Imitative natural fish-belly whitish color quartz stone board and preparation method thereof

A technology of quartz stone plate and production method, applied in flat products, other household appliances, applications, etc., can solve the problems of rigidity, unnaturalness, large color difference, etc., and achieve high economic and social benefits, clear texture and high pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

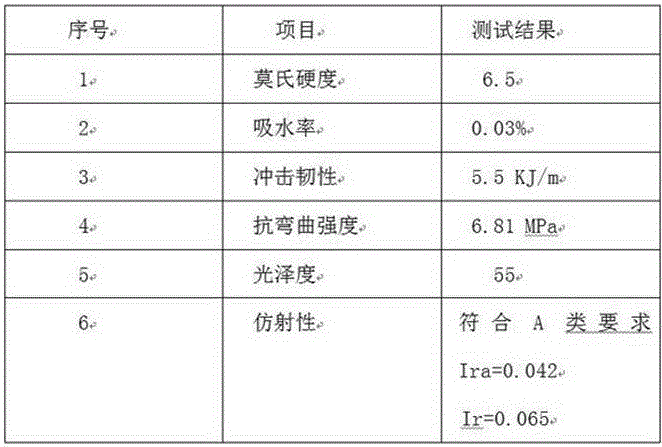

Examples

preparation example Construction

[0020] Preparation of adhesive: The adhesive is composed of the following raw materials in parts by weight: 65-70 parts of unsaturated resin, 25-30 parts of styrene, 5-10 parts of hydroxyl-o-dimethylamine, β-plasticizer 1-3 parts; Preparation method: firstly add unsaturated resin into the reaction kettle, adjust the temperature to 45-50°C, then add hydroxyl o-dimethylamine, β-plasticizer, heat up while stirring, and reach At 80-85°C, keep the temperature constant for ten minutes; when the temperature drops below 50°C and the detected viscosity reaches 4800Pa.m / s, add styrene to make the final viscosity 300-350Pa.m / s, and finally stir for 5 minutes. Can;

[0021] Mixing of materials: Add the calcined quartz sand, quartz powder and binder prepared above into the mixer according to the components; the feeding process is: first add the quartz sand and color paste and color material, after stirring for two minutes, add the binder After fully mixing evenly, add quartz powder an...

specific Embodiment approach

[0024] A natural fish maw white quartz stone slab, the parts by weight of the components are: quartz sand, 40-120 mesh, 53 parts; quartz powder: 325 mesh, 33 parts; adhesive, 11 parts; filler, 800 mesh, 4 Parts; color paste pigment, 0.8 part; dioctyl titanium phosphite ammonium, 0.2 part;

[0025] The quartz sand is composed of 40-70 mesh and 70-120 mesh quartz sand, the proportion of which is 55 parts of 40-70 mesh quartz sand and 45 parts of 70-120 mesh quartz sand;

[0026] The adhesive is composed of the following raw materials in parts by weight: 68 parts of unsaturated resin, 27 parts of styrene, 8 parts of hydroxyl o-dimethylamine, and 2 parts of β-plasticizer.

[0027] The color paste color material is prepared by the following method. First, mix the required toner with 200-mesh quartz sand, and the mixing weight ratio of the toner and quartz sand is 1:10 parts; grind, filter through a 100-mesh sieve , regrind, filter through 80 mesh screen, add into the color paste m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com