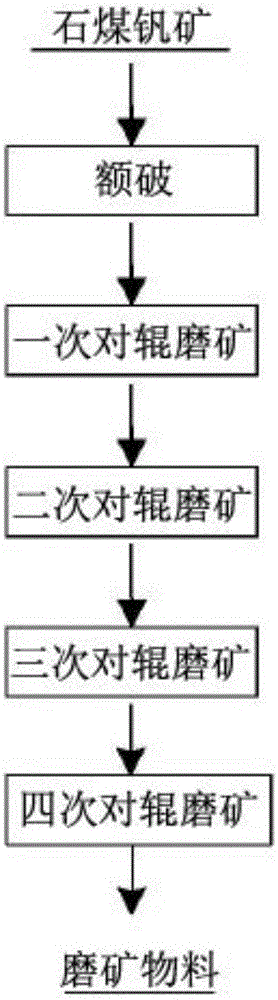

Ore grinding method for stone coal vanadium ore

A stone coal vanadium and ore grinding technology, which is applied in the direction of grain processing, etc., can solve the problems of long grinding process, complicated operation, and high production cost, and achieve the effects of reducing the grinding process, simple operation, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The stone coal vanadium ore is sent to the frontal crusher for frontal crushing to obtain a frontal crushing material with a particle size of less than 100mm; wherein, the stone coal vanadium ore contains 9% water and 18% of the material with a particle size smaller than 2mm.

[0047] Use the double-roll machine to carry out four times of double-roller grinding on the crushed material in turn. In the first double-roller grinding, the distance between the double-rollers of the double-roller machine is adjusted to 23mm, and the processing capacity is set to 23t / h to obtain the particle size For the first grinding material smaller than 25mm, the content of the material with a particle size smaller than 2mm is 29%; for the second roller grinding, adjust the roller spacing of the roller machine to 3.5mm, and set the processing capacity to 23t / h, to obtain the second grinding material with a particle size of less than 5mm, wherein the content of the material with a particle s...

Embodiment 2

[0049] The stone coal vanadium ore is sent to the frontal crusher for frontal crushing, and the crushed material with a particle size of less than 100 mm is obtained; wherein, the water content of the stone coal vanadium ore is 11%, and the material content of the particle size is less than 2mm is 20%.

[0050] Use the double-roller machine to carry out four double-roller grinding on the broken material in turn. In the first double-roller grinding, adjust the roller spacing of the double-roller machine to 22mm, set the processing capacity to 27t / h, and obtain the particle size For the first grinding material smaller than 25mm, the content of the material with a particle size smaller than 2mm is 30%; for the second roller grinding, adjust the roller spacing of the roller machine to 3.3mm, and set the processing capacity to 27t / h, to obtain the second grinding material with a particle size of less than 5mm, wherein the content of the material with a particle size of less than 2m...

Embodiment 3

[0052] The stone coal vanadium ore is sent to the frontal crusher for frontal crushing to obtain a frontal crushing material with a particle size of less than 100mm; wherein, the stone coal vanadium ore contains 13% of water and 22% of the material with a particle size of less than 2mm.

[0053] Use the double-roll machine to carry out four double-roller grinding on the crushed material in turn. In the first double-roller grinding, adjust the distance between the double-rollers to 20mm, set the processing capacity to 25t / h, and obtain the particle size For the first grinding material less than 25mm, the content of the material whose particle size is less than 2mm is 32%; for the second roller grinding, adjust the roller spacing of the roller machine to 3.0mm, and set the processing capacity to 25t / h, to obtain the second grinding material with a particle size of less than 5mm, wherein the content of the material with a particle size of less than 2mm is 50%; during the third ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap