Door relief filling process

A technology of embossment and door body, which is applied in the field of door body embossment filling technology, which can solve the problems of easy cracking of bamboo door core board and cutting damage of knives, and achieve the effect of rich styles and various shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

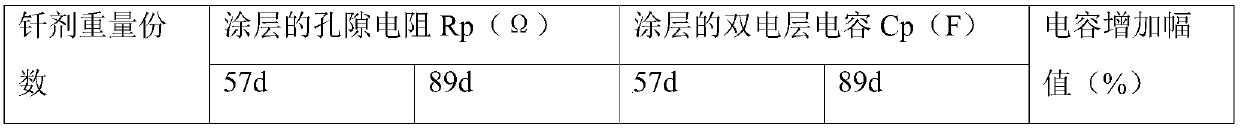

[0016] The reference signs in the drawings of the description include: inner panel 1 , outer panel 2 , main body door frame 3 , feed slot hole 4 .

[0017] The embodiment is basically as attached figure 1 As shown: the door body includes an inner panel 1, an outer panel 2 and a main door frame 3 sandwiched between the inner and outer panels. The inner panel 1 and the outer panel 2 are provided with embossed concave-convex parts. The concave-convex part 6 is a display There are a variety of embossed patterns, the inner panel 1 and the outer panel 2 are coated with water-soluble primer and UV surface coating, and several feeding slot holes 4 are arranged on the upper end of the main door frame 3, through which the feeding slot holes 4. Add modifier, filler, water, talc material and composite material synthesized by sawdust into the main body door frame 3.

[0018] A more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com