Clamping assembly for new energy vehicle power batteries

A new energy vehicle and power battery technology, applied in power units, electric power units, vehicle maintenance, etc., can solve the problems of high management and assembly costs, low progress efficiency, slow assembly speed, etc., to promote intelligent automatic upgrades The effect of transformation, reduced assembly time, reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

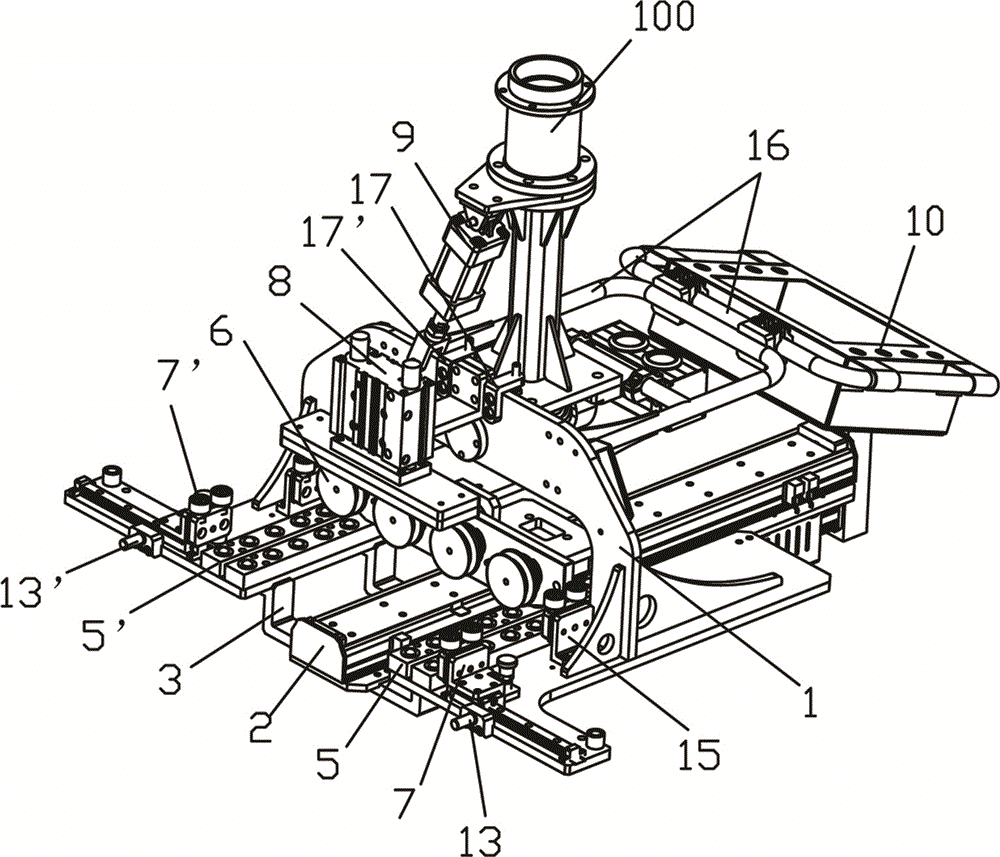

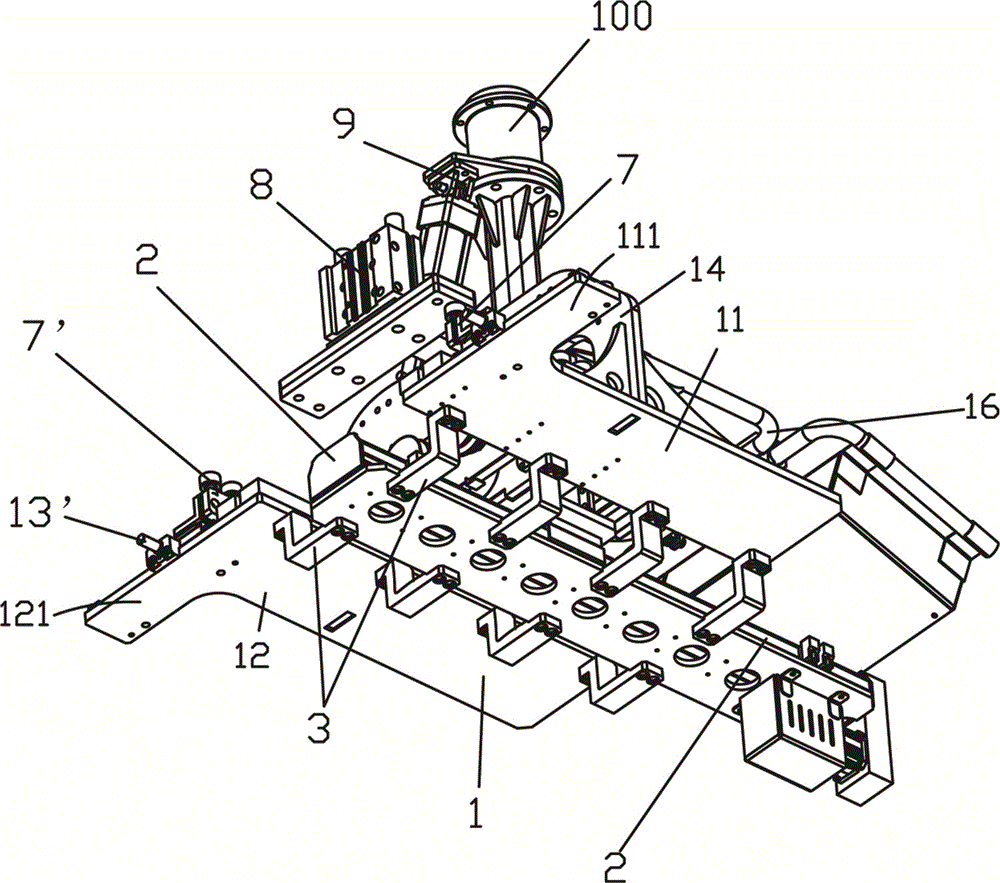

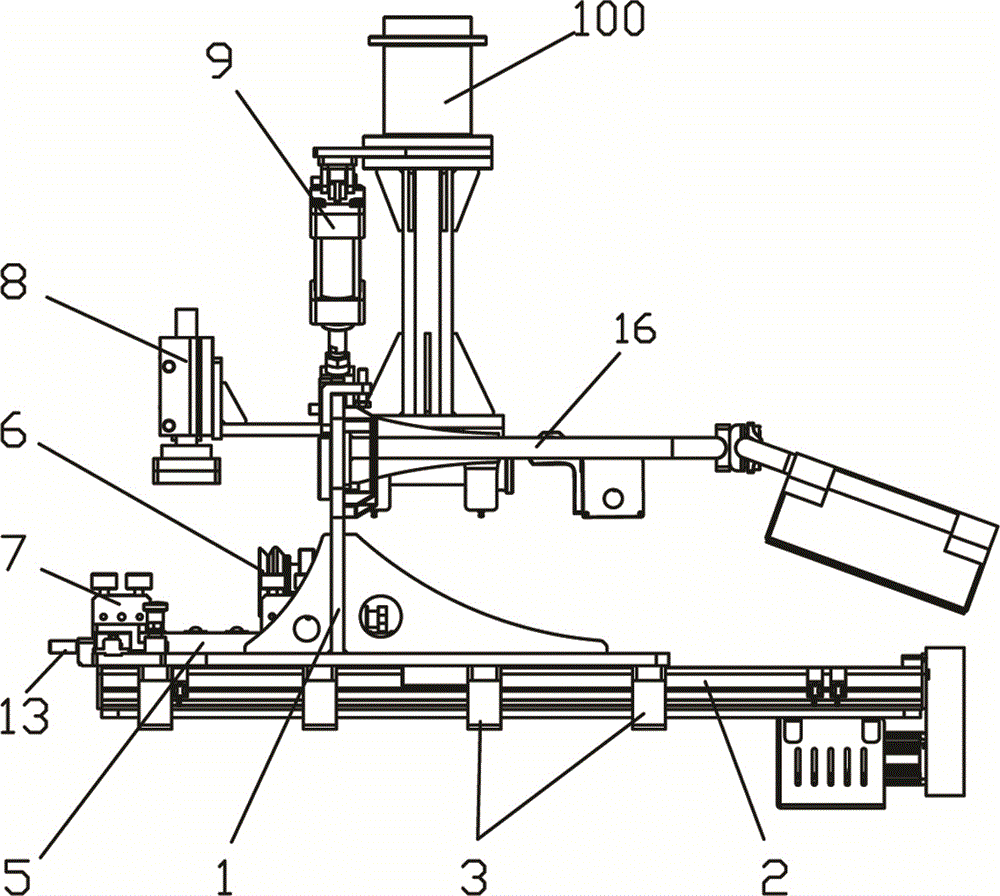

[0026] see Figure 1 to Figure 6 , a clamping assembly of a new energy vehicle power battery of the present invention, which includes,

[0027] Basic framework 1, including,

[0028] The two substrates 11, 12 are arranged in an L-shape, and their bending parts 111, 121 are arranged on both sides; the front faces of the two substrates 11, 12 are symmetrically provided with a positioning column 13, 13';

[0029] A substrate connection plate 14, in an inverted U shape, its two ends are vertically connected to the middle of the upper end surfaces of the two substrates 11, 12, and a through hole 141 is provided in the middle of the substrate connection plate 14;

[0030] The linear slide table 2 is arranged between the two base plates 11 and 12 of the basic frame 1. The linear slide table 2 is connected to the two base plates 11 and 12 on both sides through a plurality of connecting rods 3; Block; Position sensors 4, 4' are set on the side of the linear slide table front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com