An automatic edge wrapping device for a daylighting panel production line

A technology of an edge wrapping device and a lighting panel, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of the reduction of the service life of the lighting panel, the health hazards of the staff, and the reduction of the strength of the incision, so as to achieve a good installation environment, Ease of operation and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

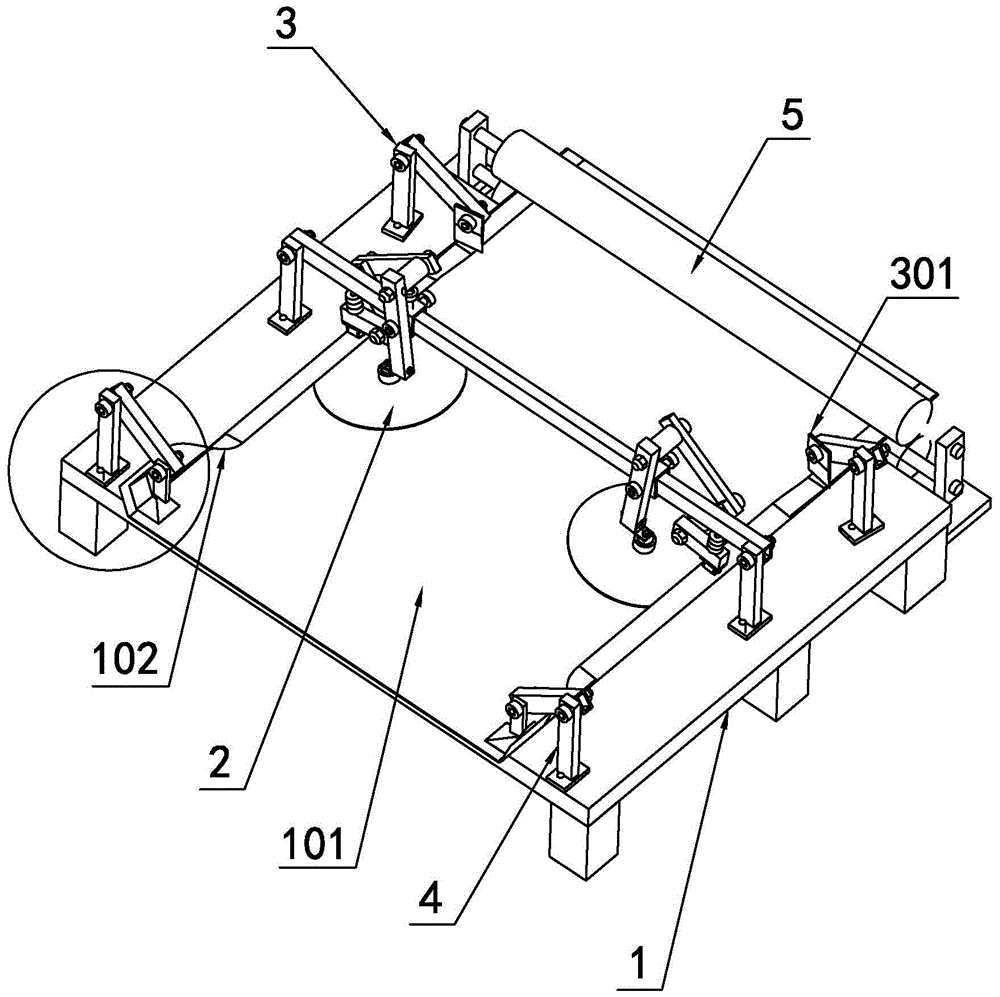

[0039] Such as Figure 1-5 As shown, an automatic edge wrapping device for a lighting board production line includes a working platform 1, a shaping mechanism 2, a scraping mechanism 3, and an extrusion roller 5. The lower part of the working platform 1 is provided with supporting feet, and the upper part of the working platform 1 is provided with lighting. Board 101, edge-wrapping belts 102 are arranged on both sides of the daylighting board 101, and a shaping mechanism 2 is arranged on the upper part of the edge-wrapping belt 102.

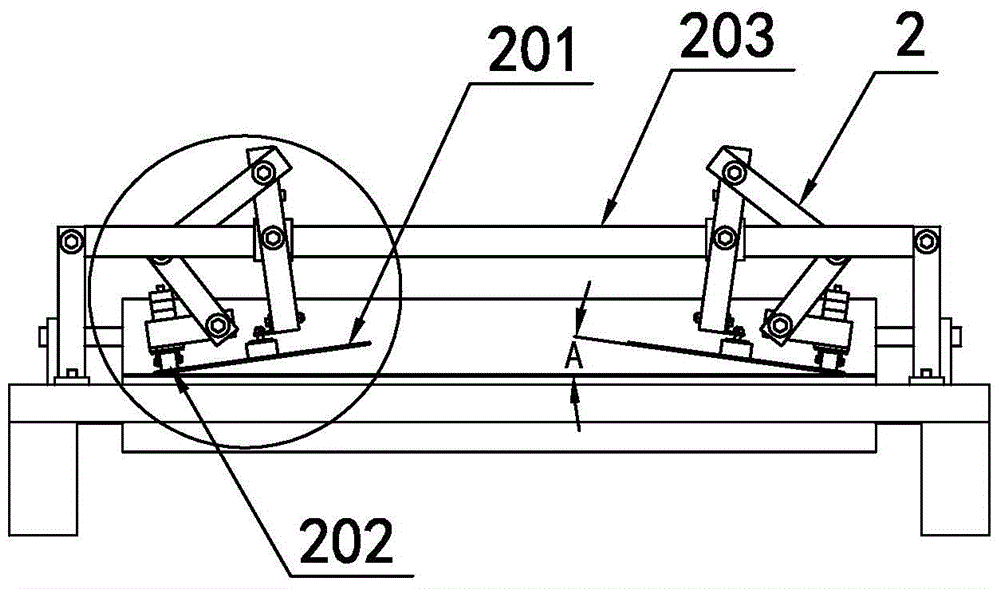

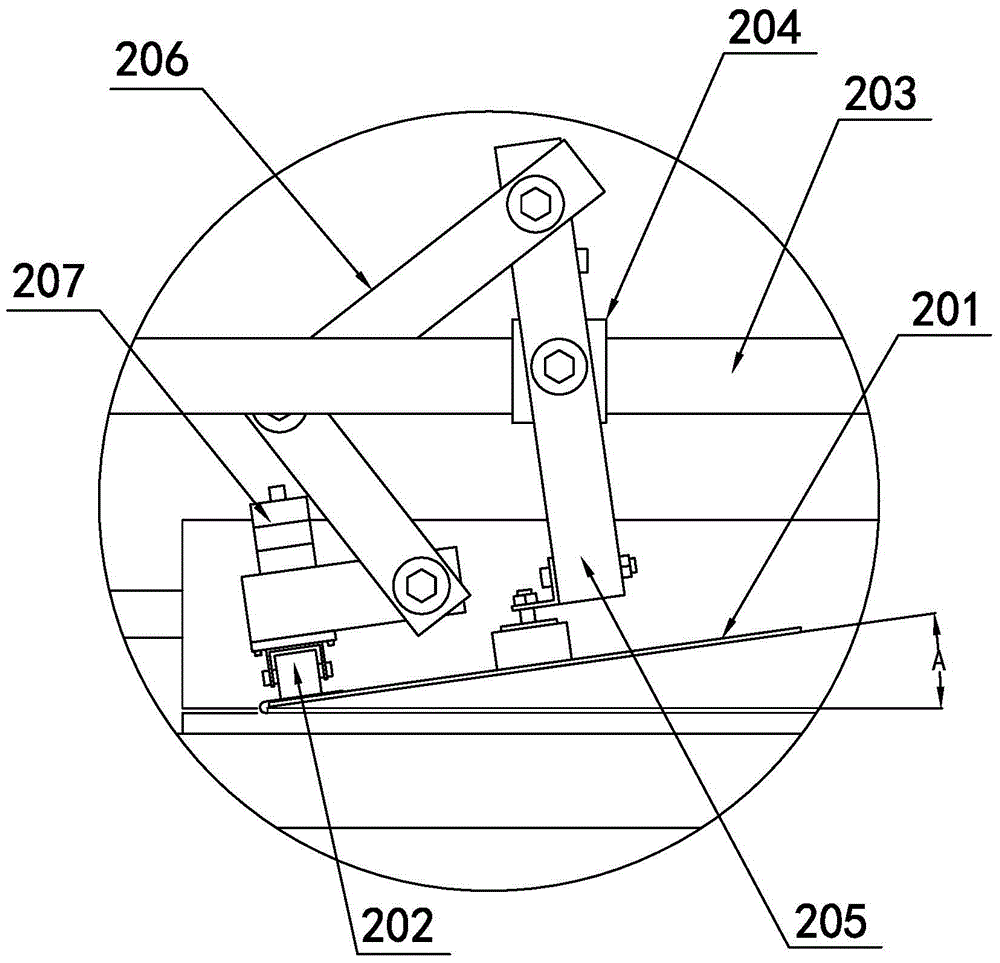

[0040] Described shaping mechanism 2 comprises disc 201, pressure wheel 202, support 203, connecting rod 205, described support 203 upper slide block 204, slide block 204 is locked by screw, thereby controls slide block 204 to slide left and right; 204 is provided with a connecting rod 205, the two are connected by screws, the connecting rod 205 can freely adjust the angle relative to the lighting panel 101, and one end of the connecting rod 205 ...

Embodiment 2

[0047] Such as Figure 6-8 As shown, a specific embodiment is provided, the pressure wheel 202 can be flexibly connected to the bracket 203 through the bracket pressure spring, the upper part of the pressure wheel 202 is provided with a guide post, the outer side of the guide post is provided with a spring 209, and the upper part of the spring 209 is provided with a guide post. There is an L-shaped support 211, the spring 209 passes through the guide post and is compressed between the pressure roller 202 and the L-shaped support 211, the upper part of the guide post is provided with a guide sleeve 210, and the pressure wheel 202 moves up and down through the guide post, spring 209, and guide sleeve 210, Thus, the pressing force of the pressing wheel 202 on the edging belt 102 is adjusted, and the edging belt 102 is shaped.

[0048] The upper part of the scraper 301 is provided with a knife rest 302, the two are connected by screws, the knife rest 302 is provided with a pin, an...

Embodiment 3

[0050] Such as Figure 9-10 As shown, a specific embodiment is provided, the pressure roller 202 can be flexibly connected to the bracket 203 through the cylinder 208, the pressure roller 202 is provided with a cylinder 208, the cylinder 208 is connected to the connecting rod 205 by screws, and the connecting rod 205 is connected to the bracket 203 by screws, and the compression force of the pressure roller 202 on the edging belt 102 is adjusted by the expansion and contraction of the cylinder 208, and the flattening of the edging belt 102 is completed, so that the raised edging belt 102 is flattened and contacts the daylighting plate 101.

[0051] An automatic edge-wrapping device for a daylighting panel production line. The working process is as follows: in the early stage of the production of the daylighting panel, the bottom film is laid, and the resin and the color paste of different colors added according to the needs are evenly stirred, then vacuumed, and then transport...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com