2-1, and is used to control the porosity of the filter particles in the outer casing 2-1,

[0072] The inner shell 2-2, the buffer cone 2-5, the diversion cone 2-6 and the diversion cone 2-7 are all located in the outer shell 2-1, and the diversion cone 2-7, the inner The casing 2-2 and the outer casing 2-1 are nested sequentially from the inside to the outside, and there is a c...

specific Embodiment approach 3

[0080] Specific implementation mode three: see figure 1 Or 2 illustrates this embodiment, the difference between this embodiment and a magnetically controlled high-temperature gas segmental coupling dedusting method described in the second embodiment is that the filter material particles have three moving paths:

[0081] First, the filter material particles entering from the channel between the inner shell 2-2 and the outer shell 2-1 move downward and accumulate at the bottom of the outer shell 2-1,

[0082] Second, the filter material particles entering from the channel between the inner shell 2-2 and the diversion cone 2-7 move downward, and flow through the channel between the inner shell 2-2 and the louver 2-4 to the inner shell 2 -2 bottom, so that after passing through the buffer cone 2-5, it is accumulated at the bottom of the outer shell 2-1 after diverted by the diversion cone 2-6,

[0083]Third, the filter material particles entering from the central filter material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com