Decorative strip supply method and transverse die-cutting part suitable for same

A supply method and technology for decorative strips, applied in the direction of object supply, transportation and packaging, metal processing, etc., can solve the problems of inconvenient use, complex design, accumulated errors, etc., and achieve the effect of reducing process steps, simplifying the process, and being easy to debug.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

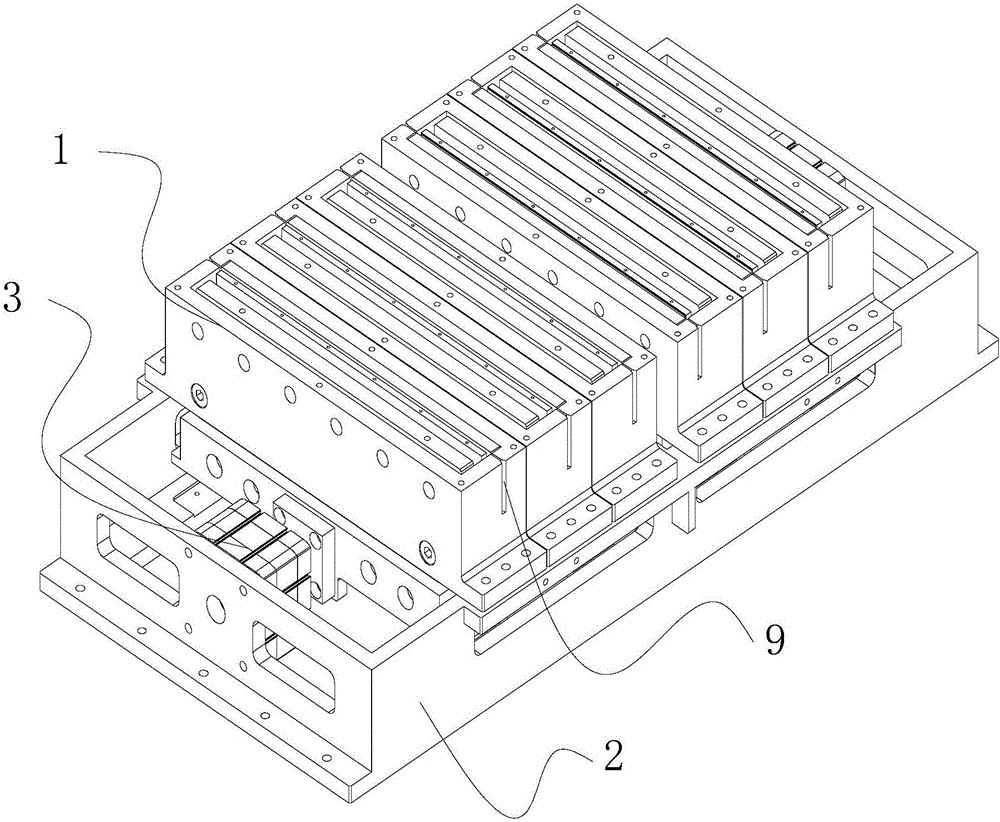

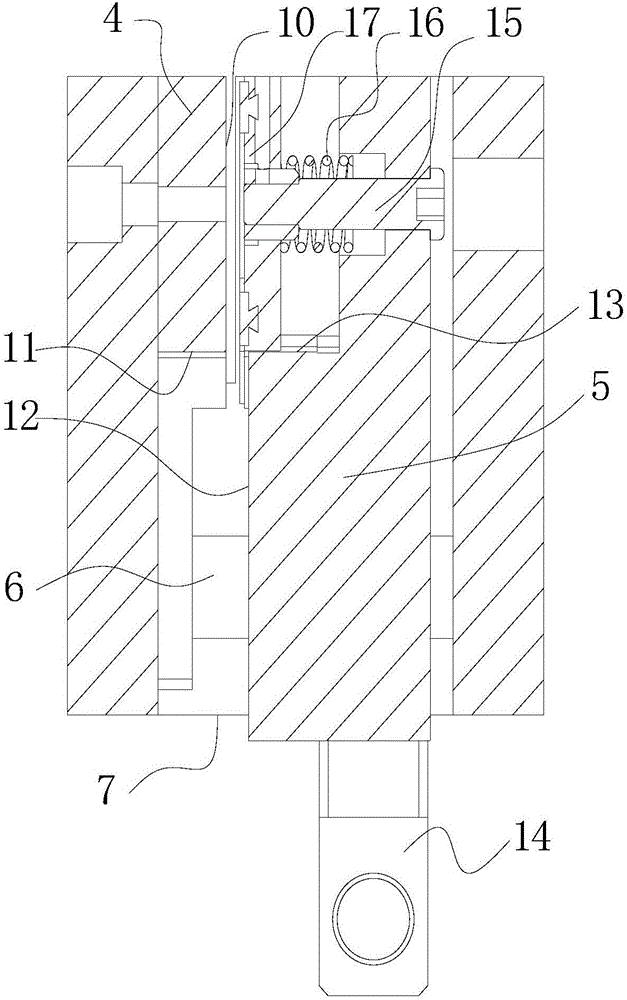

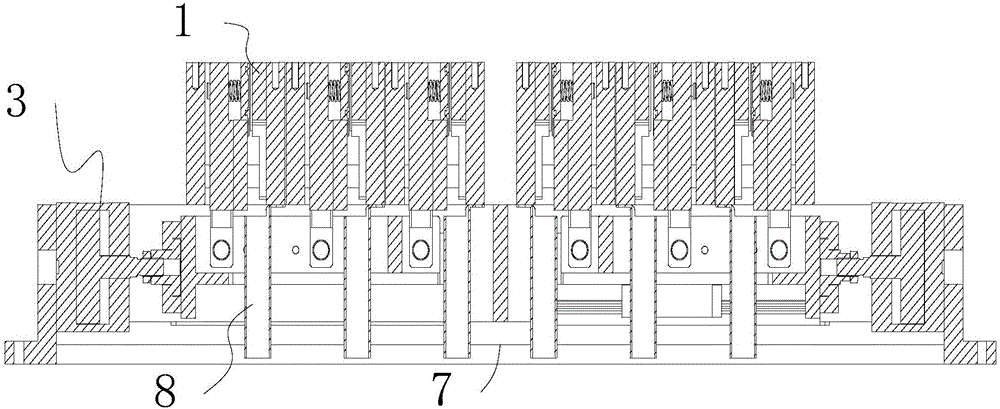

[0029] The first embodiment of the present invention.

[0030] The decorative strip supply device is provided with a decorative sheet output part, a longitudinal cutting part, a transverse die-cutting part, a winding aligning part, and a transverse cutting part. The decorative sheet output part, the longitudinal cutting part, the transverse die-cutting part, the winding aligning part, and the transverse truncating and cutting part are fixedly installed on the frame in a straight arrangement.

[0031] The decorative sheet output part is provided with a roller around which the decorative sheet is wound. The movable roller shaft is mainly installed on the frame, and the roller shaft can freely rotate on the frame. The longitudinal cutting unit includes cutters and guide rollers. Both the cutter and the guide rollers are installed on the frame, the cutters are arranged at equal intervals in the same straight line, the guide rollers are movably installed on the frame, and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com