Cyclone acoustic wave generating device

A sound wave generation and cyclone technology, applied in lighting and heating equipment, fluids using vibration, etc., can solve the problems of high equipment failure rate, large equipment installation, high production cost, high operating efficiency, convenient installation and debugging, and reduce The effect of production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

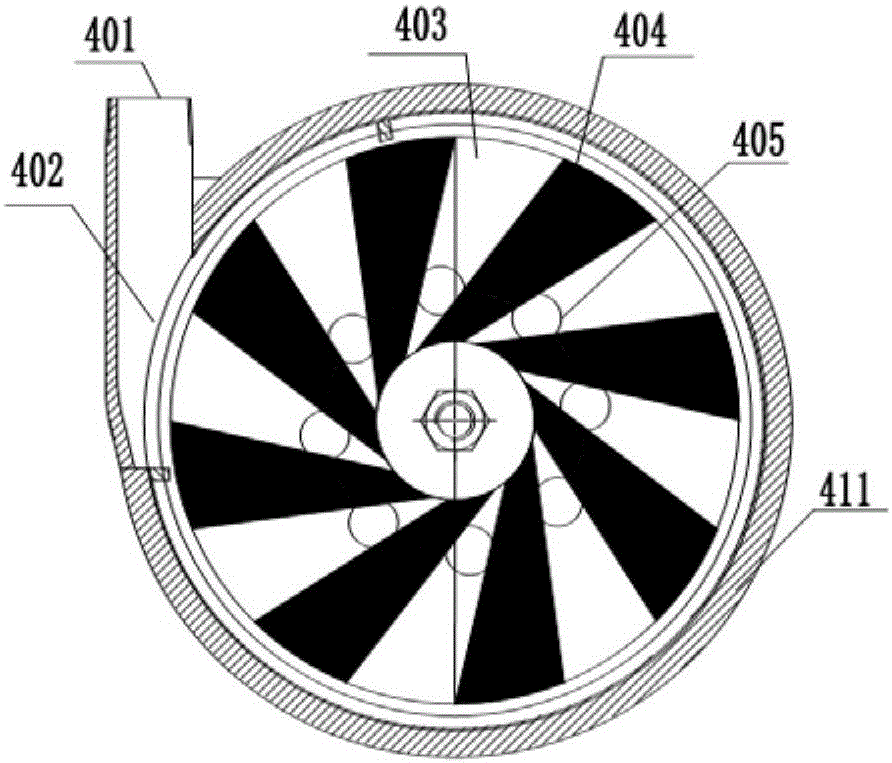

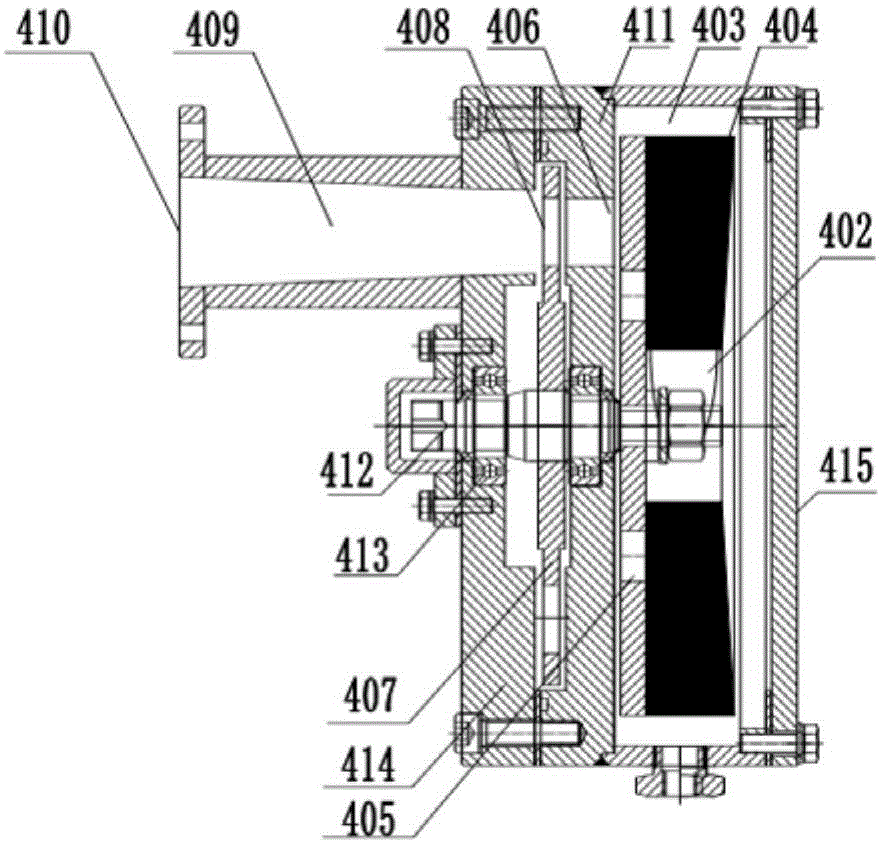

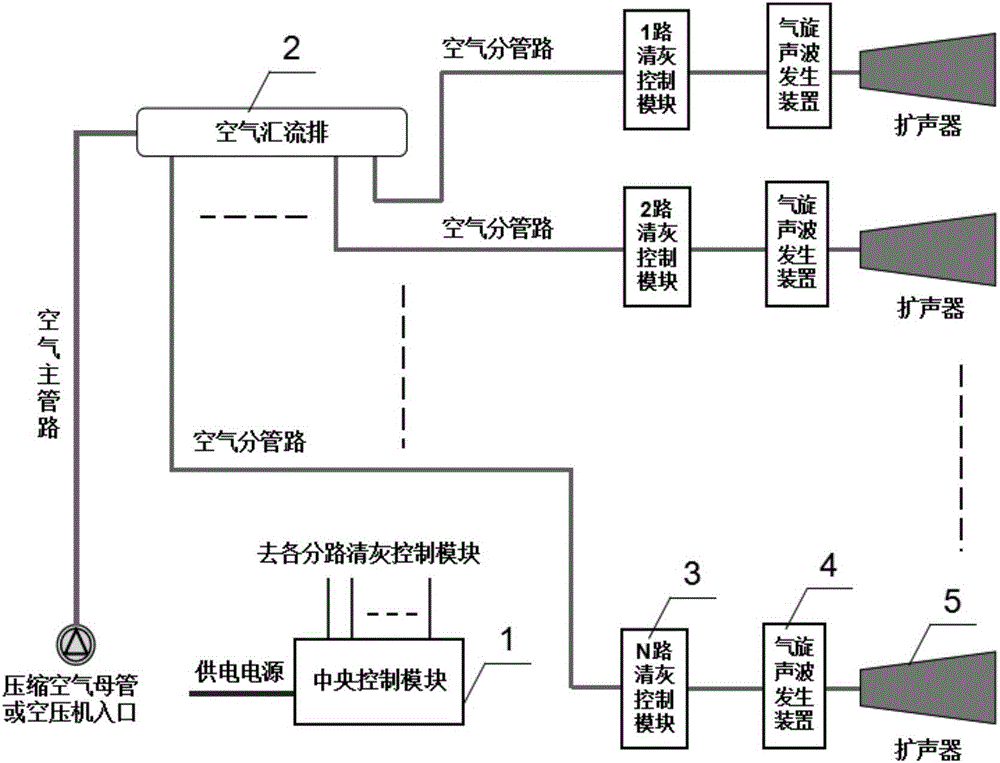

[0039] Such as figure 1 and figure 2 As shown, a cyclonic sound wave generating device provided by the embodiment of the present invention includes a device body 411, a front cover 414, an air inlet 402, a rear cover 415, a rotor 412, a bearing 413, a rotating blisk 404, an audio orifice disc 407 and Sound conduit 409; the device body 411 and the rear cover 415 form a main air chamber 403, the main air chamber 403 communicates with one end of the air inlet 402, and the other end of the air inlet 402 is the The air inlet 401 of the cyclonic sound wave generating device 4; the rotating blade disc 404 is arranged in the main air chamber 403, and the rotating blade disc 404 is provided with air guide holes 405; the audio hole disc 407 is arranged in the In the space formed by the device body 411 and the front cover 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com