A kind of photocatalyst powder and preparation method thereof

A technology of photocatalyst and preparation process, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problems of poor weather resistance and poor adhesion, which is not easy to achieve Abrasion and drop, strong adhesion, effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A preparation process of photocatalyst powder, comprising the following steps:

[0049] 1) Put the formula amount of titanyl sulfate, metatitanic acid and composition A into the mixer, and stir evenly to obtain the first mixture;

[0050] 2) Put the basic oxide solution of the formula into the mixer, mix with the first mixture, and stir for 8-12min to obtain the second mixture, the second mixture is a solid-liquid mixture;

[0051] 3) performing solid-liquid separation on the second mixture to obtain a solid mixture and a liquid mixture;

[0052] 4) taking the solid mixture and drying it in an environment below 100-150°C to obtain the first semi-finished product;

[0053] 5) Calcining the first semi-finished product to obtain a second semi-finished product;

[0054] 6) Grinding the second semi-finished product to obtain the photocatalyst powder.

[0055] As a preferred scheme, in step 1), the rotating speed of the mixer is 1200r / min, and the stirring time is 25-35min...

Embodiment 1

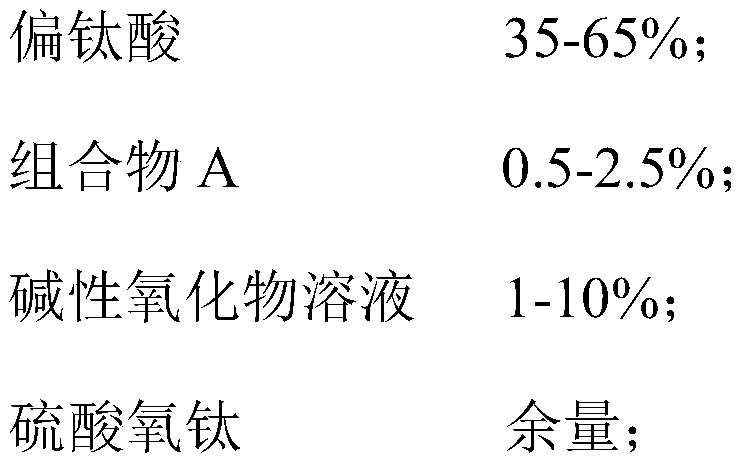

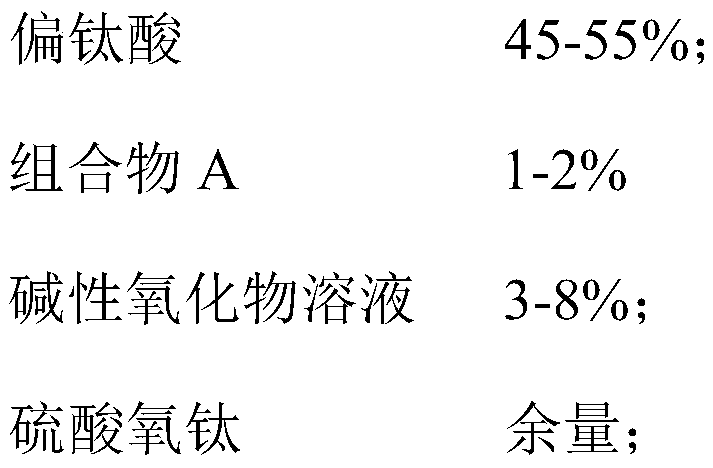

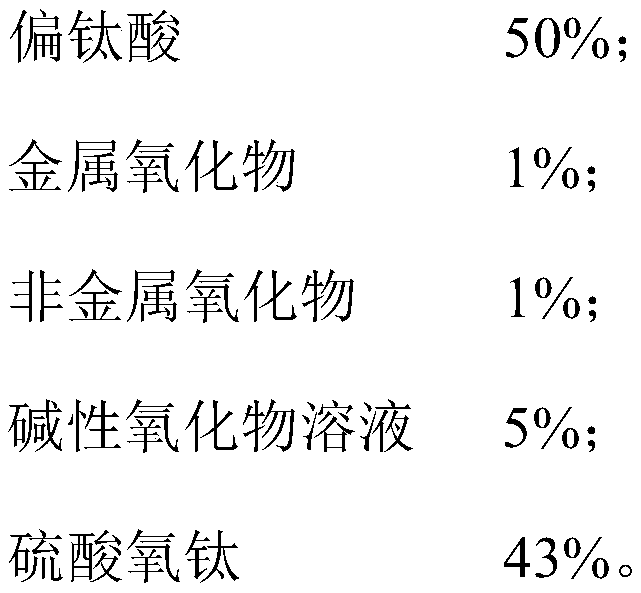

[0057] A photocatalyst powder is prepared from metatitanic acid, composition A (metal oxide and non-metal oxide), alkaline oxide solution, titanyl sulfate, and the weight percentages of the above-mentioned components are shown in Table 1. The photocatalyst powder is prepared according to the following steps:

[0058] 1) Put the formula quantity of titanyl sulfate, metatitanic acid and composition A into the mixer, set the rotation speed of the mixer to 1200r / min, and the stirring time to 30min, after stirring evenly, the first mixture is obtained;

[0059]2) Put the basic oxide solution of the formulated amount into the mixer, mix with the first mixture, and stir for 10 minutes to obtain a second mixture, which is a solid-liquid mixture;

[0060] 3) performing solid-liquid separation on the second mixture to obtain a solid mixture and a liquid mixture;

[0061] 4) Take the solid mixture, place it in an environment below 150°C, and dry it for 1 hour to obtain the first semi-fi...

Embodiment 2

[0065] A photocatalyst powder is prepared from metatitanic acid, composition A (metal oxide and non-metal oxide), alkaline oxide solution, titanyl sulfate, and the weight percentages of the above-mentioned components are shown in Table 1. The photocatalyst powder is prepared according to the following steps:

[0066] 1) Put the formula quantity of titanyl sulfate, metatitanic acid and composition A into the mixer, set the rotation speed of the mixer to 1200r / min, and the stirring time to 25min, after stirring evenly, the first mixture is obtained;

[0067] 2) Put the basic oxide solution of the formulated amount into the mixer, mix with the first mixture, and stir for 12 minutes to obtain a second mixture, which is a solid-liquid mixture;

[0068] 3) performing solid-liquid separation on the second mixture to obtain a solid mixture and a liquid mixture;

[0069] 4) Take the solid mixture, place it in an environment below 150°C, and dry it for 0.7h to obtain the first semi-fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com