High-reliability white light LED plane light source module

A planar light source and white light technology, applied in the field of LED light source, can solve the problems of poor uniformity, glare, low brightness, etc., and achieve the effect of small thickness, good thermal conductivity and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

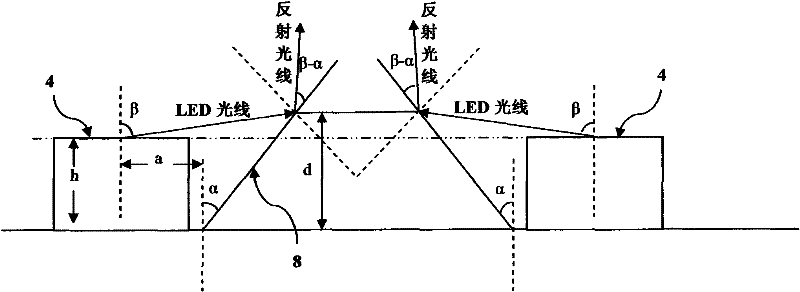

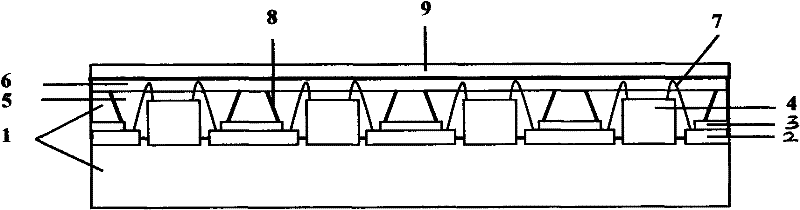

[0024] Such as figure 2 As shown, the white LED planar light source module includes: an aluminum substrate 1, a patterned copper foil circuit layer 2 and an insulating layer 3 are arranged in the middle of the aluminum substrate, and the aluminum substrate is formed on the aluminum substrate by automatic processing techniques such as laser engraving or wet and dry etching. A special trapezoidal groove structure is manufactured on the surface to create a special installation environment for the chip and realize the continuous manufacturing process of the planar light source. The bottom of the trapezoidal groove 8 is directly equipped with the LED light-emitting chip 4, adjacent to the space between the two LED light-emitting chips 4 The pitch of the LED light-emitting chip 4 is 4 mm, the height of the LED light-emitting chip 4 is h=0.5 mm, and the width of the LED light-emitting chip 4 is 0.8 mm. The horizontal distance a of the center point of the LED light-emitting chip is 0...

Embodiment 2

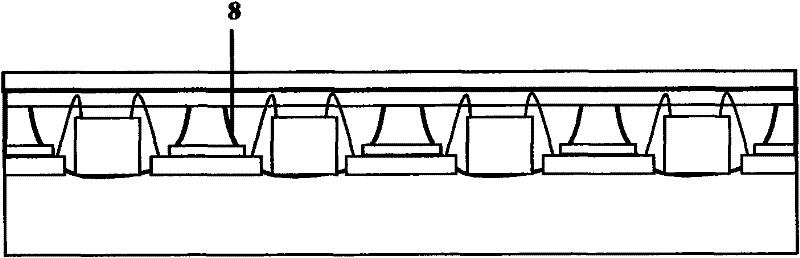

[0028] Such as image 3 As shown, the white LED planar light source module includes: an aluminum substrate 1 with a patterned copper foil circuit layer 2 and an insulating layer 03 in the middle of the aluminum substrate, and an arc-shaped groove 8 on the upper surface of the aluminum substrate with a radius of 0.5mm , the distance between adjacent LED light-emitting chips 4 is 5 mm, the thickness of the LED light-emitting chips 4 is h=0.3 mm, the width of the LED light-emitting chips 4 is 0.4 mm, a is 0.25 mm, and the depth of the arc-shaped groove 8 is d=0.5 mm, for the emitted light angle β of the light on the surface of the LED light-emitting chip that is greater than 70 degrees, the emitted light angle after reflection can be reduced to within the range of 20-60°, so as to realize the concentrated output of light;

[0029] The LED light-emitting chip is connected to the patterned copper foil circuit layer 2 through the gold wire electrode 7, and the arc-shaped groove is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com