Stable NDI (naphthalene diisocyanate) prepolymer as well as preparation method and application thereof

A prepolymer and stable technology, applied in the field of stable NDI prepolymer and its preparation, can solve the problems of difficult storage, loss of product performance, and deterioration of prepolymer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

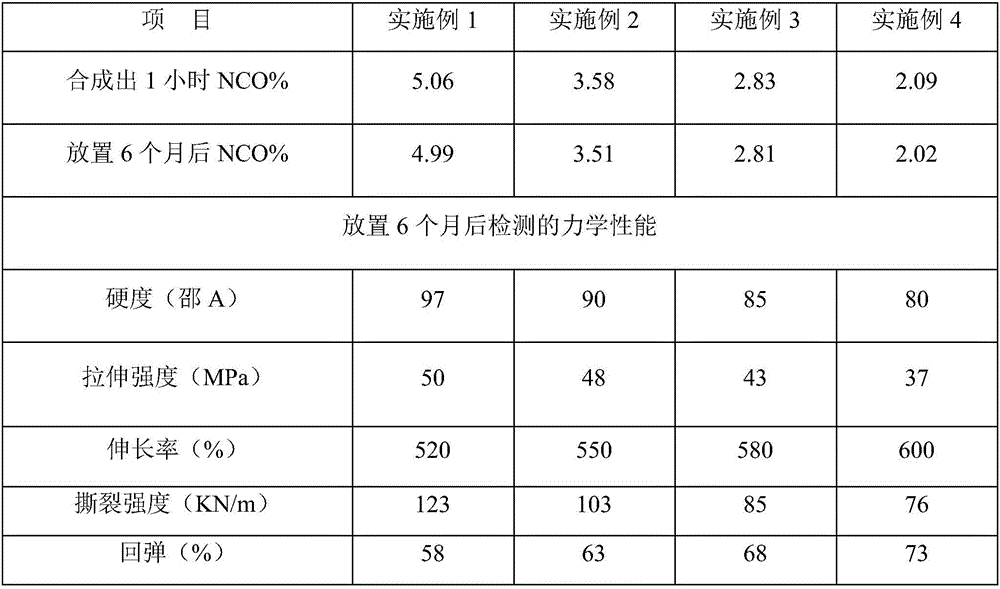

Examples

Embodiment 1

[0028] The preparation of polyester polyol is obtained by the following preparation method: in terms of weight percentage, 66.7% of adipic acid and 33.3% of ethylene glycol are added to the reaction kettle for heating, and nitrogen protection is applied. When the temperature rises to 130°C, water is produced , control the temperature at the top of the reflux tower at 102°C, and then raise the temperature to 230°C. After the water is discharged, keep it warm for 3 hours, and then use the nitrogen bubbling process to remove the water produced by polycondensation. When the acid value of the material in the kettle is less than 0.4 mg KOH / g, when the moisture content is below 0.05%, the product is qualified, and the temperature is lowered and the material is discharged to obtain a polyester polyol with a molecular weight of 1500.

[0029] The preparation method of the stable NDI prepolymer, by weight percentage, the above-prepared polyester polyol 76.4% and antioxidant 0.3% are heat...

Embodiment 2

[0032] The preparation of polyester polyol is obtained by the following preparation method: by weight percentage, 68% of adipic acid, 28.8% of ethylene glycol, and 3.2% of 1,2 propylene glycol are added to the reaction kettle for heating, and nitrogen protection is applied. When the temperature When the temperature rises to 140°C, the reaction will produce water. Control the temperature at the top of the reflux tower at 100°C, and then raise the temperature to 220°C. When the acid value of the inner material is less than 0.4mg KOH / g, and the moisture content is less than 0.05%, the product is qualified, and the material is cooled and discharged to obtain a polyester polyol with a molecular weight of 2000.

[0033] The preparation method of the stable NDI prepolymer, by weight percentage, heat the polyester polyol 82.4% and antioxidant 0.2% prepared above to 130°C, then add NDI 17.4% and mix evenly, and react at 125°C for 30 Minutes, vacuum (-0.095MPa) to remove air bubbles to ...

Embodiment 3

[0036] The preparation of polyester polyol is obtained by the following preparation method: by weight percentage, 68.3% of adipic acid, 28.5% of ethylene glycol, and 3.2% of 1,2 propylene glycol are added to the reactor for heating, and nitrogen protection is applied. When the temperature When the temperature rises to 140°C, the reaction will produce water. Control the temperature at the top of the reflux tower at 100°C, and then raise the temperature to 220°C. When the acid value of the inner material is less than 0.4mg KOH / g, and the moisture content is less than 0.05%, the product is qualified, and the material is cooled and discharged to obtain a polyester polyol with a molecular weight of 2500.

[0037] The preparation method of stable NDI prepolymer, in weight percentage, heat 85.6% of the above-prepared polyester polyol and 0.2% of antioxidant to 130°C, then add NDI 14.2% and mix evenly, react at 130°C for 30 Minutes, vacuum (-0.095MPa) to remove air bubbles to obtain N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com