Printing head structure of 3D printer

A printing head and guide mechanism technology, applied in the field of additive manufacturing, can solve the problems affecting the performance and life of the nozzle structure of the printing head, the temperature field affecting the effective extrusion of the feeding material, and the length of the guide tube, etc., to achieve a reasonable temperature distribution, The effect of prolonging the service life and increasing the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

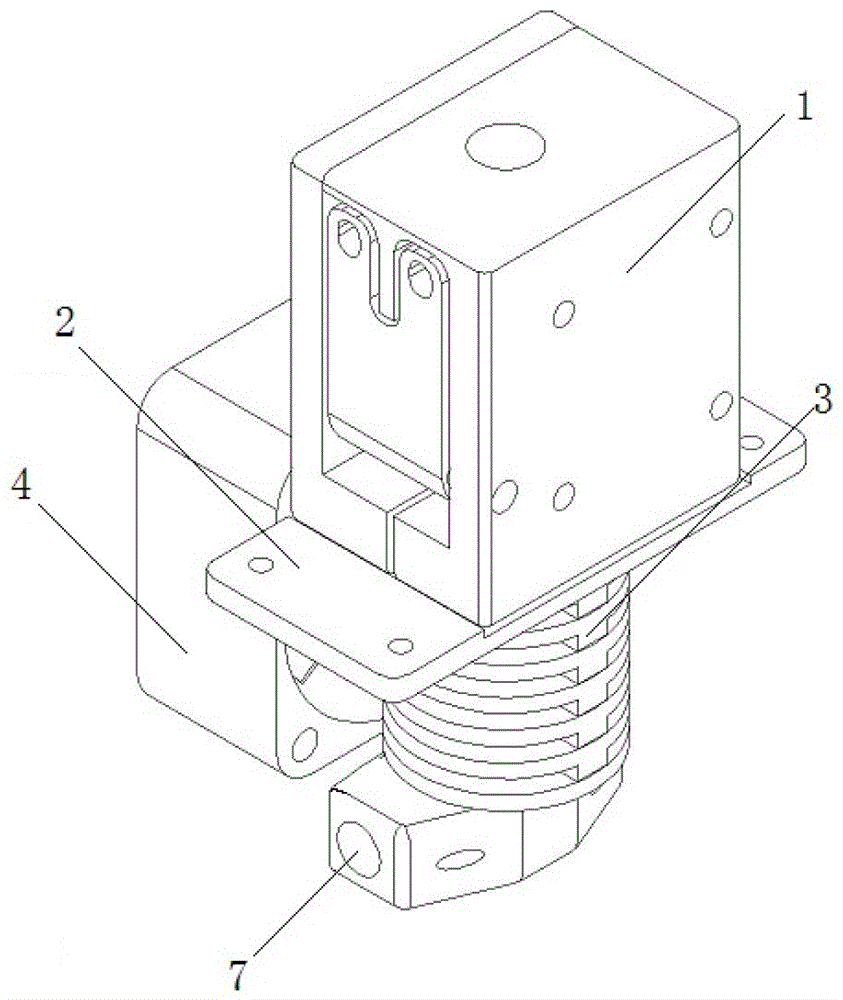

[0015] figure 1 It is a structural representation of the present invention. As shown in the figure, the entire print head structure includes a feeding mechanism 1, a mounting plate 2, a printing head mechanism 3, and a fan 4. The feeding mechanism 1 is installed on the mounting plate 2, with a feeding hole on the top and a discharge hole on the bottom. hole, the mounting plate 2 has a feeding hole; the fan 4 is installed on the side of the print head mechanism 3.

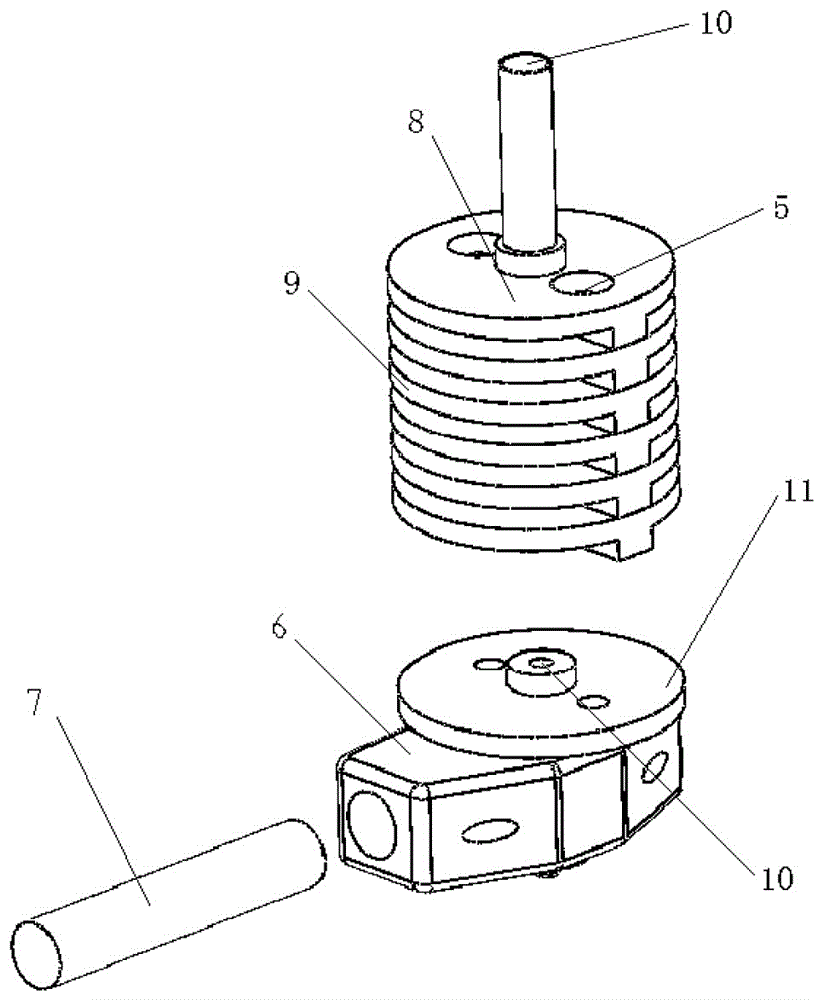

[0016] figure 2 It is a schematic diagram of the exploded structure of the printing head mechanism of the present invention. The print head mechanism 3 shown in the figure includes a heat dissipation guide mechanism, a print head nozzle 6 and a heating rod 7, and the heat dissipation guide mechanism is composed of a feeding connection plate 8, a plurality of heat sinks 9 and an installation platform 11 placed on the print head nozzle 6 , the feeding connection plate 9 located at the uppermost end of the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com