Preparation method of superhydrophobic coating with favorable binding force with polyolefins

A technology of super-hydrophobic coating and polyolefin, which is applied in the direction of coating, etc., can solve the problems of insufficient scratch resistance and hydrophobic durability of the coating, and insufficient adhesion of the super-hydrophobic coating to achieve good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

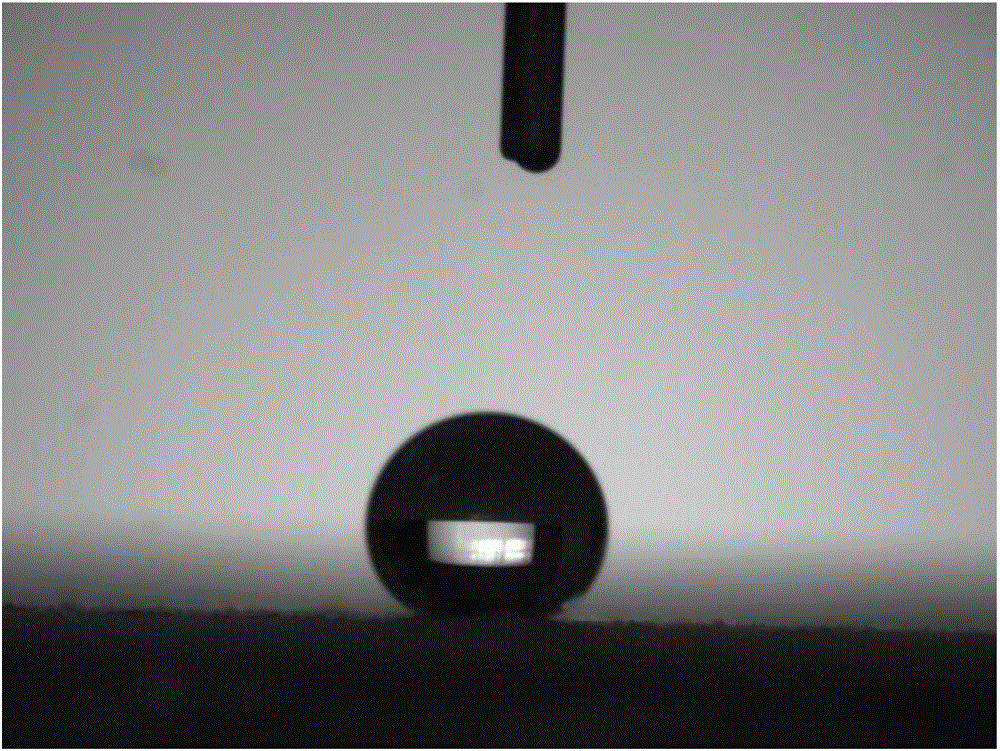

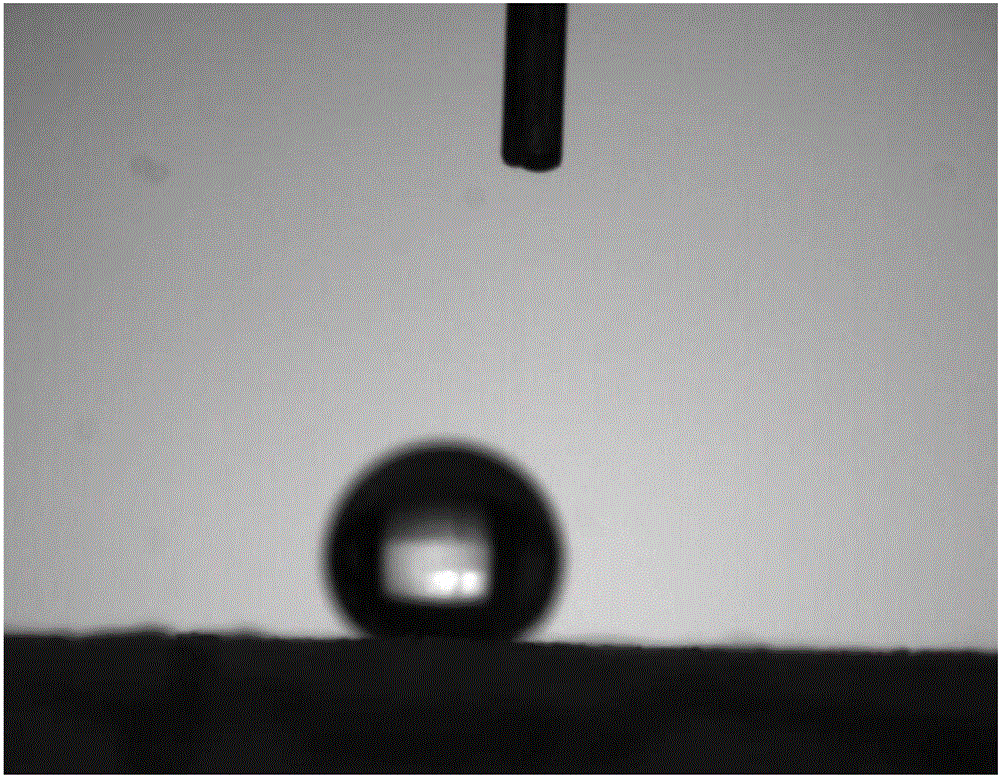

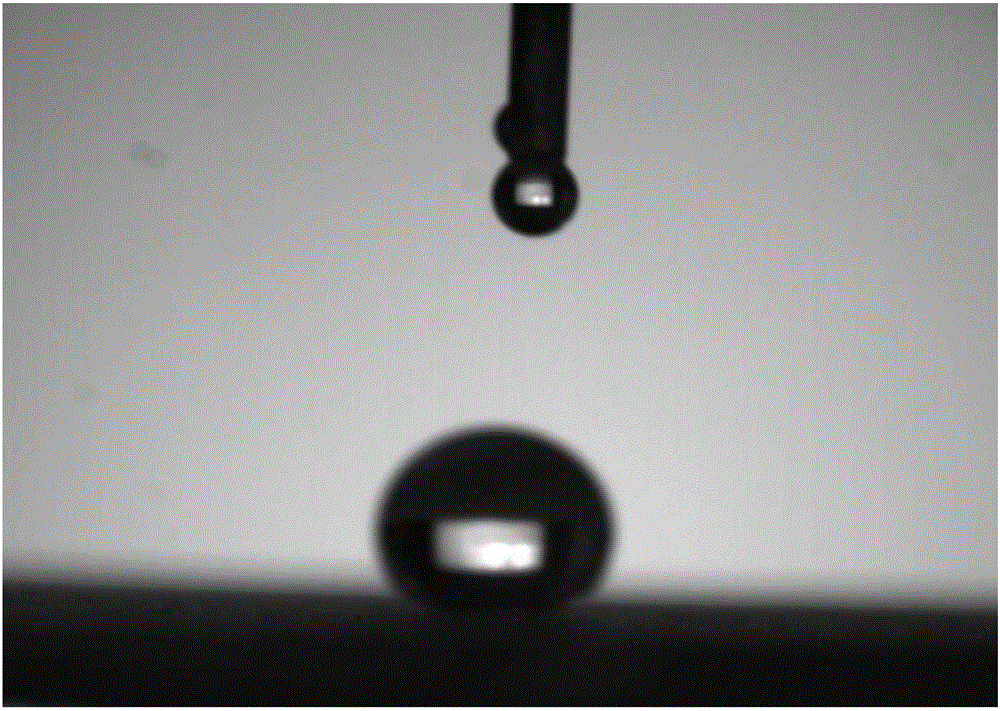

Image

Examples

Embodiment 1

[0021] (1) In terms of mass components, add 100 parts of dimethylformamide, 0.5 parts of tridecafluorooctyltrimethoxysilane, 6 parts of nano-sized titanium dioxide, 2 parts of micron-sized titanium dioxide, isopropyl triiso 0.2 parts of phthaloyl titanate, after stirring evenly, ultrasonically dispersed for half an hour, and then heated and stirred at 80°C for one hour to obtain a superhydrophobic coating.

[0022] (2) Spray the superhydrophobic coating on the polypropylene plate with a spray gun, and dry it at 20° C. for 12 hours to obtain a superhydrophobic coating.

Embodiment 2

[0026] (1) In terms of mass components, add 100 parts of dimethylformamide, 1 part of tridecafluorooctyltrimethoxysilane, 8 parts of nano-sized titanium dioxide, 4 parts of micron-sized titanium dioxide, and isopropyl tri( 0.5 part of stearoyl) titanate, stirred evenly, ultrasonically dispersed for half an hour, and then heated and stirred at 90° C. for one hour to obtain a super-hydrophobic coating.

[0027] (2) Spray the superhydrophobic coating on the polyethylene sheet with a spray gun, and dry it at 35° C. for 8 hours to obtain a superhydrophobic coating.

Embodiment 3

[0031] (1) In terms of mass components, add 100 parts of dimethylformamide, 1.5 parts of tridecafluorooctyltrimethoxysilane, 10 parts of nano-sized titanium dioxide, 6 parts of micron-sized titanium dioxide, and isopropyl tri( 0.8 parts of dioctylpyrophosphoryl) titanate were stirred evenly, ultrasonically dispersed for half an hour, and then heated and stirred at 100° C. for one hour to obtain a superhydrophobic coating.

[0032] (2) The superhydrophobic coating was sprayed on the ethylene and octene copolymer (POE) sheet with a spray gun, and dried at 50° C. for 5 hours to obtain a superhydrophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com