Explosion-proof glass mobile phone backboard processing technology

A technology of explosion-proof glass and processing technology, which is applied in the direction of telephone structure, lamination device, lamination auxiliary operation, etc. Scratch, improve the effect of mobile phone appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

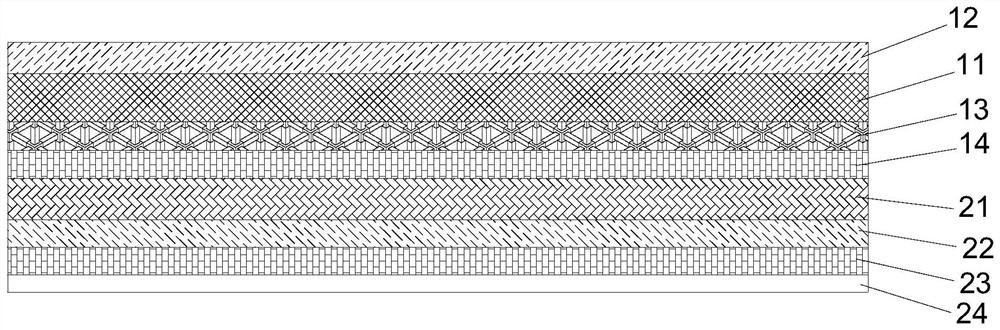

[0033] This embodiment provides a kind of explosion-proof glass mobile phone back plate processing technology, for making such as figure 1 The processing technology of the explosion-proof glass mobile phone back panel shown includes the following steps:

[0034] a, preparing the tempered glass composite ply, the preparation of the tempered glass composite ply comprises the following steps:

[0035] a1, using a tempered glass composite plate 11 with a thickness of 0.5 mm as the supporting layer;

[0036] a2. Rubbing on the front side of the tempered glass composite board 11 forms an outer texture layer 12 with a thickness of 10-18um. While the outer texture layer 12 has a texture effect, it can prevent the tempered glass composite board 11 from being scratched;

[0037] a3. Print and form a LOGO layer 13 with a thickness of 1-3um on the reverse side of the tempered glass composite board 11;

[0038] a4, performing electroplating on the LOGO layer 13 to form a first coating la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com