Precise pouring device for mold slag in front of alloy electroslag smelting furnace

A technology of electroslag smelting and dumping devices, which is applied in the direction of lifting devices, lifting frames, etc., can solve problems such as inefficiency, deformation of the barrel mouth, and falling, and achieve the effects of not being easily damaged or dumped, improving stability, and setting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

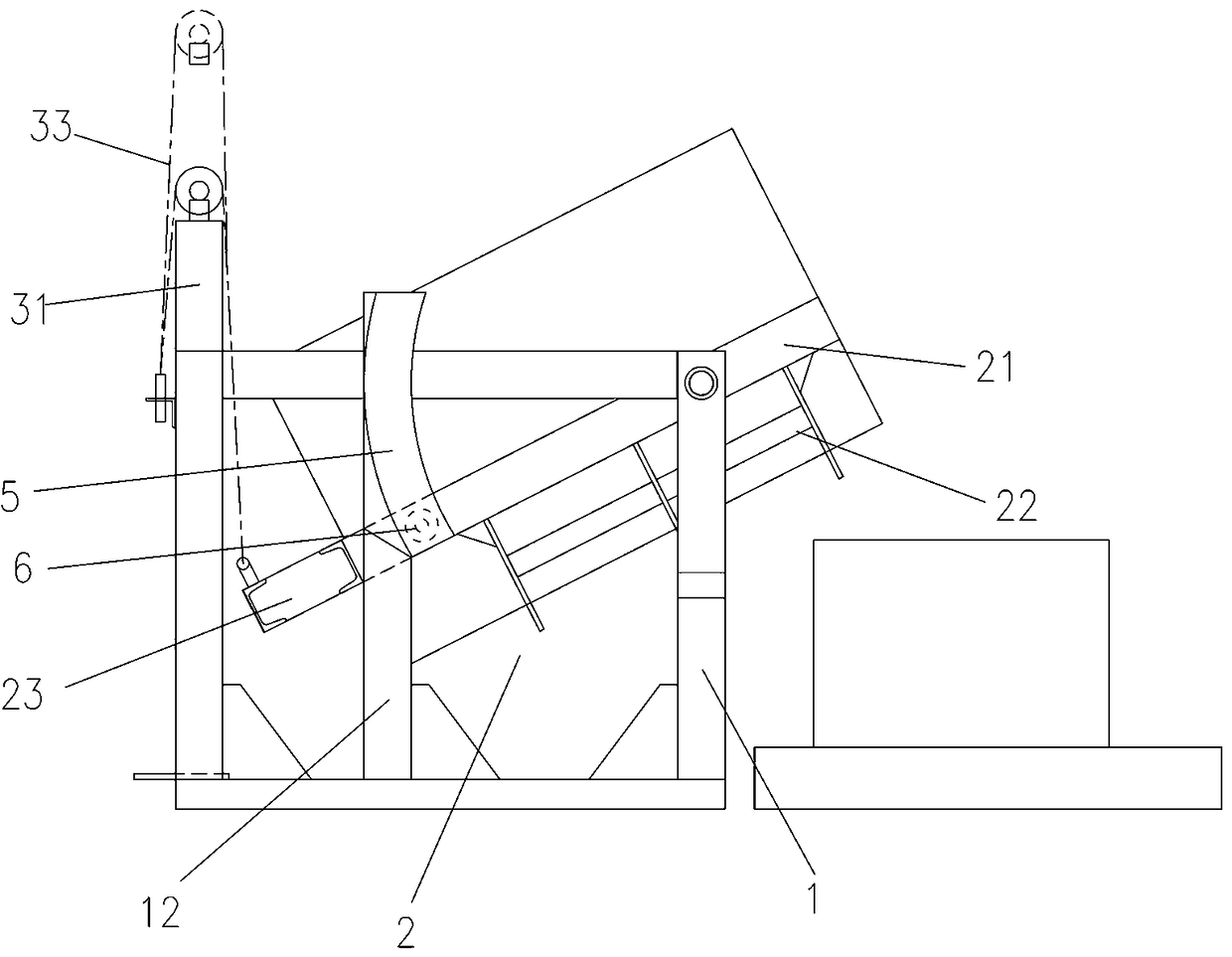

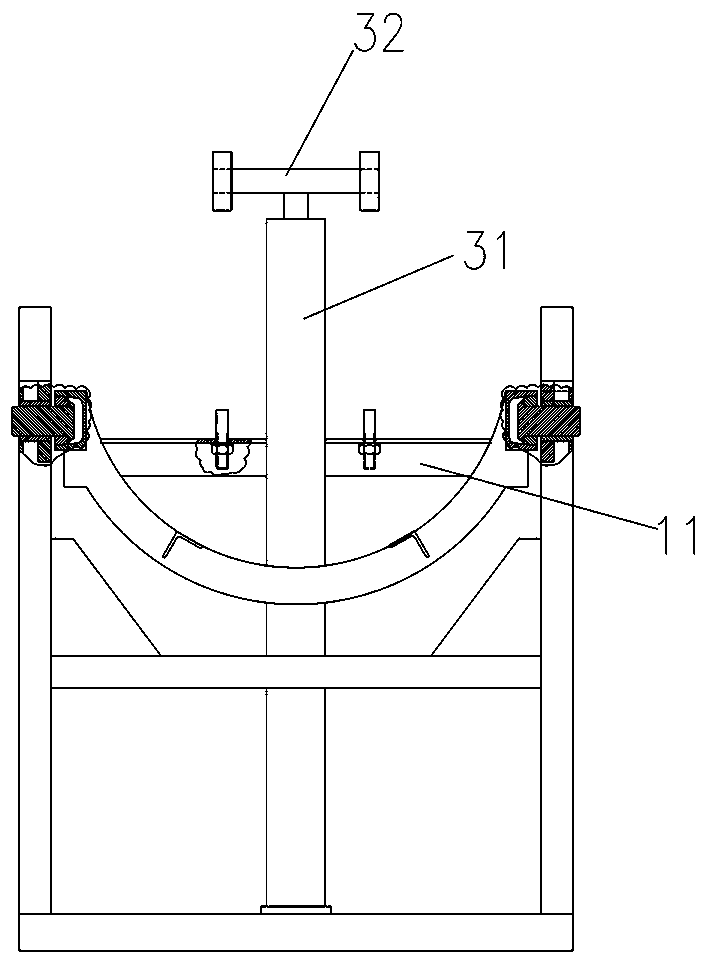

[0035]A device for accurately dumping mold slag in front of an alloy electroslag smelting furnace. At least one set of fixed locking devices on the bracket; the lifting device includes a jacking cylinder 31, an adjusting frame beam 32 with a sprocket at both ends of the piston rod top of the jacking cylinder and a chain wheel The chain 33 on the top, the two ends of the chain are fixedly connected to the rear end of the steel frame and the bracket respectively, and the distance from the front end of the bracket beyond the steel frame is less than 1 / of the length of the bracket 6.

[0036] This application uses a steel frame as the base to carry a semi-circular bracket. After placing the material bucket upside down on the bracket, cooperate with the fixed locking device to fix the material bucket, and then realize the material bucket in the material bucket by lifting the oil cylinder. It can be adjusted arbitrarily within the angle range of 20° to -30°. The front end of the ...

Embodiment 2

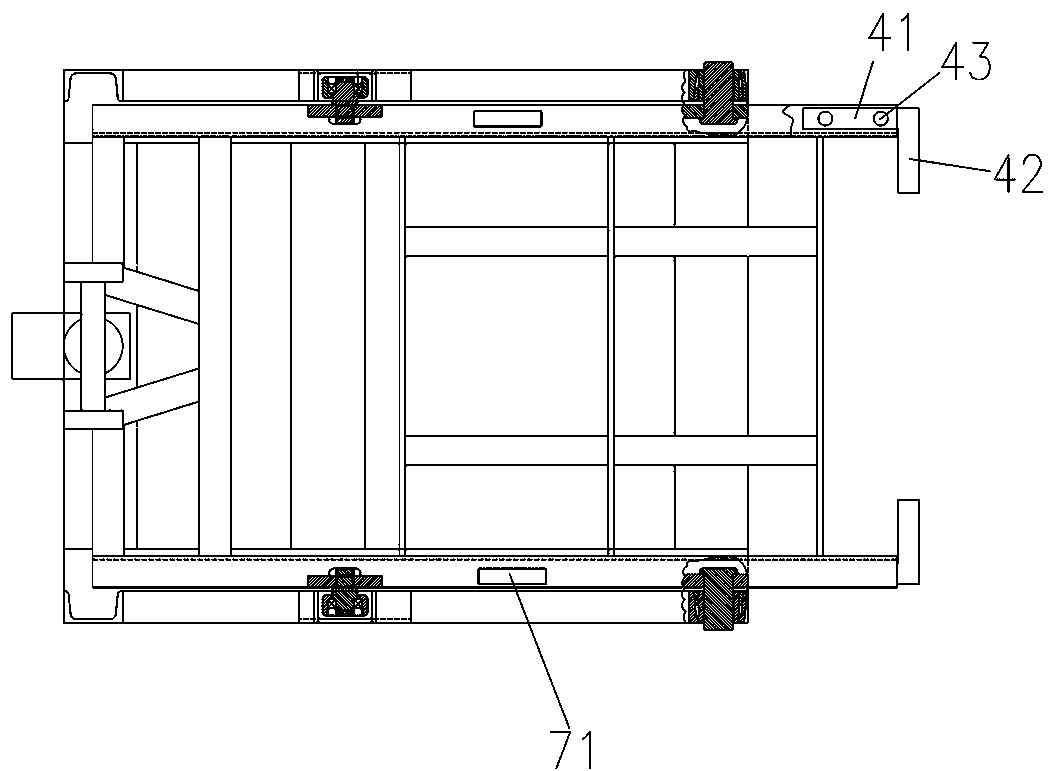

[0041] The difference from the above-mentioned embodiment is that the fixed adjustment part is connected with a precise material picking part, and the precise material picking part includes a material retainer rod 81 fixedly connected to the connecting part, and two connecting parts connected to the two sides. The adjustment frame 82 between the two retaining rods, the baffle plate 83 that can be adjusted to pass through the adjustment frame from top to bottom, and the adjustment frame is also horizontally pierced with an elastic force that is pressed against the baffle. The pressure bar 84 is supported, and the baffle plate is flush with the bucket stop part. The baffle plate is a transparent plate, and the height of the baffle plate is greater than the diameter of the mouth of the bucket. An operation hole 832 is arranged on the top of the baffle plate, and a reclaiming shovel is inserted in the operation hole.

[0042] The baffle is worn in the adjustment frame. At least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com