Cleaning-free air brick with uniform structure and manufacturing method thereof

A breathable brick, uniform technology, applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of macroscopic defects of breathable bricks, unsuitable for social industry, high slit breathable bricks, etc. Uniform pressure and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

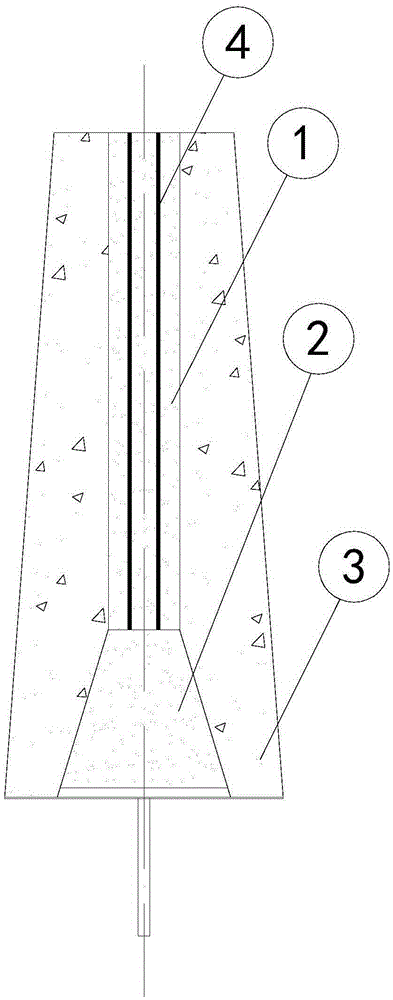

[0040] The following examples describe the present invention in detail:

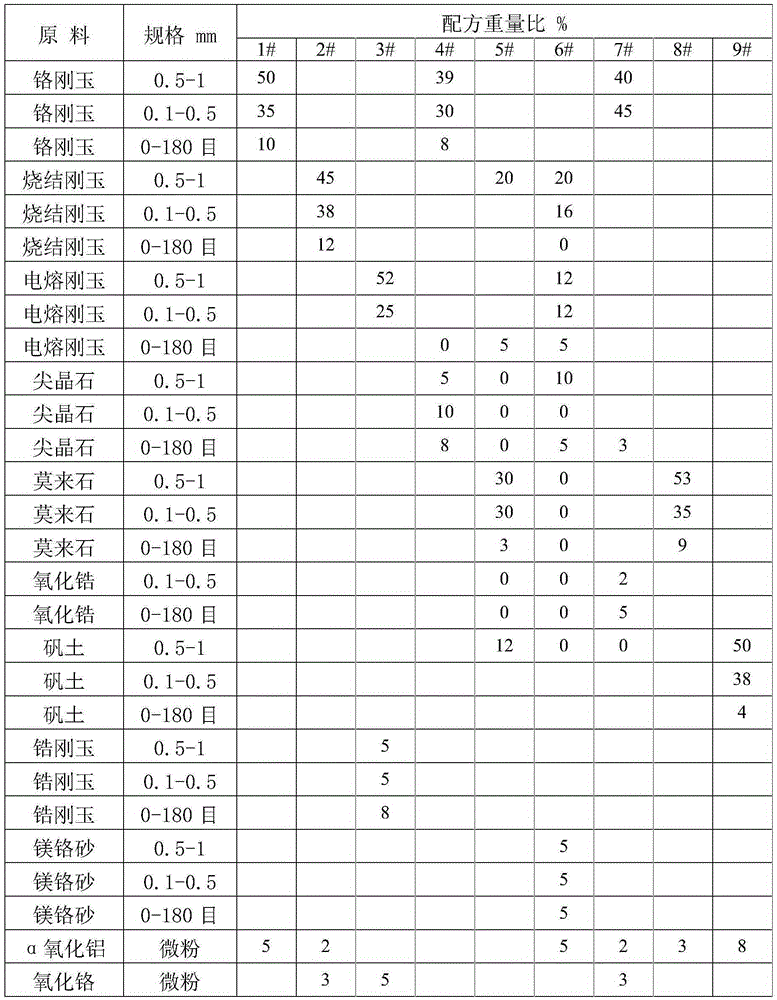

[0041] 1. Make consumable core ① and safety core ②, the ratio of raw materials is as follows:

[0042]

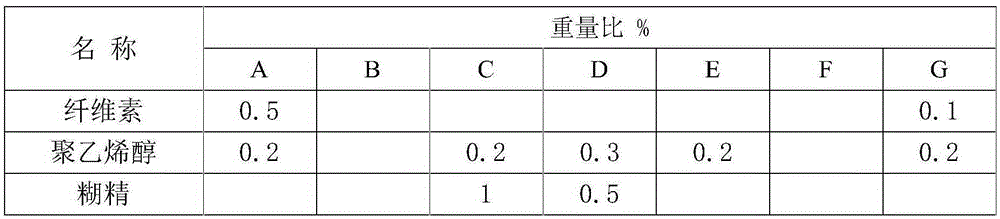

[0043] The binder ratio is as follows

[0044]

[0045]

[0046] 1.1, prepare materials according to the formula, and pre-dissolve the binder;

[0047] 1.2. When mixing and milling, first pour in the raw materials with a particle size greater than 180 mesh, mix well and then add the binder, then add the raw materials with a particle size less than or equal to 180, and mix for 5 minutes;

[0048] 1.3. Weigh a fixed amount of the mixture, add it into an elastic mold and seal it, and form it under an isostatic press.

[0049] type, the molding pressure is controlled at 65MPa, and the holding time is 20 seconds.

[0050] 1.4. Bake the consumed core ① adobe at 150°C for 12 hours after demoulding.

[0051] 1.5. Burn the adobe of the consumable core ① after demoulding at a temperature of 1650°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com