Uranyl nitrate hexahydrate feeding device for fluidized bed denitration technology

A technology of uranyl nitrate feed solution and uranyl nitrate, which is applied in the directions of feeding device, chemical instrument and method, chemical/physical process, etc., to achieve the effects of stable operation, convenient control and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

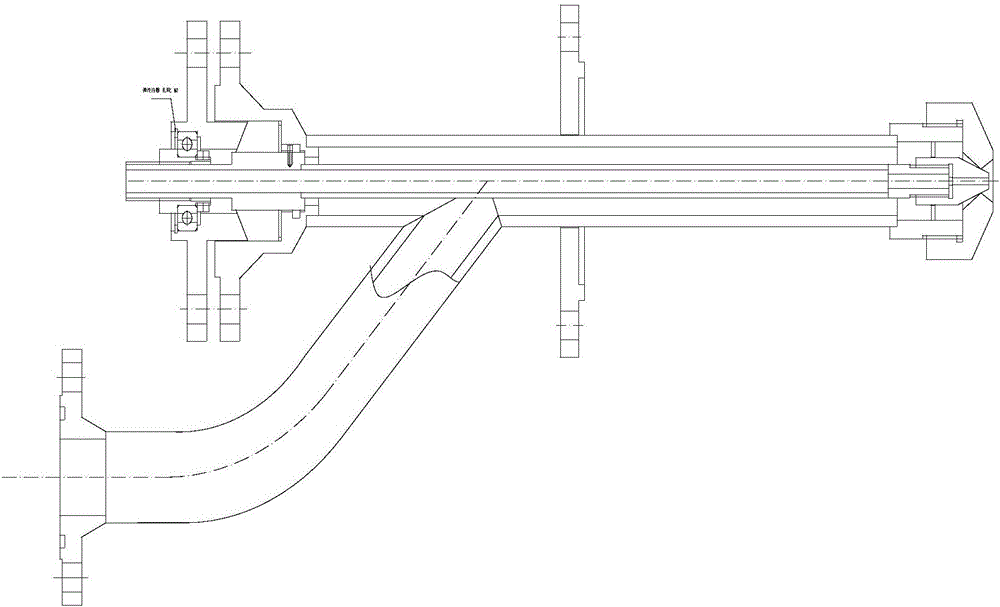

[0062] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0063] Such as figure 1 As shown, the present invention is a uranyl nitrate feeding device for fluidized bed denitrification technology, specifically an atomizing nozzle structure, wherein:

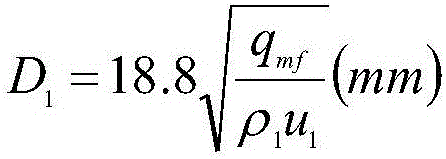

[0064] 1. Determine the uranyl nitrate feed liquid conduit

[0065] Inner diameter D1 of uranyl nitrate feed liquid conduit of atomizing nozzle:

[0066]

[0067] Where qmf: mass flow rate of feed liquid, kg / h;

[0068] ρ1: material liquid density;

[0069] u1: The flow rate of the feed liquid in the conduit, which is determined according to the capacity of different furnace types;

[0070] Uranyl nitrate liquid conduit outer diameter D10:

[0071] D10=D1+2δ1, δ1 is the wall thickness of the uranyl nitrate feed liquid conduit;

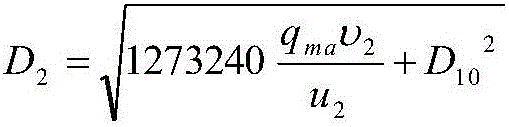

[0072] 2. Atomizing air duct

[0073] Inner diameter of atomizing air duct D 2 :

[0074] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com