A kind of preparation method of diaminonaphthalene

A technology of diaminonaphthalene and dinitronaphthalene is applied in the field of pigments and dyes, which can solve the problems of increasing product cost and failing to take advantage of the hydrazine hydrate reduction method, and achieves lowering treatment costs, improving market competitiveness, and reducing the generation of three wastes. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of preparation method of diaminonaphthalene, and this method comprises the following steps:

[0039] Step 1, the synthesis of mixed dinitronaphthalene:

[0040] Add 246kg of sulfuric acid with a mass concentration of 76% to a 500L reactor with a stirrer, a thermometer, a reflux condenser, and a high-level dripping tank, start stirring, keep the temperature at 15-30°C, and then add dropwise a mass concentration of 98% 56.5kg of fuming nitric acid was added dropwise in 0.5h, and after mixing evenly, 45kg of naphthalene was added in batches, and the addition was completed in 2 hours. React to obtain the first reaction solution;

[0041] The first reaction liquid is lowered to normal temperature, filtered to obtain the first filtrate and the first filter cake, the first filtrate is recovered, the first filter cake is washed with water, and the crude product is beaten and purified with 200kg of toluene to obtain 76kg of mixed dinitrona...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of diaminonaphthalene, and other processes of this method are identical with embodiment 1, and difference is only in:

[0050] In this embodiment, the first organic solvent is replaced by methanol from toluene.

[0051] In the second organic solvent, methanol was replaced by ethanol, and toluene was replaced by dichloroethane.

[0052] The reflux reaction time in step 2 was 9 hours.

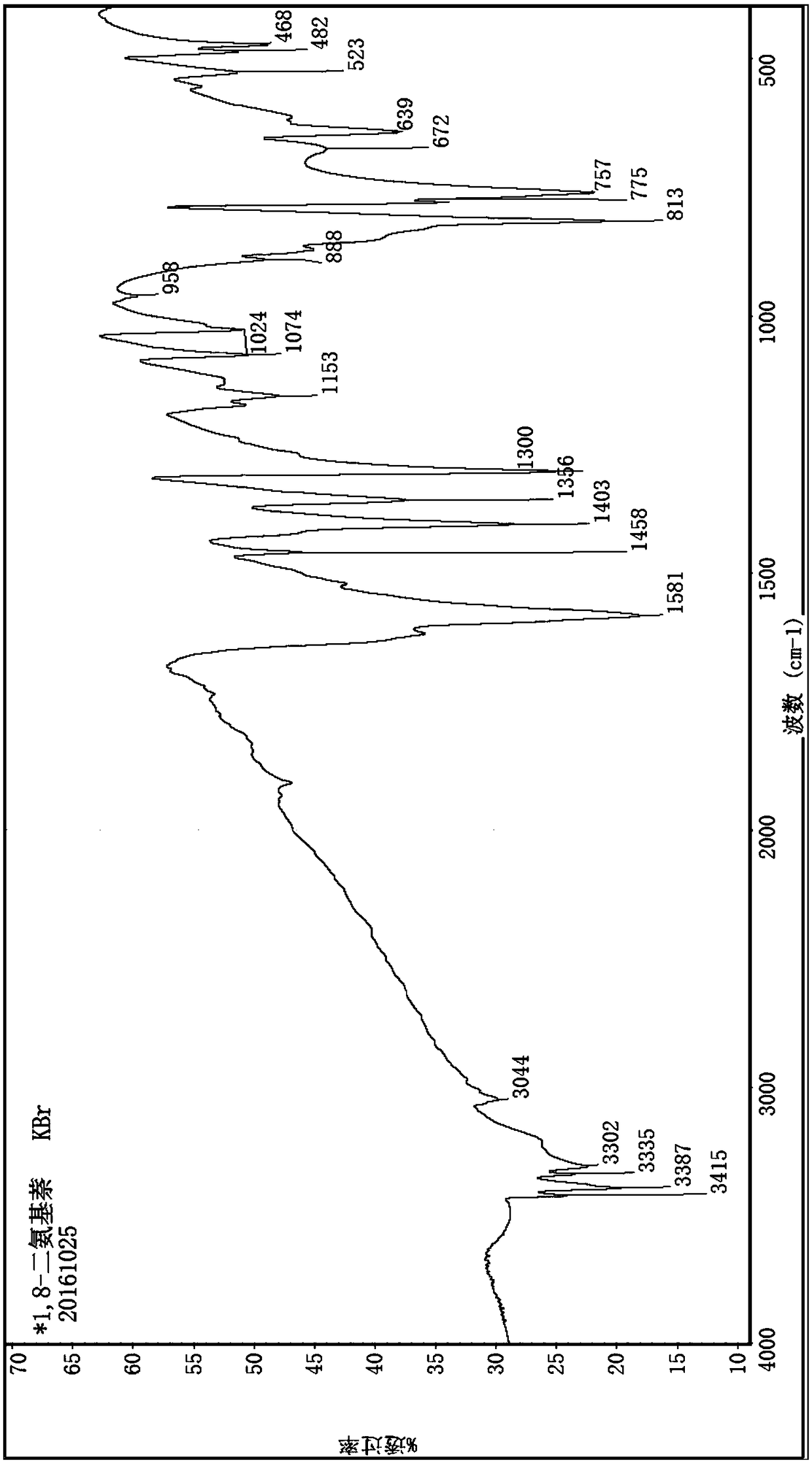

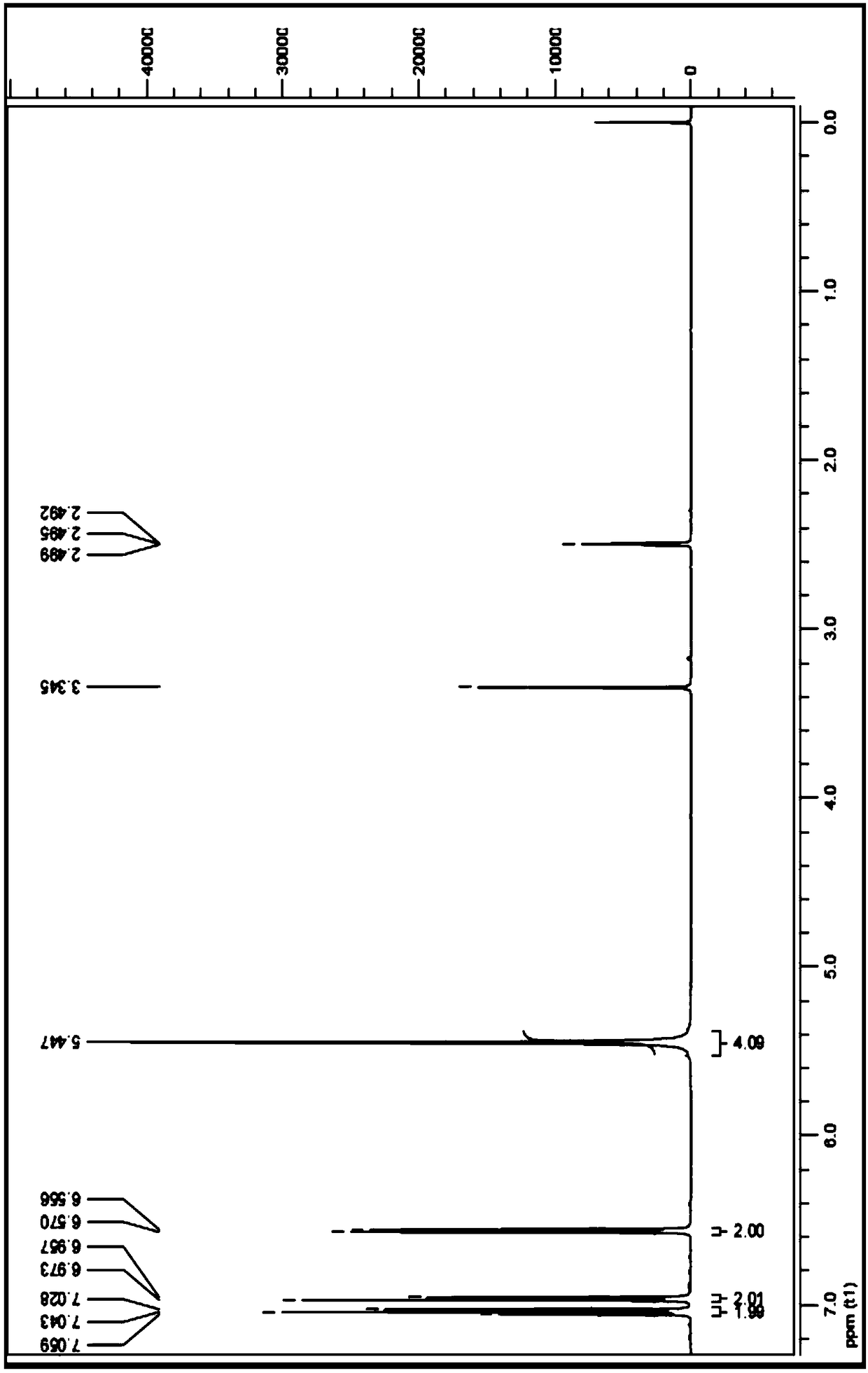

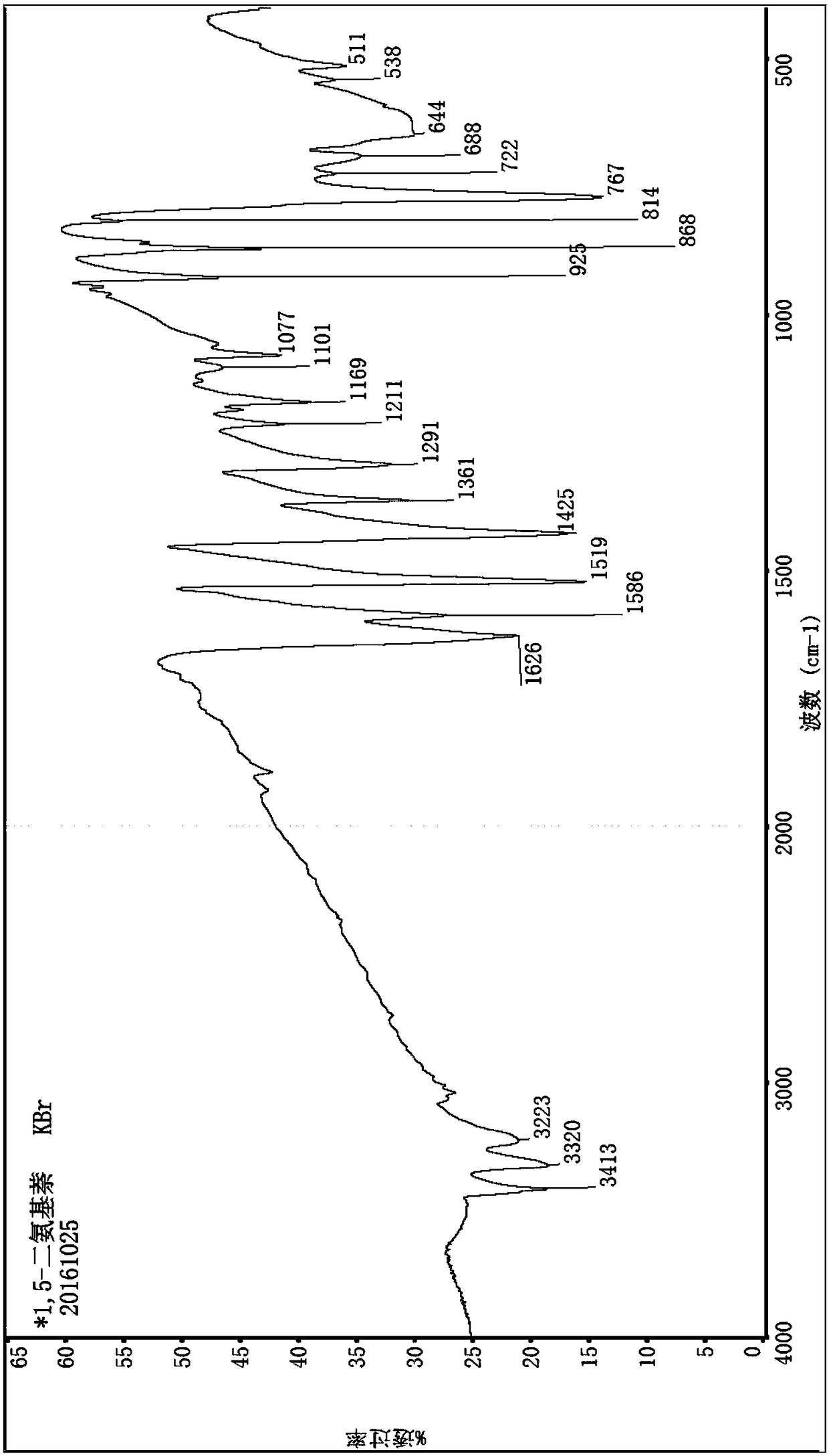

[0053] The characterization results of 1,8-diaminonaphthalene are the same as in Example 1, and the characterization results of 1,5-diaminonaphthalene are the same as in Example 1.

[0054] Based on mixed dinitronaphthalene, the yield of 1,8-diaminonaphthalene: 53%, the yield of 1,5-diaminonaphthalene: 32%, the total yield is 85%.

Embodiment 3

[0056] The present embodiment provides a kind of preparation method of diaminonaphthalene, and other processes of this method are identical with embodiment 1, and difference is only in:

[0057] In this embodiment, the first organic solvent is replaced by dichloroethane from toluene.

[0058] In the second organic solvent, change from methanol and toluene to acetone.

[0059] The reflux reaction time in step 2 is 4 hours.

[0060] The characterization results of 1,8-diaminonaphthalene are the same as in Example 1, and the characterization results of 1,5-diaminonaphthalene are the same as in Example 1.

[0061] Based on mixed dinitronaphthalene, the yield of 1,8-diaminonaphthalene: 51%, the yield of 1,5-diaminonaphthalene: 31%, the total yield is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com